Silver nanowire composite material, and preparation method and application thereof

A technology of nano-silver wire and composite material, applied in the field of antibacterial materials, can solve the problems of larger size of silver particles and weakened sterilization and disinfection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the preparation method of the nano-silver wire composite material provided by the present invention, the solvent is selected from one or more combinations of water, alcohols, ketones, ethers, lipids and other commonly used organic solvents.

[0033] Wherein, water is pure water.

[0034] Alcohols are selected from one or more combinations of methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol and the like.

[0035] The ketones are selected from one or more combinations of acetone, methyl butanone, methyl isobutyl ketone and the like.

[0036] The ethers are selected from one or more combinations of diethyl ether, ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, ethylene glycol monobutyl ether, and the like.

[0037] Lipids are selected from methyl acetate, ethyl acetate, propyl acetate and other commonly used organic solvents are selected from benzene, toluene, xylene, pentane, hexane, octane, cyclohexane, cyclohexanone, toluene cyclo...

Embodiment 1

[0064] Embodiment 1 (nano-silver wire composite material 1 preparation and antibacterial effect verification)

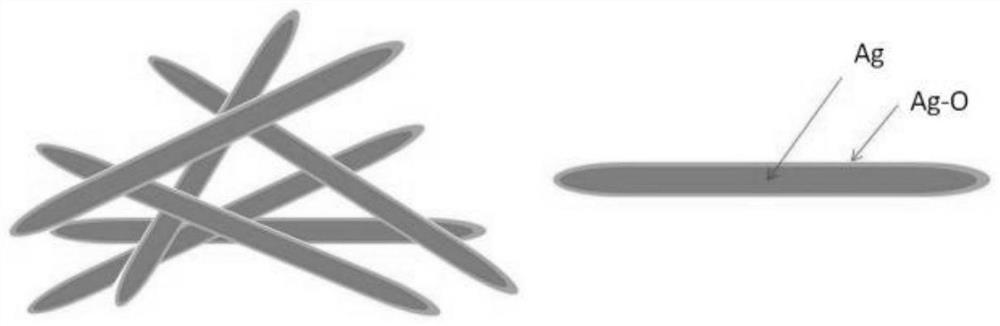

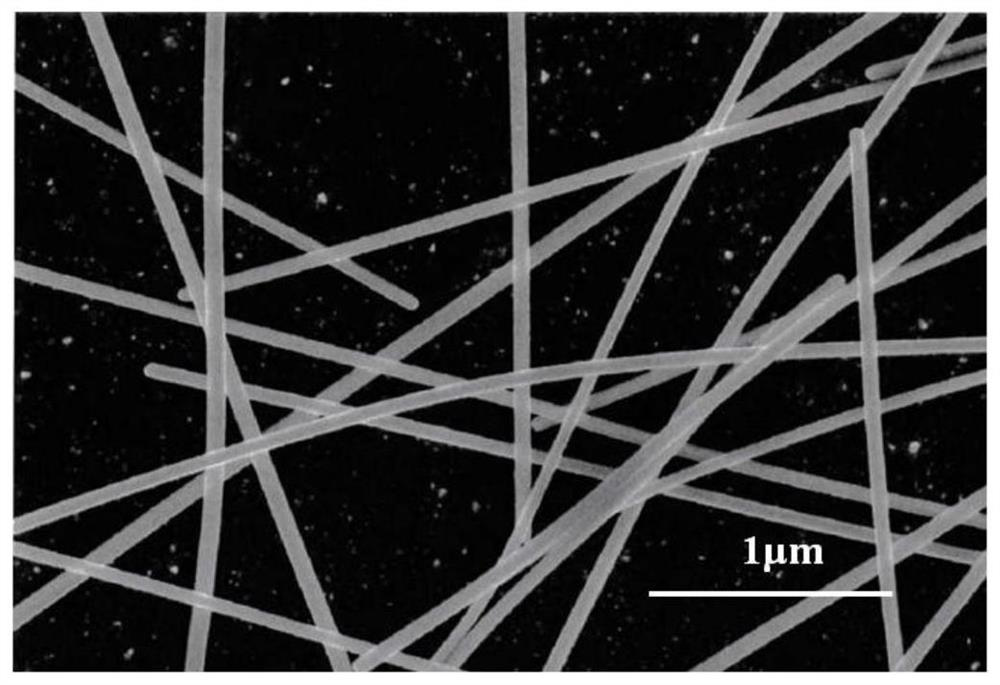

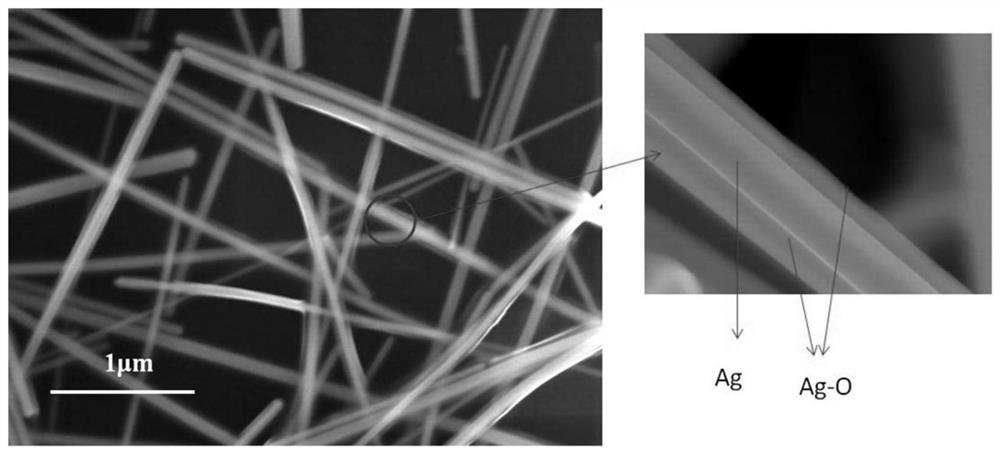

[0065] Preparation of silver nanowires: In a 250ml flask, put 100ml of ethylene glycol and 3g of polyvinylpyrrolidone (PVP K60) with a molecular weight of about 360,000, and place it in an oil bath at 140°C with stirring to dissolve completely. After adding 1 g of silver nitrate (AgNO 3 ) to dissolve completely. Continue to add 0.0036g of KBr and 0.0129g of AgCl as nucleating agents, continue to stir for 1 hour, then set the temperature to 150°C and continue to react for 1 hour. The obtained solution was centrifuged, washed with acetone and pure water, and dried to obtain a powder. The powder was subjected to scanning electron microscopy and the results were as follows: figure 2 shown. From figure 2 It can be seen that the synthesized basically pure silver nanowires.

[0066] Weighing 6 mg of nano silver wires was put into 200 g of ozone water with an ozone c...

Embodiment 2

[0070] Embodiment 2 (nano-silver wire composite material 2 preparation and antibacterial effect verification)

[0071] Preparation of silver nanowires: In a 250ml flask, put 100ml of ethylene glycol and 3g of polyvinylpyrrolidone (PVP K60) with a molecular weight of about 360,000, and place it in an oil bath at 140°C with stirring to dissolve completely. After adding 1 g of silver nitrate (AgNO 3 ) to dissolve completely. Continue to add 0.0036g of KBr and 0.0129g of AgCl as nucleating agents, continue to stir for 1 hour, then set the temperature to 150°C and continue to react for 1 hour. The obtained solution was centrifuged, washed with acetone and pure water, and dried to obtain a powder. The powder was subjected to scanning electron microscopy and the results were as follows: figure 2 shown. From figure 2 It can be seen that the synthesized basically pure silver nanowires.

[0072] The nano-silver wire of 3mg is weighed and added into the hydrogen peroxide solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com