Heating device, preparation method of device and high-temperature heating equipment

A technology of high-temperature heating equipment and heating device, applied in lighting and heating equipment, electric heating fuel, heating fuel, etc., can solve the problem that the thermal expansion coefficient of tungsten wire and silicon nitride is greatly different, and the original taste and nutrition of food cannot be maintained. The controllability of temperature is not strong and other problems, so as to ensure the safety of electricity consumption, high production efficiency and productivity, and good energy efficiency performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

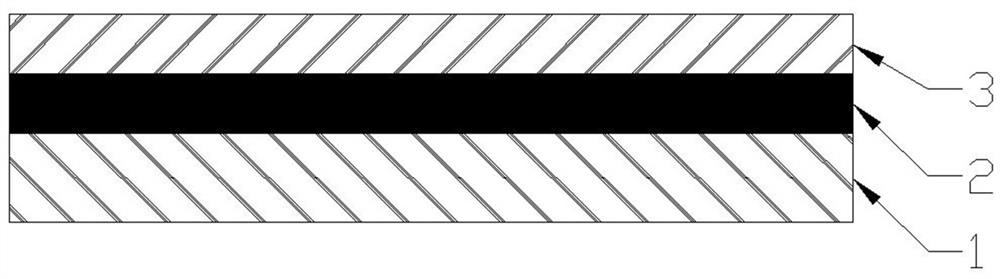

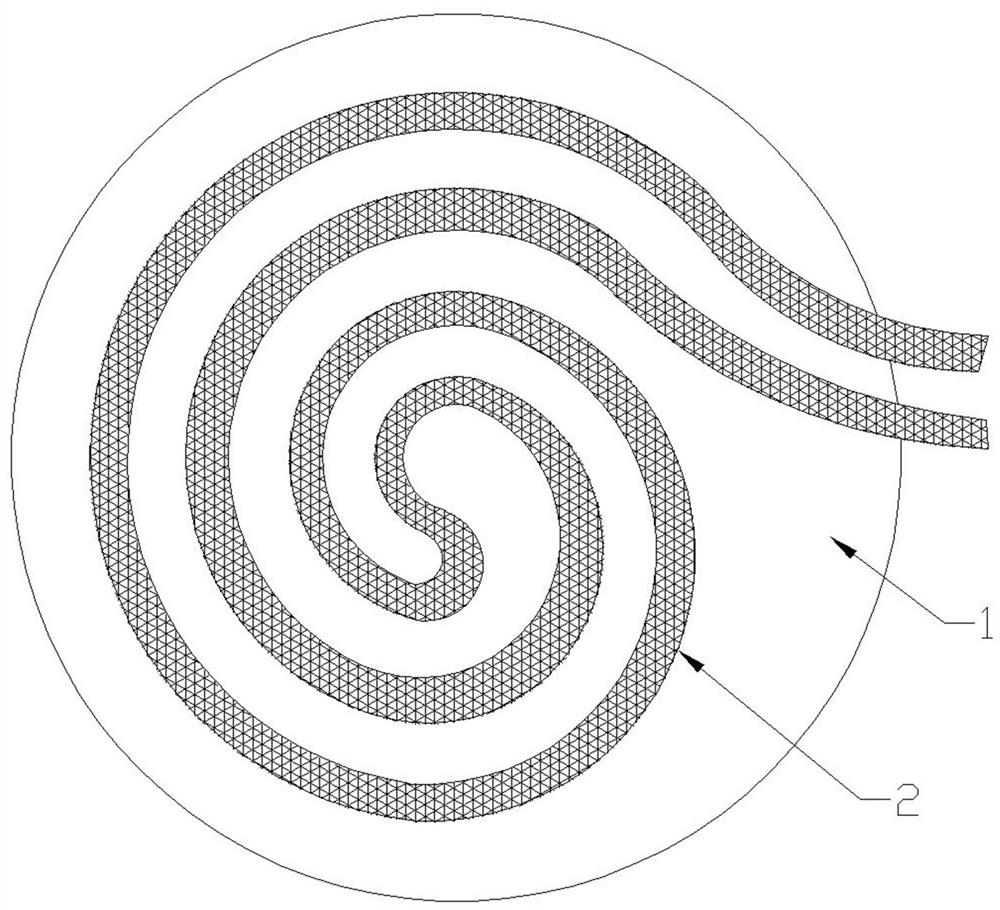

[0037] Such as figure 1 As shown, the heating device of the present invention includes an insulating base layer 1, a titanium diboride semiconductor film layer 2 is sputtered on one surface of the insulating base layer 1, and outside the titanium diboride semiconductor film layer 2 An anti-oxidation and insulating protective film layer 3 is sputtered. Specifically, the insulating base layer 1 is an alumina ceramic base layer. The anti-oxidation and insulating protective film layer 3 is an aluminum oxide film layer. The thickness range of the titanium diboride semiconductor film layer 2 is 0.1-10 µm, which can be set according to actual needs. The thickness of the insulating base layer 1 is 0.5-3 mm.

[0038] Here, the coefficient of thermal expansion of alumina is 7.85×10 -6 m / m.k, while the thermal expansion coefficient of titanium diboride is 8.1×10 -6 m / m.k, the thermal expansion coefficients of the two are very similar. When the two are combined as the materials of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com