Three-dimensional porous NiO/NF active material, preparation method and application thereof, and device for removing heavy metal ions in wastewater by electrocoagulation method

A heavy metal ion, three-dimensional porous technology, used in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of low mechanical strength, immaturity and high cost of membranes, and achieve flexible and flexible performance, improve practicability, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

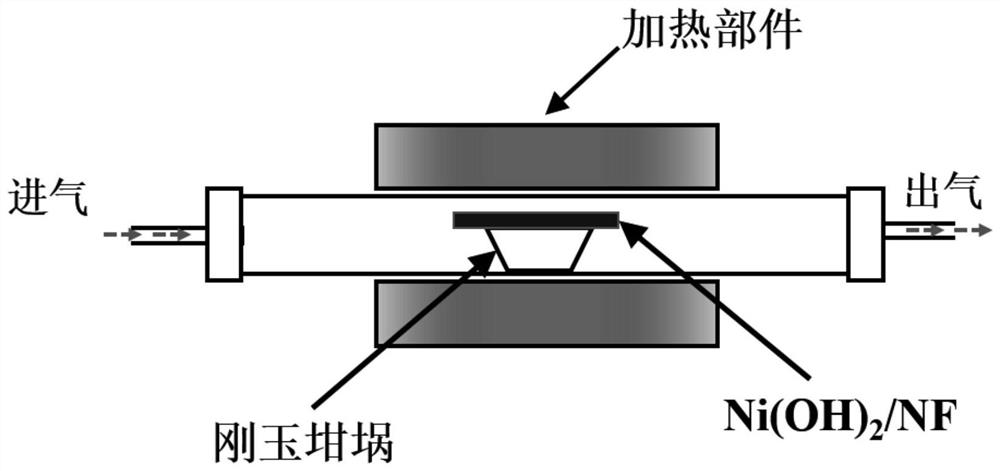

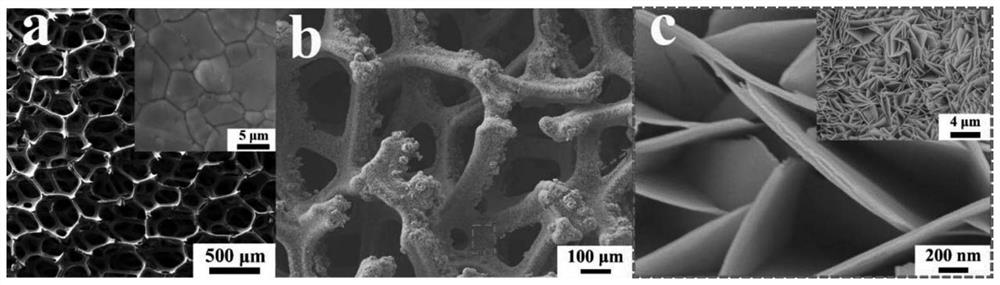

[0056] A NiO / NF active material with a three-dimensional porous structure, the active material can be directly used as an active electrode anode, electrocoagulation to remove heavy metal ions in industrial wastewater, and its preparation includes the following steps:

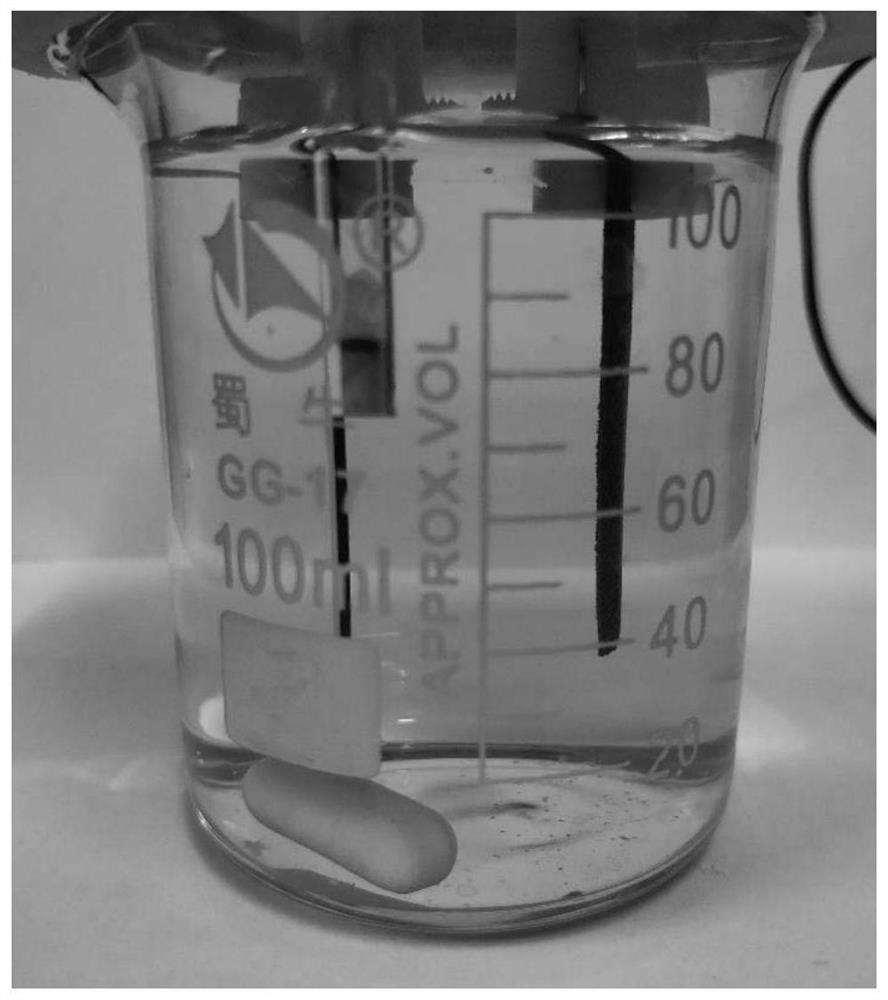

[0057] s11. Pretreatment of foamed nickel: put the cut 40mm*20mm*1.5mm foamed nickel in a 100mL beaker, use a 100mL graduated cylinder to measure 20mL of concentrated hydrochloric acid into the beaker and immerse the foamed nickel, and let stand for 5min , it was observed that bubbles were generated on the surface of the foamed nickel, and the foamed nickel was taken out and rinsed 3 times with deionized water, then rinsed 3 times with absolute ethanol, blotted the ethanol on the surface with filter paper, and placed the foamed nickel in a beaker at an angle of 80 Dry at ℃ for 6h;

[0058] s12, preparation of Ni(OH) 2 / NF: Weigh 2.5g of nickel acetate, 0.7g of ammonium fluoride, and 3.2g of urea in a 100mL beak...

Embodiment 2

[0081] Embodiment 2: Fixed-point interception processing mode

[0082] This treatment mode is suitable for places that regularly produce wastewater containing heavy metals, such as electroplating factories, leather factories, mechanical processing and other places. Such as Figure 5 As shown, the NiO / NF active electrode is connected to the positive electrode of the external power supply, the graphite sheet is connected to the negative electrode of the external power supply, and a block is installed around the electrode, the waste water enters the treatment pool from the upper water inlet, the power is turned on, and the anode starts to electrolyze to produce flocculant, and the heavy metal Ion complexation precipitation, the generated sludge is blocked and filtered, recovered in time, and the water quality is detected in real time by the water quality detection device. When the water standard is met, the water outlet is opened, the water is discharged, and then the waste water...

Embodiment 3

[0083] Embodiment 3: intelligent robot processing mode

[0084] This treatment mode is suitable for waters seriously polluted by heavy metals. Such as Image 6 As shown, the electrode is installed on the bottom of the ship, the power supply is installed inside the ship, and a block is installed around the electrode. When the ship enters a heavily polluted water area, the power is turned on to start removal, and the generated sludge is filtered and recycled by the block to prevent it from entering the water body. , and monitor the water quality in real time, and when it reaches the water use standard, it can be driven and transferred to another heavily polluted water area, thereby achieving selective and fixed-point treatment, with high mobility and flexibility.

[0085] The above-mentioned treatment device of the present invention integrates multiple steps of electrolysis, flocculation, precipitation, sludge recovery, water quality detection, and remote control transfer, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com