A kind of treatment method of hypophosphite in electroless nickel plating waste liquid

A hypophosphite and treatment method technology, applied in chemical instruments and methods, metallurgical wastewater treatment, neutralization water/sewage treatment, etc., can solve the problems of non-selective oxidation, incomplete oxidation, high treatment cost, etc., and achieve a high degree of selectivity High efficiency, low treatment cost, and high oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

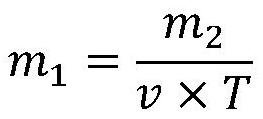

Embodiment 1

[0053] The influent water is electroless nickel plating waste liquid from an electroplating sewage treatment plant in Zhejiang. The waste liquid water enters this process section after being treated by an ultrafiltration membrane. The flow rate of the waste liquid is 10m 3 / d, the concentration of hypophosphite (in P) in the waste liquid is 500mg / L, and the pH value is 4.5. The pH value of the waste liquid was adjusted to 1.7 with hydrochloric acid, and then mixed with hydrogen peroxide (the amount of hydrogen peroxide added was 12 mL / L) to obtain pretreated wastewater. Through the formula of the above-mentioned activated carbon column preparation method and the relationship between each other, the amount of iodine adsorbed by activated carbon is 0.07g iodine element / g activated carbon. Two groups of activated carbon columns operate in parallel, and each group is connected in series by four activated carbon columns. The inner diameter of the activated carbon column is 390mm, h...

Embodiment 2

[0056] The influent water is electroless nickel plating waste liquid from an electroplating sewage treatment plant in Zhejiang. The waste liquid water enters this process section after being treated by an ultrafiltration membrane. The flow rate of the waste liquid is 10m 3 / d, the concentration of hypophosphite (in P) in the waste liquid is 500mg / L, and the pH value is 4.5. The waste liquid was adjusted to a pH value of 1.6 with hydrochloric acid, and then mixed with hydrogen peroxide (the amount of hydrogen peroxide added was 12 mL / L) to obtain pretreated wastewater. The amount of iodine pretreatment adsorbed by activated carbon is 0.07g iodine element / g activated carbon. There are two groups of activated carbon columns running in parallel. Each group consists of four activated carbon columns connected in series. Up-out method, each group of water flow 0.5m 3 / h.

[0057] Pass the pretreated wastewater into the activated carbon column treatment unit for post-treatment for 1...

Embodiment 3

[0059] The influent water is electroless nickel plating waste liquid from an electroplating sewage treatment plant in Zhejiang. The waste liquid water enters this process section after being treated by an ultrafiltration membrane. The flow rate of the waste liquid is 10m 3 / d, the concentration of hypophosphite (in P) in the waste liquid is 500mg / L, and the pH value is 4.5. The pH value of the waste liquid was adjusted to 1.8 with hydrochloric acid, and then mixed with hydrogen peroxide (the amount of hydrogen peroxide added was 12 mL / L)) to obtain pretreated wastewater. The amount of iodine pretreatment adsorbed by activated carbon is 0.07g iodine element / g activated carbon. There are two groups of activated carbon columns running in parallel. Each group consists of four activated carbon columns connected in series. Up-out method, each group of water flow 0.5m 3 / h.

[0060] Pass the pretreated wastewater into the activated carbon column treatment unit for post-treatment fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com