System and method for realizing aluminum ash resource utilization by plasma technology

A plasma and resource-based technology, applied in the purification of alumina/aluminum hydroxide, aluminate/alumina/aluminum hydroxide, energy input, etc., can solve the problems of complex process and difficult industrial application, and achieve simple process, Avoid secondary environmental pollution, good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical solution, implementation method, purpose and effect of the present invention in detail, further description will be made below in conjunction with the embodiments and accompanying drawings.

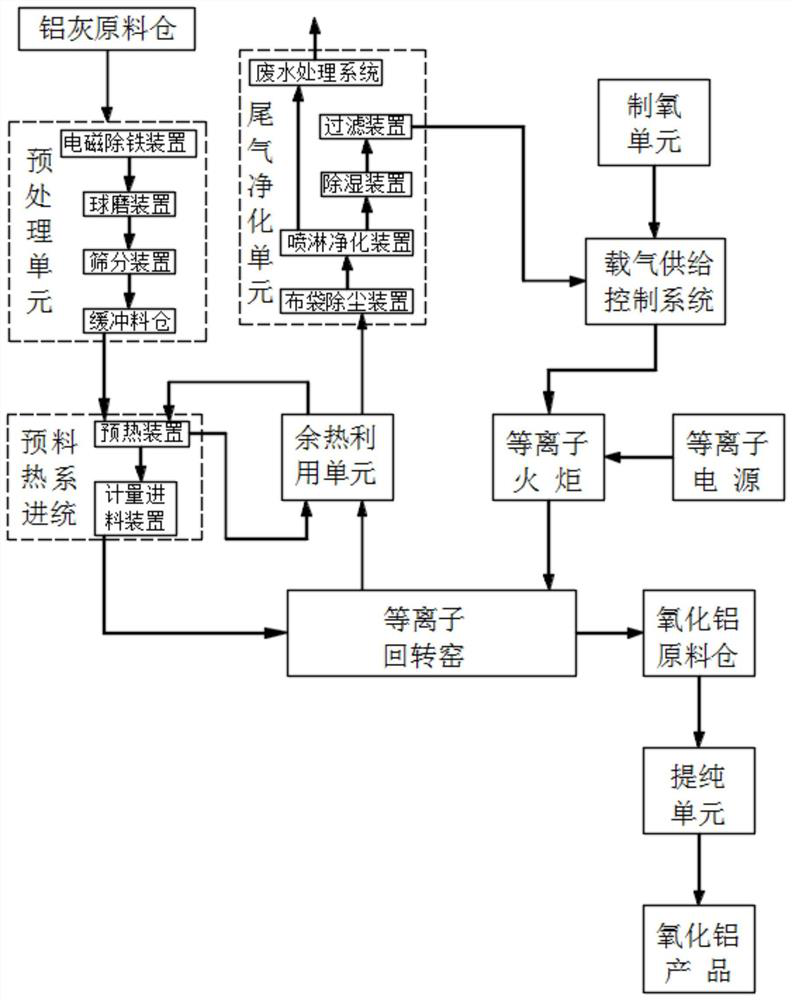

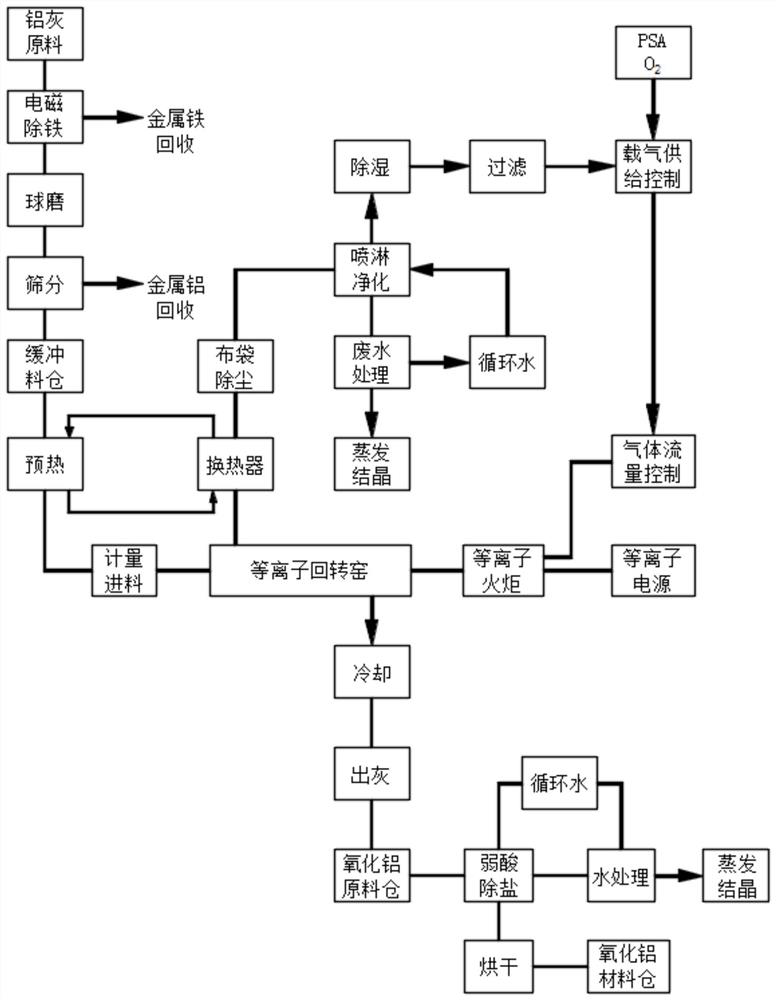

[0027] see figure 1 and figure 2 , gives a structural schematic diagram and a detailed process flow chart of the system and method for realizing resource utilization of aluminum ash by plasma technology in this example.

[0028] It can be seen from the figure that the plasma technology provided in this example realizes the resource utilization of aluminum ash. Firstly, the aluminum ash raw material to be processed is placed in the aluminum ash raw material warehouse, and the aluminum ash raw material is sent to the electromagnetic iron removal device by the feeding device for electromagnetic iron removal. After the iron-containing magnetic substances contained in the aluminum ash are removed to a certain extent, the raw materials after iron remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com