Modified biochar-based adsorbent with core-shell structure and preparation method thereof

A core-shell structure, biochar technology, applied in biofuels, chemical instruments and methods, other chemical processes, etc., to achieve the effects of easy transportation, significant adsorption performance, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

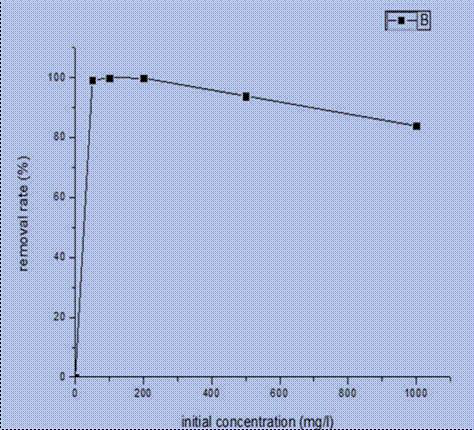

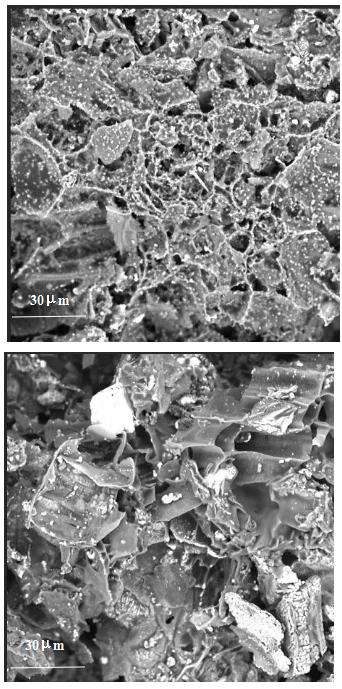

Image

Examples

Embodiment 1

[0045] a. Take the stems and leaves of sun-dried water hyacinth and crack them for 210s under the working condition of microwave cracking furnace power of 1100w to obtain the required powder biochar. 200g powder biochar, 200g phenolic resin, 150g ammonium bicarbonate, 6g alkyl dimethyl Base betaine, 20g calcium carbonate, 30g gelatin, 10g silane coupling agent KH550 are evenly mixed, then add 20 drops of alcohol and stir, after fully stirring, put the mixture into an extrusion granulator and apply 0.5MPa pressure to extrude Granulate and shape, then take out the shaped granular biochar, and place it in a microwave cracking furnace with a power of 700w for activation treatment for 150s. The nuclei of shaped activated carbon are prepared and set aside.

[0046] b. Add 25g of metal aluminum powder, 100g of PP, 5g of white oil, 1g of glass fiber, and 0.5g of polyethylene wax into a high-speed mixer and mix evenly, keeping it in a hot state (40-50 degrees Celsius) to obtain a gel m...

Embodiment 2

[0052]a. Take the stems and leaves of sun-dried water hyacinth and crack them for 210s under the working condition of microwave cracking furnace power of 1100w to obtain the required powder biochar. 200g powder biochar, 180g phenolic resin, 150g ammonium bicarbonate, 6g alkyl dimethyl Base betaine, 20g calcium carbonate, 30g gelatin, 10g silane coupling agent KH550 are evenly mixed, then add 20 drops of alcohol and stir, after fully stirring, put the mixture into an extrusion granulator and apply 0.5MPa pressure to extrude Granulate and shape, then take out the shaped granular biochar, and place it in a microwave cracking furnace with a power of 700w for activation treatment for 150s. The nuclei of shaped activated carbon are prepared and set aside.

[0053] b. Add 20g of metal aluminum powder, 100g of PP, 5g of white oil, 1g of glass fiber, and 0.5g of polyethylene wax into a high-speed mixer and mix evenly, keeping it in a hot state (40-50 degrees Celsius) to obtain a gel ma...

Embodiment 3

[0059] a. Take the stems and leaves of sun-dried water hyacinth and crack them for 210s under the working condition of microwave cracking furnace power of 1100w to obtain the required powder biochar. Base betaine, 20g calcium carbonate, 30g gelatin, 10g silane coupling agent KH550 are evenly mixed, then add 20 drops of alcohol and stir, after fully stirring, put the mixture into an extrusion granulator and apply 0.5MPa pressure to extrude Granulate and shape, then take out the shaped granular biochar, and place it in a microwave cracking furnace with a power of 700w for activation treatment for 150s. The nuclei of shaped activated carbon are prepared and set aside.

[0060] b. Add 20g of metal aluminum powder, 100g of PP, 5g of white oil, 1g of glass fiber, and 0.5g of polyethylene wax into a high-speed mixer and mix evenly, keeping it in a hot state (40-50 degrees Celsius) to obtain a gel material;

[0061] c. Put the core body into the gel material and stir (5min); take out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com