Three-dimensional conductive skeleton and preparation method and application thereof

A framework, three-dimensional technology, applied in the field of three-dimensional conductive framework and its preparation, to achieve the effect of improving battery safety performance, sufficient electrical contact, and increasing cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

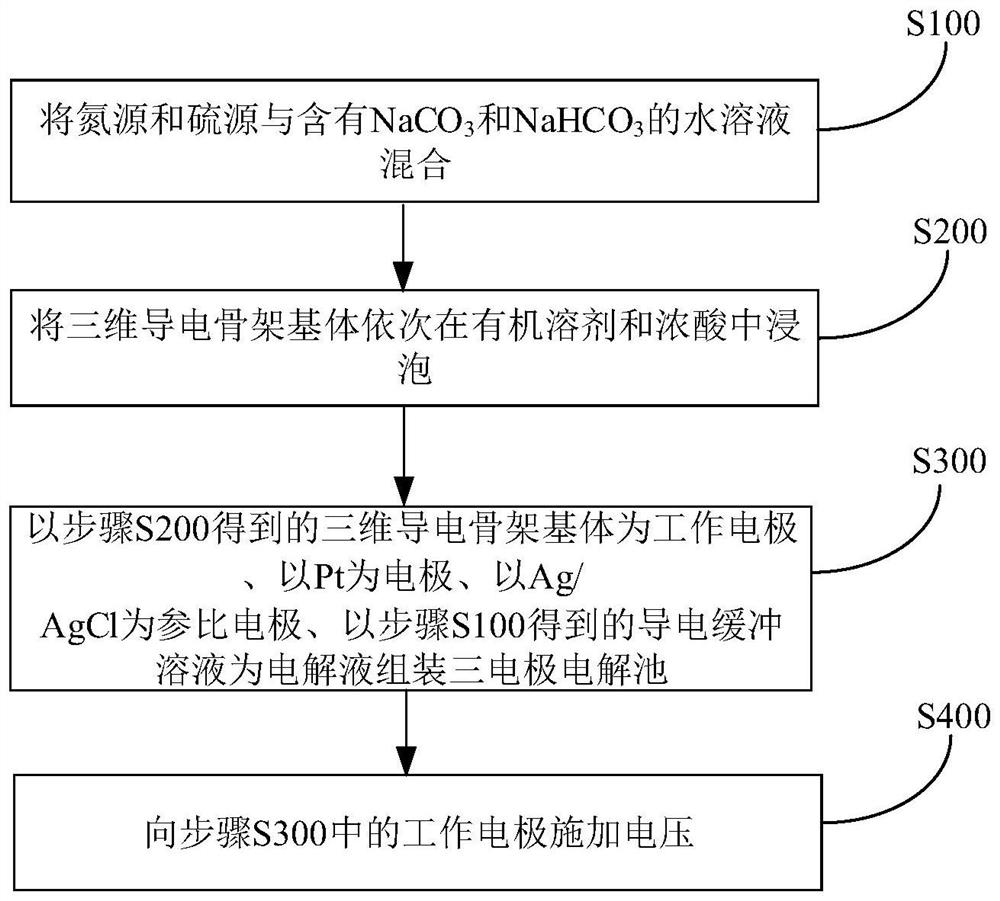

[0047] According to the method for preparing a three-dimensional conductive framework according to an embodiment of the present invention, the three-dimensional conductive framework matrix is sequentially soaked in an organic solvent and concentrated acid, washed and dried, and then the three-dimensional conductive framework matrix obtained after drying is used as a working electrode, and Pt As the counter electrode, with Ag / AgCl as the reference electrode, to include nitrogen source, sulfur source, NaCO 3 and NaHCO 3 The conductive buffer solution is used as the electrolyte to assemble a three-electrode electrolytic cell, and a voltage is applied to the working electrodes. After heat treatment, nitrogen and sulfur elements are doped on the surface of the three-dimensional conductive framework. These two elements can co-dope the surface of the three-dimensional conductive framework matrix to form a variety of chemical bonds, thereby reducing its surface energy and reducing t...

Embodiment 1

[0055] The method for preparing lithium metal negative electrode:

[0056] (1) 10.60g Na 2 CO 3 and 8.40g of sodium bicarbonate were dissolved in 100ml of deionized water, and stirred evenly until completely dissolved;

[0057] (2) 2.4g ammonium nitrate and 3.3g cysteine are slowly added in the solution of above-mentioned step (1);

[0058] (3) Soak the carbon cloth in acetone for 1 hour, then wash off the acetone with ethanol, wash with deionized water to remove ethanol, and put it in an oven to dry;

[0059] (4) immerse the dried carbon cloth in concentrated nitric acid with a mass fraction of 60%, soak for 60 minutes, wash to neutral with deionized water, and dry for subsequent use;

[0060] (5) The carbon paper obtained in the above step (4) is used as a working electrode, the Pt electrode is used as a counter electrode, the Ag / AgCl electrode is used as a reference electrode, and the solution obtained in step (2) is used as an electrolyte to make a three-electrode ele...

Embodiment 2

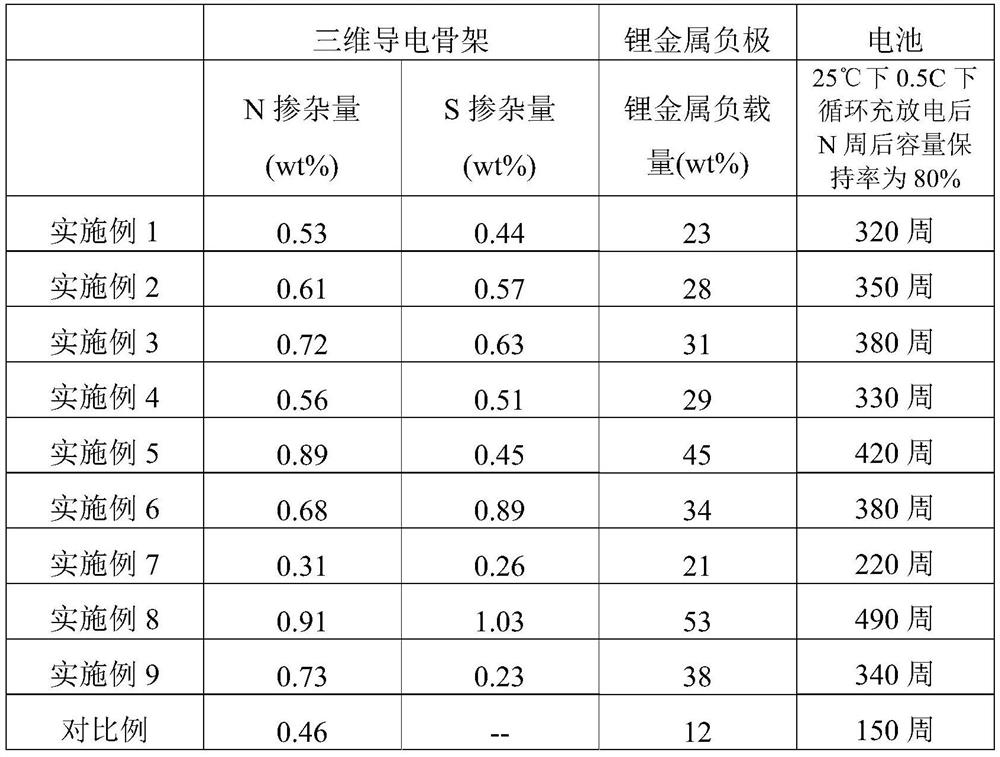

[0065] The method for preparing the lithium metal negative electrode is the same as in Example 1, except that 1.8 g of ammonium nitrate and 3.8 g of cysteine are slowly added to the solution of step (1) and step (6) in step (2) of Example 2. The applied voltage time is 45min, the N doping amount of the modified carbon cloth is 0.61wt%, and the S doping amount is 0.57wt%. A lithium metal negative electrode loaded with lithium metal is obtained (the loading amount of metal lithium is 28wt%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com