Perovskite compositions comprising mixed solvent systems

A technology of mixed solvent system and composition, which is applied in the fields of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc. It can solve high defect density, low crystallinity, reduce the efficiency and stability of perovskite solar cells, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0225]material

[0226]Unless otherwise stated, all chemicals were purchased from Sigma Aldrich and used without further purification. Methylammonium iodide was purchased from Greatcell Solar. The methyl ammonium hypophosphite was synthesized according to the procedure proven by Xiao et al. (Energy & Environmental Science (Energy & Environmental Science) 9, 867-872 (2016)).

[0227]Device characteristics

[0228]The J-V measurement of the perovskite module was performed with a Keithley 2400 source meter under simulated AM 1.5G radiation generated by a xenon lamp-based solar simulator (Sol3A, AAA solar simulator). A silicon reference cell (Newport 91150V-KG5) was used to calibrate the light intensity. The scan rate of the module is 1V / s and there is no pre-adjustment before measurement. To measure the long-term operational stability of the perovskite module, the module was encapsulated, illuminated by a daylight equivalent metal halide lamp, and loaded at the maximum power point. To measure t...

example 1

[0229]Example 1: Solvent engineering for perovskite ink solution

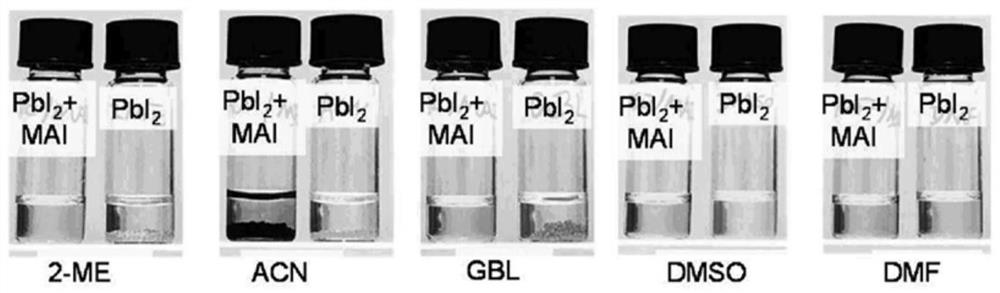

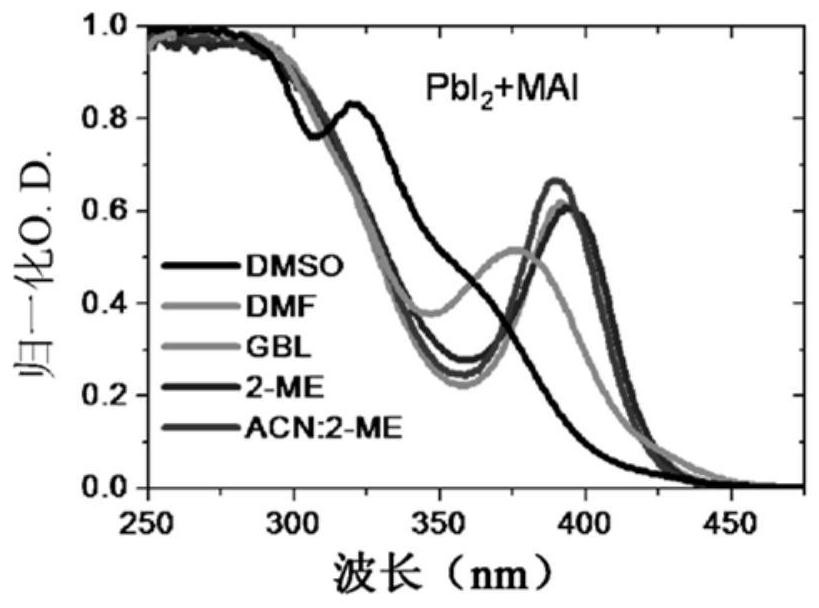

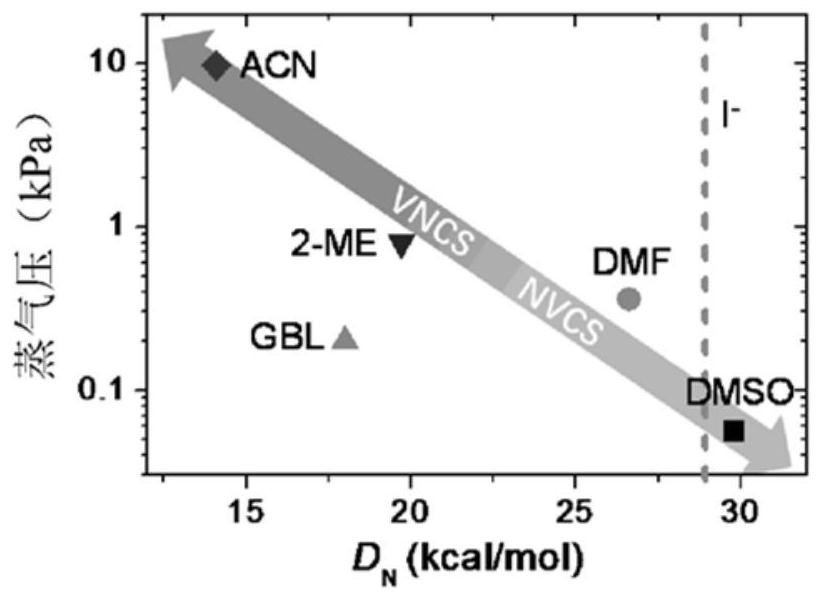

[0230]First study dimethyl sulfoxide (DMSO), dimethyl formamide (DMF), γ-butyrolactone (GBL), 2-methoxyethanol (2-ME), acetonitrile (ACN) and MAPbI3The coordination ability.10,11Found that DMSO and DMF are related to Pb2+Strong coordination of ions can dissolve PbI2,12However, GBL, 2-ME and ACN cannot dissolve PbI2, Unless you add MAI(Figure 1A ). It should be understood that only after MAI is dissolved, PbI2To pass PbI3-The formation of the complex is through I-Coordination to Pb2+Ion, for GBL, 2-ME and ACN:2-ME solutions, PbI is observed3-The characteristic absorption peak of the complex at 390nm (Figure 1B ).12,13In contrast, much weaker PbI is observed in DMF and DMSO-based solutions3-absorb. Instead of applying ACN only, use ACN:2-ME mixed solvent, because MAPbI should be understood3The solubility in ACN is much lower than that in other solvents (2+It has strong coordination ability, but GBL, 2-ME and ACN:2-ME do ...

example 2

[0231]Example 2: Use N 2 Knife Checking the Influence of Solvent on the Crystallinity of Perovskite

[0232]Then studied the room temperature N of the perovskite film using VNCS, NVCS or a combination of the two2Auxiliary doctor blade coating (Figure 3A withFigure 3D ). The membrane coated with 2-ME or ACN:2-ME (3:2 volume ratio) turns black immediately after coating, showing a pure perovskite phase, as passedFigure 4A withFigure 4C As evidenced by the X-ray diffraction pattern (XRD). In contrast, when DMSO or DMF is used as a solvent, the film remains wet and requires tens of minutes to dry at room temperature. Due to the strong coordination of DMSO or DMF with the perovskite precursor ink material, these films show a strong XRD peak of the mesophase below 10°. It should be noted that the drying of GBL-based solutions is also slow, but due to its low coordination capacity for GBL (such as the coordination capacity of 2-ME and ACN), the freshly dried membrane only exhibits a pure perov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com