Droplet-resistant flame-retardant modified polyester and preparation method thereof

A flame-retardant modified polyester and anti-melt drop technology, which is applied in the field of polyester, can solve the problems of increasing the amount of fluorine-based polymers, uneven dispersion, poor stability, etc., and achieve improved anti-melt drop performance and enhanced flame retardancy effect, the effect of improving droplet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

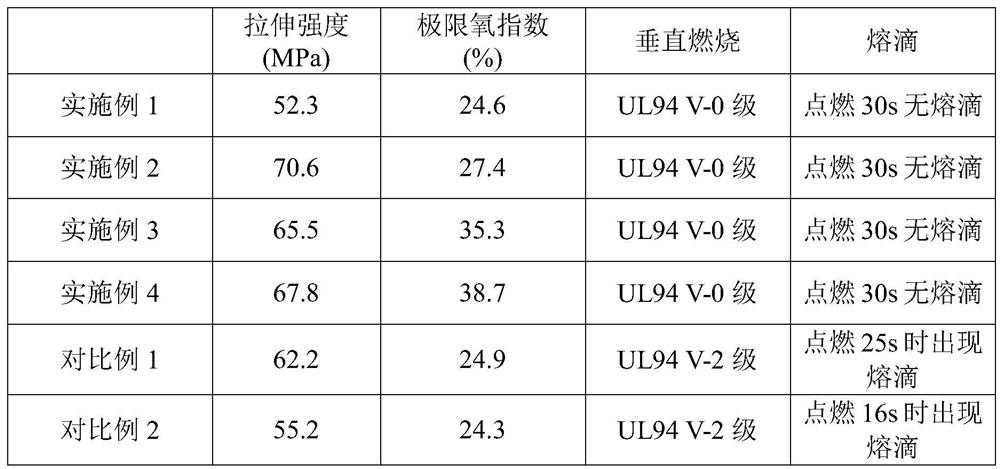

Examples

Embodiment 1

[0032]A kind of droplet-resistant flame-retardant modified polyester, including the following raw materials in parts by weight: 88 parts of polyethylene terephthalate resin, 10 parts of zinc diethyl hypophosphite, modified carboxyl group-containing polyester with a particle size of 100 μm 5 parts of polytetrafluoroethylene particles, 2 parts of lithium chloride.

[0033] The preparation method of the above-mentioned modified polytetrafluoroethylene particles containing carboxyl groups is as follows: metal sodium is added to the solution of tetrahydrofuran and naphthalene to prepare a mixed solution with a mass fraction of metal sodium of 5%; the mixed solution is stirred at room temperature for 2 h Finally, the color of the solution is dark brown or black; immerse the polytetrafluoroethylene powder in the solution for 10 minutes; take it out and soak it in acetone solution for 5 minutes, take it out of the acetone solution, rinse it with clean water, and put it in a dark place ...

Embodiment 2

[0037] A droplet-resistant flame-retardant modified polyester, comprising the following raw materials in parts by weight: 80 parts of polyethylene naphthalate resin, 15 parts of ammonium polyphosphate, and modified polyperfluorinated polyfluoride containing carboxyl groups with a particle size of 200 μm. 6 parts of ethylene propylene particles, 3 parts of calcium chloride.

[0038] The preparation method of the above-mentioned modified polyperfluoroethylene propylene particles containing carboxyl groups is as follows: 30L of water is added to a 50L reactor, and after vacuuming until the oxygen content is less than 30ppm, 35g of perfluorooctanoate is added and the temperature is raised to 80°C; the mass ratio of the addition is 5:1 of hexafluoropropylene and tetrafluoroethylene until the pressure in the reactor is 4.5MPa, then add 7g of potassium persulfate and 7.5g of ammonium persulfate; after 30min of reaction, add 0.4g of ammonium persulfate and 8g of dibutyl peroxide acid,...

Embodiment 3

[0042] A kind of droplet-resistant and flame-retardant modified polyester, including the following raw materials in parts by weight: 72 parts of polyethylene furandicarboxylate resin, 25 parts of triphenyl phosphate, and modified polytetrafluoroethylene with a particle size of 3 mm and containing carboxyl groups. 8 parts of vinyl fluoride particles, 5 parts of zinc chloride.

[0043] The preparation method of the above-mentioned modified polytetrafluoroethylene powder containing carboxyl groups is as follows: metal sodium is added to the solution of tetrahydrofuran and naphthalene to prepare a mixed solution with a mass fraction of metal sodium of 5%; the mixed solution is stirred at room temperature After 2 hours, the color of the solution is dark brown or black; immerse the polytetrafluoroethylene powder in the solution for 10 minutes; take it out and soak it in acetone solution for 5 minutes, take it out of the acetone solution, rinse it with clean water, and put it in a dar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com