A kind of layered siox material and its preparation method and application

A layered, adjacent layer technology, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve the problem of no silicon oxide report, and achieve efficient and easy preparation methods, simple operation steps, and excellent electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation method of layered SiOx material of the present embodiment, specific preparation steps are as follows:

[0048] (1) 2g CaSi 2 Slowly add 200ml of NaCl solution with a concentration of 10mol / L, and add 200ml of CH with a concentration of 8mol / L at a rate of 1ml / min at a stirring speed of 800r / min. 3 COOH, stirred for 3 days, sonicated at 80W for 1 hour, washed with deionized water for 4 times until the filtrate was neutral, and freeze-dried for 12 hours to obtain a green layered siloxene material;

[0049] (2) Weigh 1 g of siloxene material and heat it up to 400 °C at a rate of 5 °C / min in a tube furnace in an Ar atmosphere and keep it for 1 h. After cooling down to room temperature naturally, the layered SiOx material can be obtained.

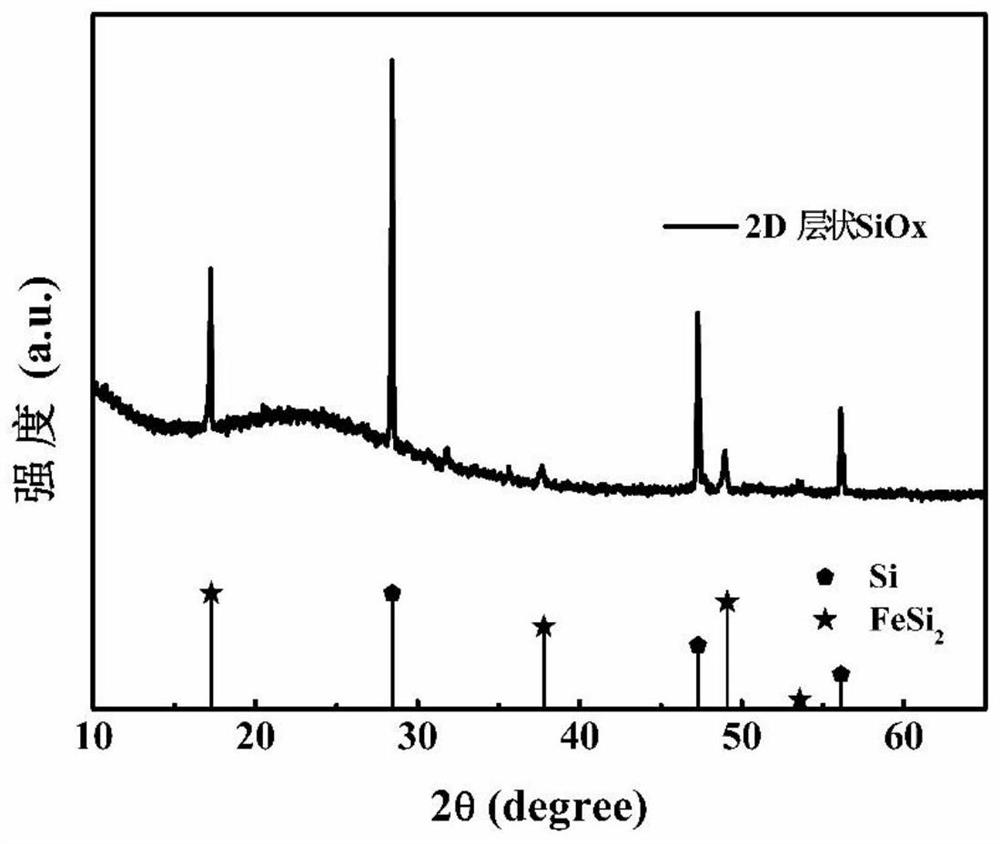

[0050] The layered SiO material that the embodiment of the present invention 1 obtains is detected as follows below:

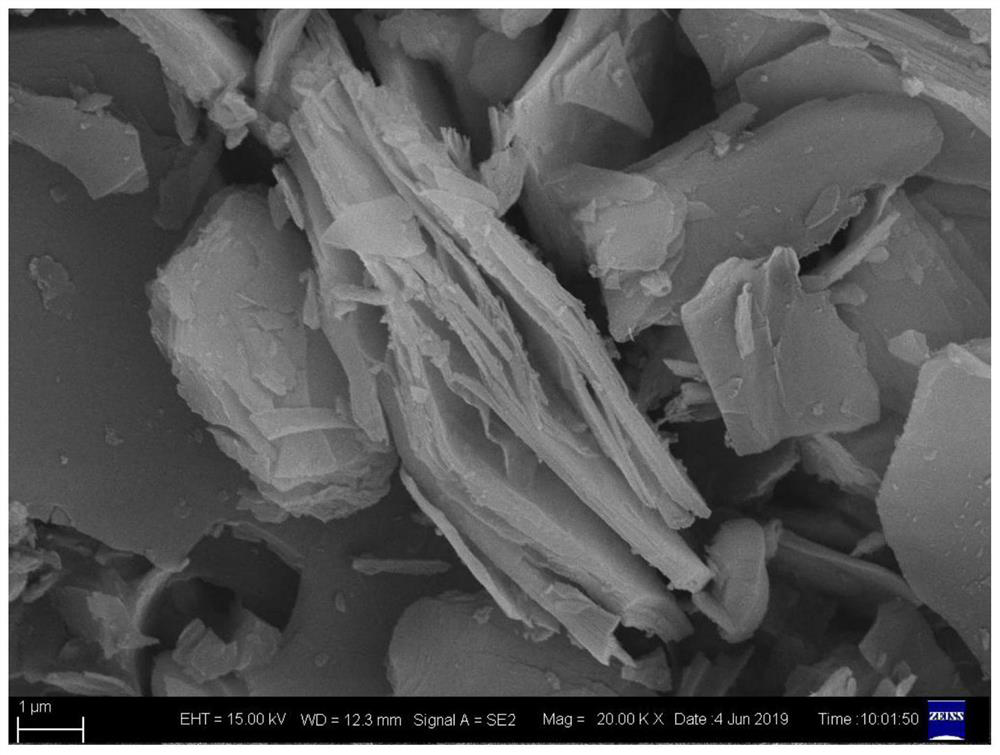

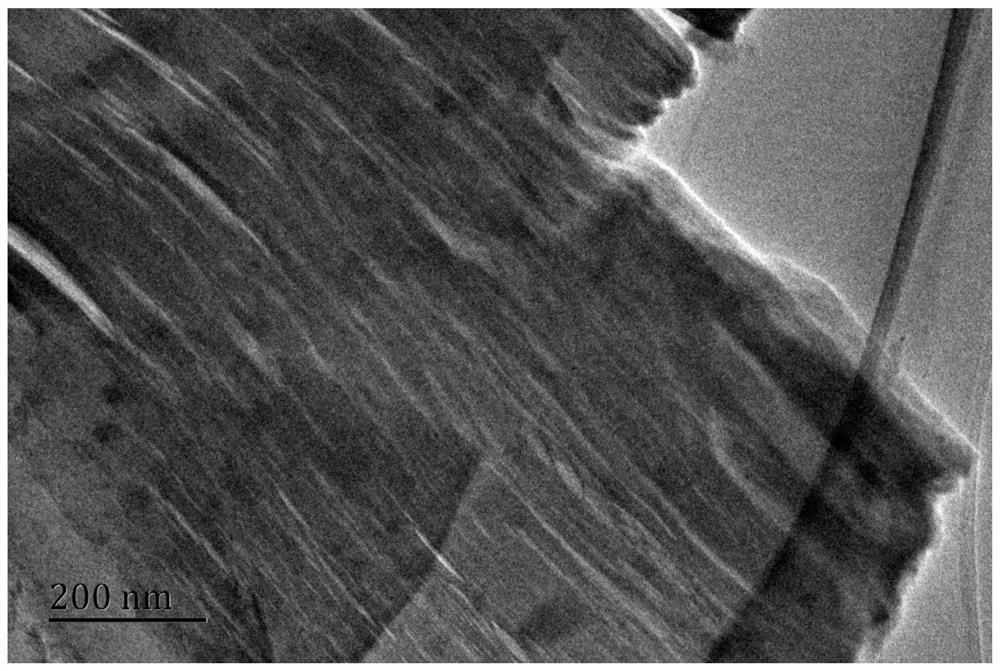

[0051] The SEM image of the layered SiOx material prepared in Example 1 of the present inventio...

Embodiment 2

[0063] A kind of preparation method of layered SiOx material of the present embodiment, specific preparation steps are as follows:

[0064] (1) 10g CaSi 2 Slowly add 500ml of AlCl with a concentration of 10mol / L 3 In the solution, add 1000ml of HNO with a concentration of 10mol / L at a rate of 2ml / min at a stirring speed of 1000r / min 3 , stirred and reacted for 4 days, sonicated at 80W for 2 hours, washed with deionized water for 4 times until the filtrate was neutral, and freeze-dried at -45°C for 12 hours to obtain a siloxene material;

[0065] (2) Weigh 5g of siloxene material and heat it up to 300°C at a rate of 2°C / min in a tube furnace under an Ar atmosphere and hold it for 2h. After cooling down to room temperature naturally, a layered SiOx material can be obtained.

[0066] The material that embodiment 2 obtains is carried out scanning electron microscope test, and result is as follows Figure 8 As shown, the SiOx material has a layered structure with a large number ...

Embodiment 3

[0068] A kind of preparation method of layered SiOx material of the present embodiment, specific preparation steps are as follows:

[0069] (1) 20g CaSi 2 Slowly add 400ml of NaCl solution with a concentration of 15mol / L, and add 500ml of CH with a concentration of 12mol / L at a rate of 0.5ml / min at a stirring speed of 500r / min. 3 CH 2 COOH, stirred for 4 days, sonicated at 100W for 3 hours, washed with deionized water for 4 times until the filtrate was neutral, and vacuum-dried at 100°C for 12 hours to obtain a siloxene material;

[0070] (2) Put the siloxene material in the tube furnace under H 2 Under the / Ar mixed atmosphere, the temperature was raised to 450 °C at a rate of 5 °C / min and kept for 1 h, and the SiOx material was obtained after cooling down to room temperature naturally.

[0071] The material that embodiment 3 obtains is carried out scanning electron microscope test, and result is as follows Figure 11 As shown, the SiOx material presents an accordion-like...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com