A kind of method that cyclopentene prepares cyclopentyl alcohol through cyclopentyl formate

A technology of cyclopentene and cyclopentanol, which is applied in the field of cyclopentene to cyclopentyl formate to prepare cyclopentyl alcohol, can solve the problems of product separation and purification difficulties, environmental pollution, etc., to reduce the difficulty of separation, simplify the process flow, and transform high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

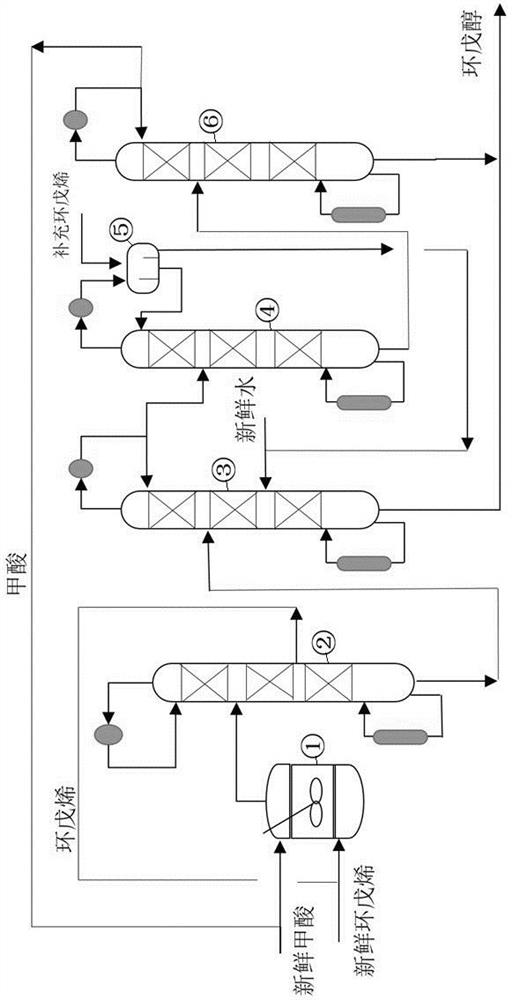

Image

Examples

Embodiment 1

[0045] 3700kg / hr cyclopentene and 9312 kg / hr cyclopentene returned from the side mining of the subsequent olefin esterification tower are mixed and sent to the reactor. A total of 2845kg / hr of fresh formic acid and the formic acid returned from the formic acid recovery tower are also sent into the reactor. The reaction temperature of the reactor is 90°C, the reaction pressure is 0.4Mpa, the residence time of the materials in the reactor is 120min, and the molar ratio of cyclopentene to formic acid is 3.5.

[0046] The number of theoretical plates from the upper feed port to the top of the olefin esterification tower is 10, the number of theoretical plates between the feed port and the liquid side sampling port is 10, and the theoretical plate number from the liquid phase side sampling port to the tower kettle is 10. Count to 15. The ratio of reflux to feed at the top of the olefin esterification tower is 4, the temperature at the top of the tower is 85°C, the bottom of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com