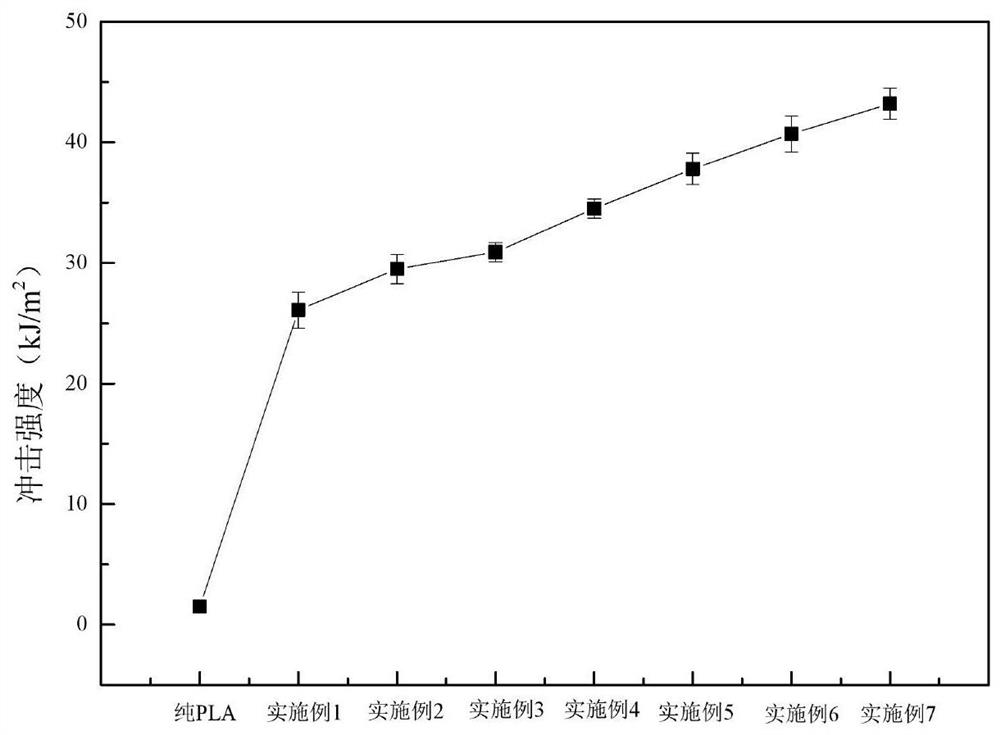

High-toughness flame-retardant PLA composite material and preparation method thereof

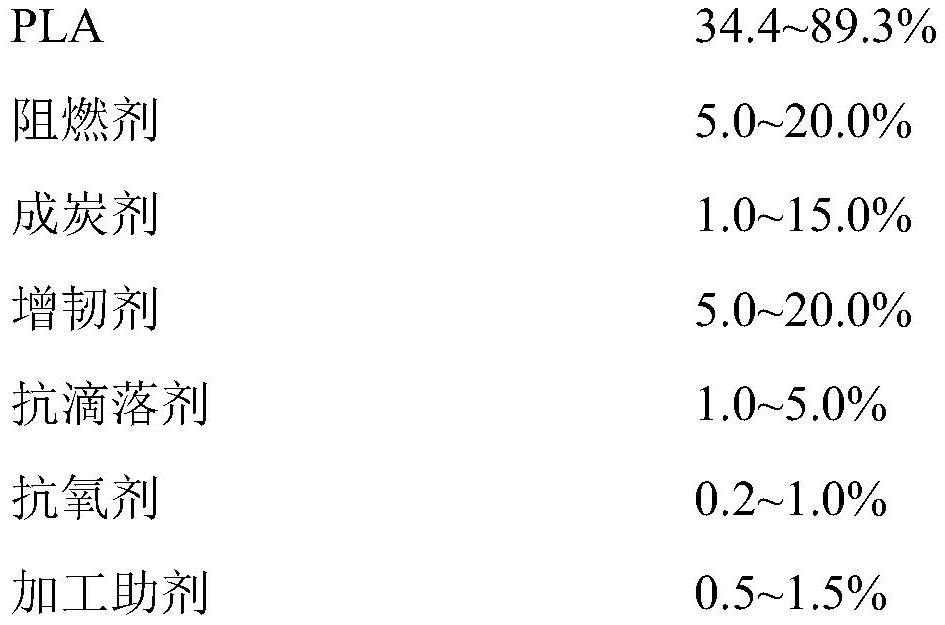

A composite material, PLA34.4 technology, applied in the field of high-tough flame-retardant PLA composite materials and its preparation, can solve the problems of cumbersome operation, complicated preparation process, unfavorable promotion and application, etc., to save resources, reduce costs, and suppress dripping The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

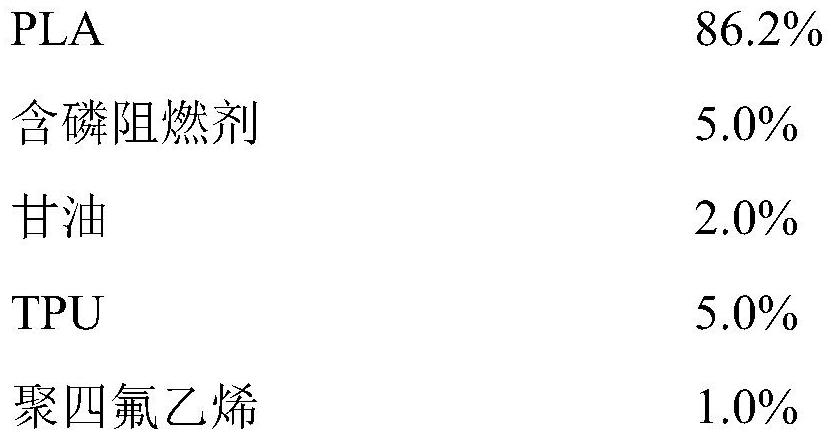

Embodiment 1

[0025]

[0026]

[0027] (1) According to the above weight percentage, put the PLA pellets, phosphorus-containing flame retardant, glycerin, and TPU in a vacuum oven at 80°C for 12 hours and take them out for later use.

[0028] (2) According to the above ratio, put PLA, phosphorus flame retardant, glycerin, TPU, polytetrafluoroethylene, antioxidant 168 and processing aid into the torque rheometer at a speed of 80r / min and mix for 10min according to the ratio, Mix it well.

[0029] (3) Put the homogeneously mixed materials in the above step (2) into a twin-screw extruder with a rotating speed of 200r / min and a temperature of 180-220°C for extrusion molding, and cool and pelletize after air-drying. Specimens for limiting oxygen index, vertical combustion flame retardant test and impact performance test were prepared by laser cutting.

Embodiment 2

[0031]

[0032] (1) According to the above weight percentage, put PLA pellets, phosphorus-containing flame retardant, pentaerythritol, and PCL in a vacuum oven at 75°C for 16 hours and take them out for later use.

[0033] (2) According to the above ratio, put PLA, phosphorus flame retardant, pentaerythritol, PCL, polytetrafluoroethylene, antioxidant 168 and processing aid into the torque rheometer at a speed of 80r / min according to the ratio and mix for 10min. Mix it well.

[0034] (3) Put the homogeneously mixed material in the above step (2) into a twin-screw extruder with a rotation speed of 220r / min and a temperature of 180-220°C for extrusion molding, and cool and pelletize after air-drying. Specimens for limiting oxygen index, vertical combustion flame retardant test and impact performance test were prepared by laser cutting.

Embodiment 3

[0036]

[0037]

[0038] (1) According to the above weight percentage, put PLA pellets, silicon-containing flame retardant, glycerin: pentaerythritol = 1:1 (wt%), TPU, put them in a vacuum oven at 60°C for 24 hours and take them out for later use.

[0039] (2) According to the above proportions, put PLA, silicon-containing flame retardant, glycerin: pentaerythritol = 1:1 (wt%), TPU, polytetrafluoroethylene, antioxidant 1010 and processing aids according to the proportion into the rotating speed of 90r / min in a torque rheometer for 7 minutes to make it evenly mixed.

[0040] (3) Put the homogeneously mixed material in the above step (2) into a twin-screw extruder with a rotation speed of 220r / min and a temperature of 180-220°C for extrusion molding, and cool and pelletize after air-drying. Specimens for limiting oxygen index, vertical combustion flame retardant test and impact performance test were prepared by laser cutting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com