Camellia oleosa seed oil soap base material and preparation method thereof

A technology of camellia seed oil and soap base, which is applied in the field of camellia oil soap base material and preparation thereof, can solve the problems of poor skin experience, shortened reaction time, incomplete reaction and the like of soap, and achieves short reaction time and low reaction temperature. , the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

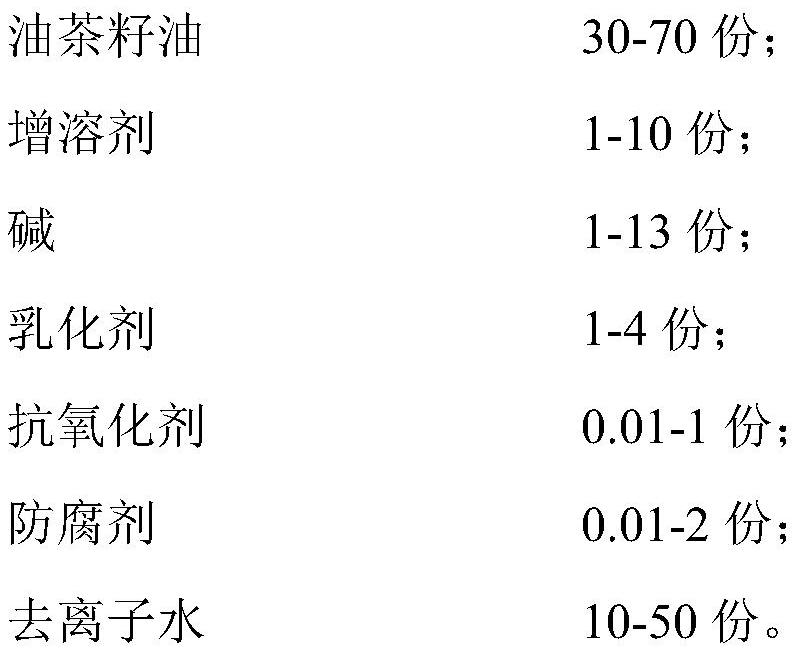

Method used

Image

Examples

Embodiment 1

[0038] (1) Boil the deionized water, after cooling, dissolve 4 parts of potassium hydroxide and 2 parts of triethanolamine in 47.99 parts of deionized water to obtain a compounded lye;

[0039] (2) Add 40 parts of Camellia oleifera seed oil and 3 parts of alkyl polyglucoside into the saponification pot, stir at a speed of 500r / min, after 10mins, add the lye compounded in step (1) into the saponification pot, After 30mins, heat up to 50°C at a rate of 5°C / min and keep it constant;

[0040] (3) After 45mins, add 0.01 part of phytic acid;

[0041] (4) After 5 minutes, stop stirring, replace the stirring and dispersing disk with an emulsifying disk, add 2 parts of sucrose fatty acid ester and 1 part of methyl p-hydroxybenzoate into the saponification pot, and emulsify for 10 minutes, stop heating and stir to room temperature;

[0042] (5) Obtain light yellow camellia oleifera seed oil soap base material, its viscosity is 7000mPa·s, and the measured pH value of 10% camellia oleif...

Embodiment 2

[0044] (1) Boil the deionized water, after cooling, dissolve 4 parts of potassium hydroxide and 2 parts of triethanolamine in 47.99 parts of deionized water to obtain a compounded lye;

[0045](2) Add 40 parts of Camellia oleifera seed oil and 3 parts of butanediol into the saponification pot, stir at a speed of 500r / min, after 10mins, add the lye compounded in step (1) into the saponification pot, after 25mins , the temperature was raised to 50°C at a rate of 5°C / min and kept constant;

[0046] (3) After 40mins, add 0.01 parts of phytic acid;

[0047] (4) After 5 minutes, stop stirring, replace the stirring and dispersing disk with an emulsifying disk, add 2 parts of sucrose fatty acid ester and 1 part of methyl p-hydroxybenzoate into the saponification pot, and emulsify for 10 minutes, stop heating and stir to room temperature;

[0048] (5) A light yellow camellia oleifera seed oil soap-based material was obtained, the viscosity of which was 7500 mPa·s, and the measured pH...

Embodiment 3

[0050] (1) Boil the deionized water, after cooling, dissolve 4 parts of potassium hydroxide and 2 parts of triethanolamine in 47.99 parts of deionized water to obtain a compounded lye;

[0051] (2) Add 40 parts of camellia seed oil and 3 parts of polyethylene glycol fatty ether into the saponification pot, stir at a speed of 500r / min, and after 10mins, add the lye compounded in step (1) into the saponification pot , after 30mins, the temperature was raised to 50°C at a rate of 5°C / min and kept constant;

[0052] (3) After 30mins, add 0.01 parts of phytic acid;

[0053] (4) After 5 minutes, stop stirring, replace the stirring and dispersing disk with an emulsifying disk, add 2 parts of sucrose fatty acid ester and 1 part of methyl p-hydroxybenzoate into the saponification pot, and emulsify for 10 minutes, stop heating and stir to room temperature;

[0054] (5) A light yellow Camellia oleifera seed oil soap-based material was obtained, the viscosity of which was 6500 mPa·s, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com