Laser connection method for metal/carbon fiber reinforced thermoplastic composite material

A composite material and connection method technology, which is applied in the field of composite processing of metal/carbon fiber reinforced thermoplastic composite materials, can solve the problems of weak chemical bonding strength, low joint strength, and inconspicuous interface mechanical fitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

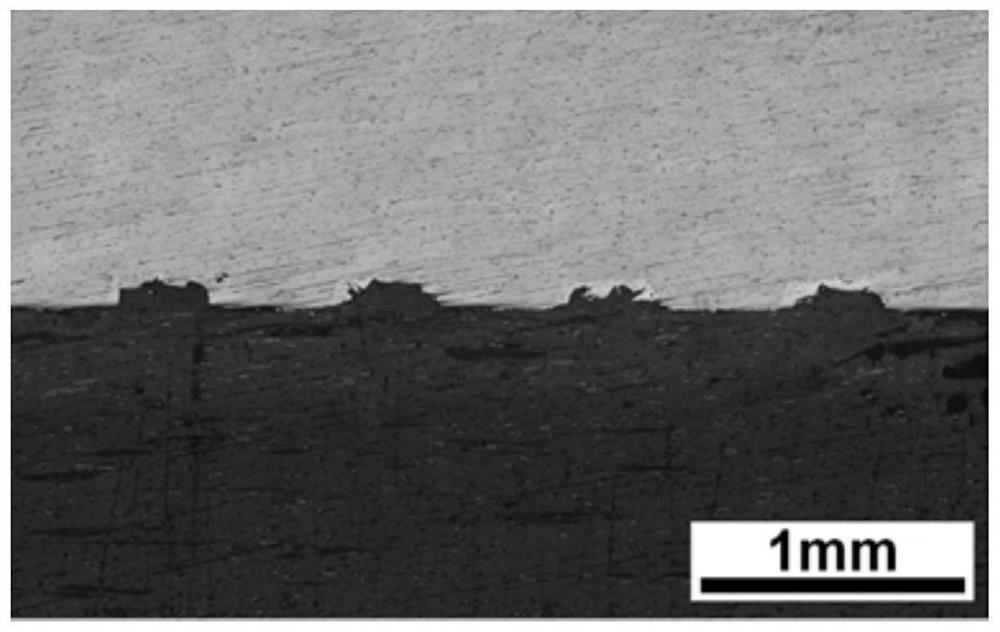

[0032] This embodiment provides a metal / carbon fiber reinforced thermoplastic composite material laser connection method, and uses this method to complete the laser connection of TC4 titanium alloy and carbon fiber reinforced polyether ether ketone (CF-PEEK), specifically including the following steps:

[0033] Step 1. Place the TC4 titanium alloy substrate and CF-PEEK plate to be connected in an ultrasonic cleaning container, and clean them in a mixed solution of acetone and alcohol for 60 seconds to remove surface oil, and then place the cleaned CF-PEEK plate on the Dry in an oven at 80°C for 2 hours, place the TC4 titanium alloy substrate in a mixed solution consisting of 80% distilled water, 15% nitric acid and 5% hydrofluoric acid by volume, and wash for 30 seconds to remove the surface oxide film, then Blow dry with a hair dryer;

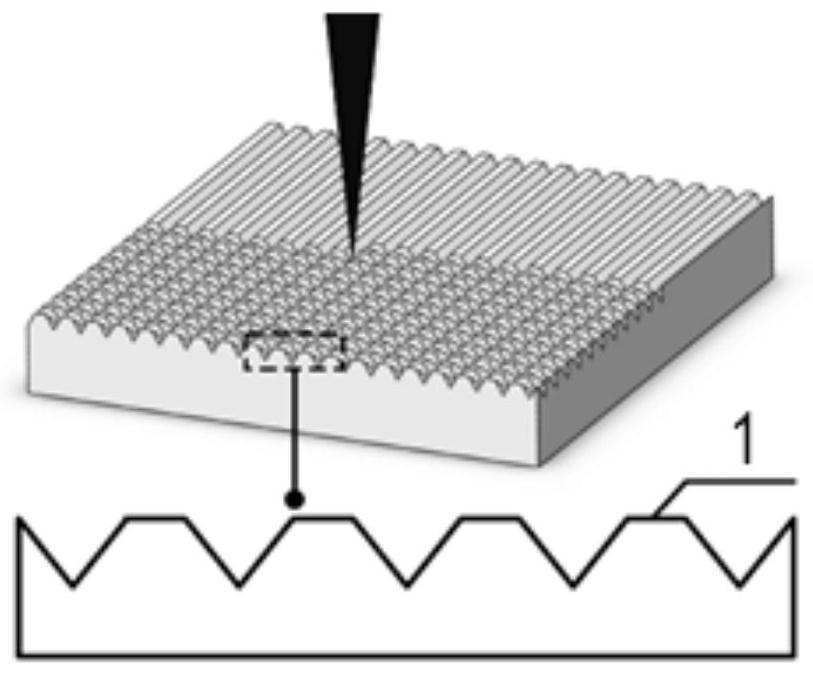

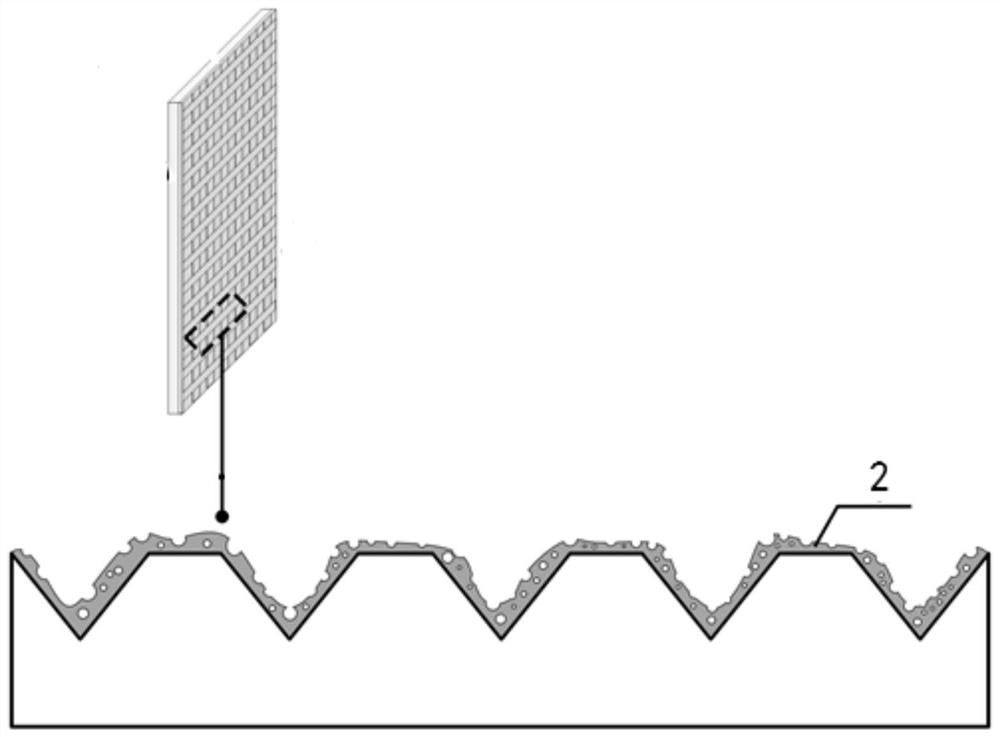

[0034] The nanosecond laser processing system is used to ablate the surface of the above-mentioned TC4 substrate to produce a grid-like micro...

Embodiment 2

[0045] This embodiment provides a metal / carbon fiber reinforced thermoplastic composite material laser connection method, and uses this method to complete the laser connection of 304 stainless steel and carbon fiber reinforced nylon (CF-PA), specifically including the following steps:

[0046] Step 1. Place the 304 stainless steel substrate and the CF-PA plate to be connected in an ultrasonic cleaning container, and wash them in a mixed solution of acetone and alcohol for 60 seconds to remove surface oil, and then place the cleaned CF-PA plate in Dry in a drying oven at 100°C for 4 hours, place the 304 stainless steel substrate in a mixed solution composed of 80% distilled water, 15% nitric acid and 5% hydrofluoric acid by volume, and clean it for 60 seconds to remove the surface oxide film, and then use a hair dryer blow dry;

[0047] A nanosecond laser processing system was used to ablate the surface of the above-mentioned 304 stainless steel substrate to produce a groove-li...

Embodiment 3

[0053] This embodiment provides a metal / carbon fiber reinforced thermoplastic composite material laser connection method, and uses this method to complete the laser connection of 6061 aluminum alloy and carbon fiber reinforced polyethylene terephthalate (CF-PET), specifically including Follow the steps below:

[0054] Step 1. Place the 6061 aluminum alloy substrate and CF-PET plate to be connected in an ultrasonic cleaning container, and clean them for 30 seconds in a mixed solution of acetone and alcohol in any proportion to remove surface oil, and then place the cleaned CF-PET plate on the Dry in an oven at 80°C for 2 hours, place the 6061 aluminum alloy substrate in a mixed solution consisting of 80% distilled water, 15% nitric acid and 5% hydrofluoric acid by volume, and wash for 40 seconds to remove the surface oxide film, then Blow dry with a hair dryer;

[0055] The nanosecond laser processing system is used to ablate the surface of the above-mentioned 6061 aluminum al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com