A modified lignin weather-resistant adhesive and preparation method thereof

A lignin and adhesive technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of adhesives such as poor high temperature resistance, complicated preparation process, single component, etc., to achieve improved performance, The effect of reducing cost and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

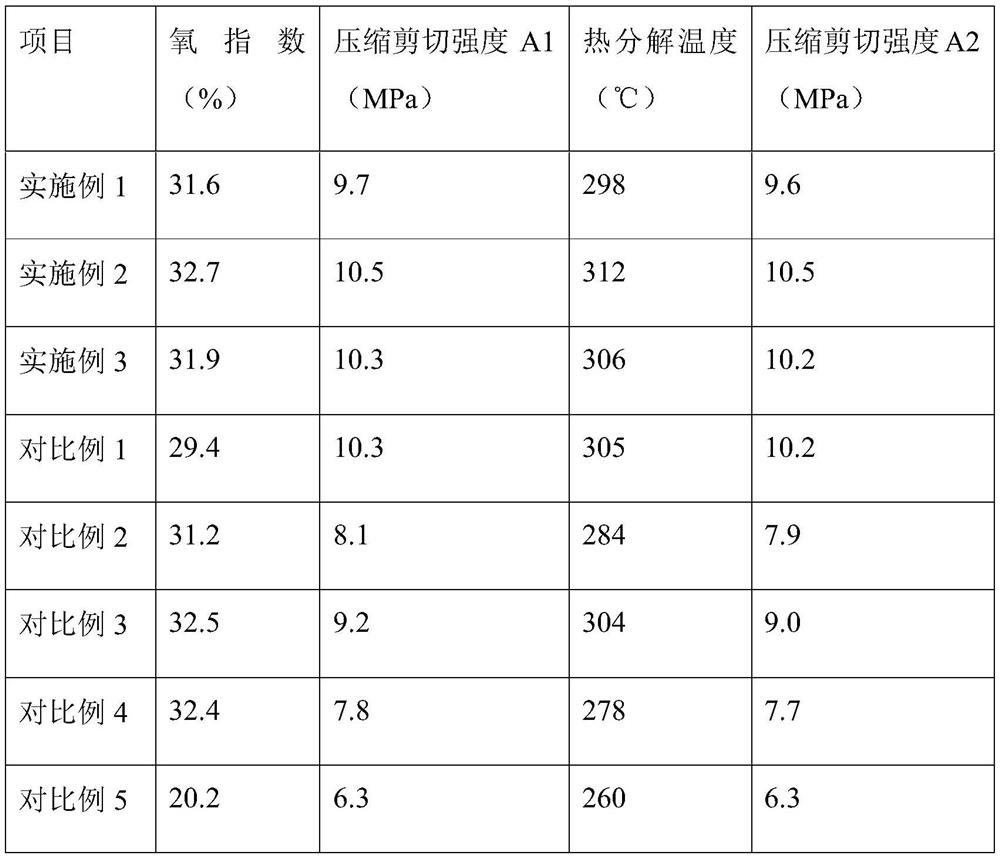

Examples

Embodiment 1

[0036] A preparation method of a modified lignin weather-resistant adhesive, comprising the following steps:

[0037] (1) Take acidic lignin, dry at 60°C for 18 hours, ball mill for 5 minutes, add resorcinol and acetone, mix and stir for 20 minutes, remove acetone by rotary evaporation, add concentrated sulfuric acid, stir for 1 hour, filter, deionized water Wash until neutral, dry to obtain phenolized lignin;

[0038] (2) Take defatted soybean protein powder and water, mix and stir at 38°C for 20 minutes, add sodium hydroxide, adjust the pH to 9, continue to stir and react for 1 hour, then add additives, stir and react until the pH is 8, then add phenolized lignin , alkaline lignin, phenol and formaldehyde, heat preservation reaction at 75°C for 50 minutes, add hydrogen peroxide, continue to stir and react for 20 minutes, and obtain material A;

[0039] (3) Take material A, slowly cool down to 68°C, continue to add formaldehyde and sodium hydroxide, continue to react for 20 ...

Embodiment 2

[0045] A preparation method of a modified lignin weather-resistant adhesive, comprising the following steps:

[0046] (1) Take acidic lignin, dry at 65°C for 19 hours, ball mill for 8 minutes, add resorcinol and acetone, mix and stir for 25 minutes, remove acetone by rotary evaporation, add concentrated sulfuric acid, stir for 1.2 hours, filter and deionize Washing with water until neutral, drying to obtain phenolated lignin;

[0047] (2) Take defatted soybean protein powder and water, mix and stir at 39°C for 25 minutes, add sodium hydroxide, adjust the pH to 9.5, continue to stir and react for 1.1 hours, then add additives, stir and react until the pH is 8.5, and then add phenolized lignin lignin, alkaline lignin, phenol and formaldehyde, heat preservation reaction at 78°C for 55 minutes, add hydrogen peroxide, continue to stir and react for 25 minutes, and obtain material A;

[0048] (3) Take material A, slowly cool down to 70°C, continue to add formaldehyde and sodium hyd...

Embodiment 3

[0054] A preparation method of a modified lignin weather-resistant adhesive, comprising the following steps:

[0055] (1) Take acidic lignin, dry at 70°C for 20 hours, ball mill for 10 minutes, add resorcinol and acetone, mix and stir for 30 minutes, remove acetone by rotary evaporation, add concentrated sulfuric acid, stir for 1.5 hours, filter and deionize Washing with water until neutral, drying to obtain phenolated lignin;

[0056] (2) Take defatted soy protein powder and water, mix and stir for 30 minutes at 38-40°C, add sodium hydroxide, adjust the pH to 10, continue to stir and react for 1.2 hours, then add additives, stir and react until the pH is 8.5, and then add phenol Chemical lignin, alkaline lignin, phenol and formaldehyde, heat preservation reaction at 80°C for 60 minutes, add hydrogen peroxide, continue stirring and reaction for 30 minutes, and obtain material A;

[0057] (3) Take material A, slowly lower the temperature to 72°C, continue to add formaldehyde a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com