Bi-component catalytic system for high-activity preparation of polyether polyol or polyether ester polyol, and application of bi-component catalytic system

A technology of polyether ester polyol and polyether polyol, which is applied in the field of catalytic systems, can solve problems such as inability to balance high selectivity and high activity, unsatisfactory results, and low number-average molecular weight of polyester. Achieve the effect of realizing polymerization selectivity and precise regulation of molecular weight, shortening induction period, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

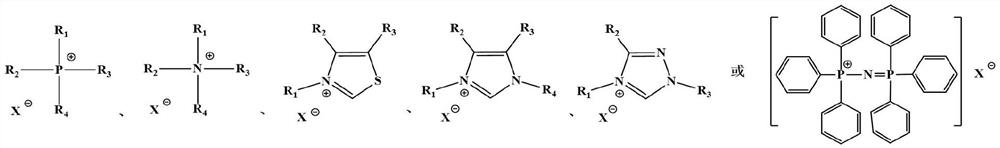

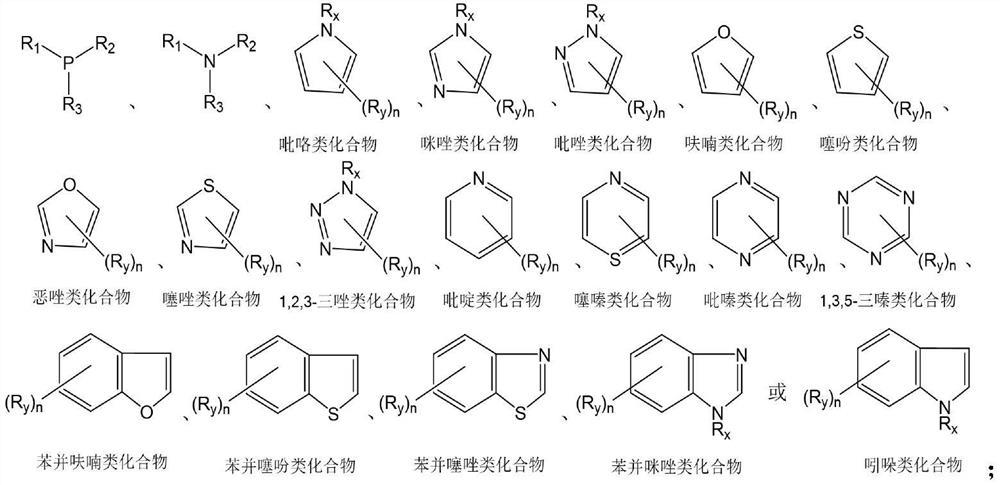

Method used

Image

Examples

Embodiment 1

[0057] The preparation of the double metal cyanide catalyst (DMC catalyst) refers to the method disclosed in Example 1 of the patent CN102179262A.

Embodiment 2

[0059] Preparation of polyether ester polyols:

[0060]

[0061] Add the DMC catalyst that 10mg embodiment 1 prepares in the dry autoclave, promotor: 3.32mg tetrabutylammonium bromide (TBAB: DMC=1:1mol / mol), epoxy compound: 100mL propylene oxide ( PO, 83g), starter: 20g polyether polyol (polypropylene glycol 400, referred to as: PPG-400), cyclic acid anhydride compound: 15g phthalic anhydride (PA) (the mol ratio of acid anhydride and epoxy compound is 0.07:1), then close the reactor, fill the high pressure reactor with CO 2 Gas, when the temperature in the kettle is stabilized at about 100°C, the system pressure does not change any more and is stable at about 5MPa. After reacting for 4 hours, cool down to room temperature and remove the gas in the kettle to obtain polyether ester polyol.

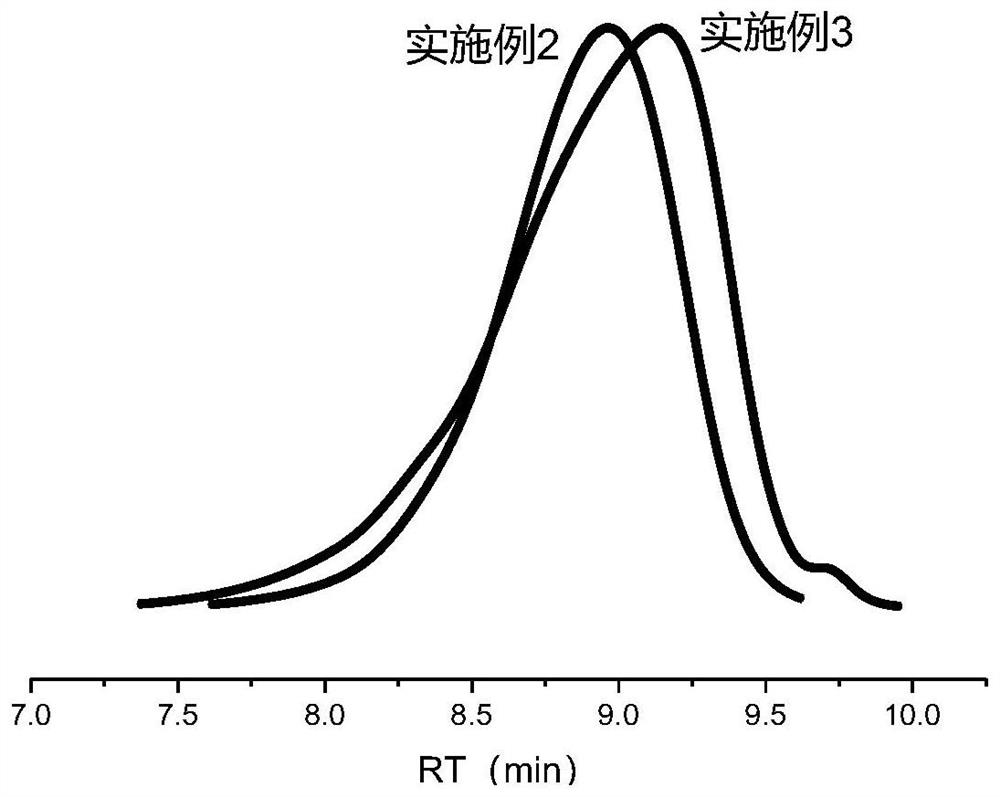

[0062] The carbonate unit content was calculated by proton nuclear magnetic spectrum, and the molecular weight and its distribution were obtained by gel permeation chromatography test, a...

Embodiment 3

[0064] Polymerization operation and polyol analysis are the same as in Example 2, except that no accelerator is added.

[0065] figure 1 It shows that adding the accelerator (Example 2) has a narrower molecular weight distribution than the polyetherester polyol prepared without adding the accelerator (3), and the molecular weight tailing phenomenon is obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com