A Method for Enhancing Molecular Planarity of Non-Screw Organic Small Molecule Hole Transport Materials

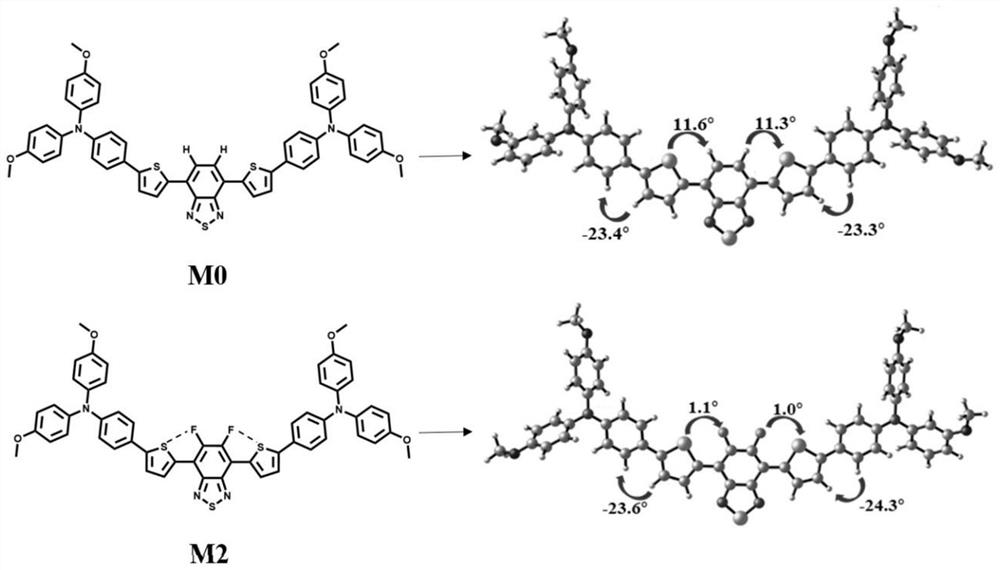

A hole transport material and small molecule technology, which is applied in the field of molecular planarity enhancement of non-spiro-type organic small molecule hole transport materials, can solve the problems of inability to achieve conjugation, increased manufacturing costs, high synthesis costs, etc. Hole mobility, enhanced molecular planarity, enhanced effect of π-π stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Synthesis of compound M0:

[0040]

[0041] Specific steps are as follows:

[0042] In a 50mL round-bottomed flask, an aqueous solution of compound 1 (458mg, 1mmol), 4-boronate-4', 4'-dimethoxytriphenylamine (1.08g, 2.5mmol), potassium carbonate ( 4M, 4mL), Pd(PPh 3 ) 4 (57 mg, 0.05 mmol), anhydrous DMF (20 mL) and absolute ethanol (4 mL). The reaction solution was stirred at 120° C. for 24 hours under nitrogen protection. After the reaction was cooled to room temperature, the reaction mixture was extracted with ethyl acetate and washed with saturated brine. The organic phase was dried with anhydrous magnesium sulfate and concentrated by rotary evaporation, and the obtained crude product was separated by column chromatography, using petroleum ether / dichloromethane (v / v=5 / 1) as eluent, and reacted to obtain 589 mg of a purple solid Product, yield 65%. 1H NMR (300MHz, CDCl 3 )δ8.10-8.09(d,2H), 7.84(s,2H), 7.51-7.48(d,4H), 7.28-7.27(d,2H), 7.10-7.06(m,8H), 6....

Embodiment 2

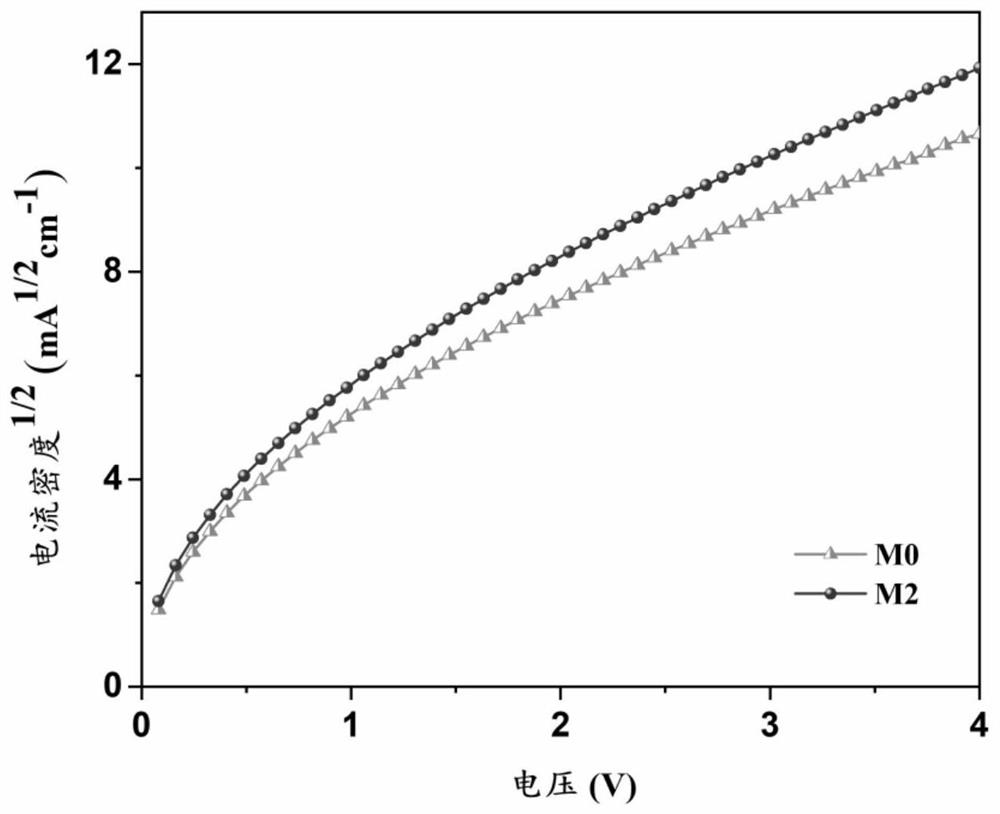

[0050] Compound M2 and compound M0 synthesized in Example 1 were used to prepare single-hole device FTO / PEDOT:PSS / HTM / Au respectively, and obtained by space-limited current method as follows: figure 2 J shown 1 / 2 – V-curve (SCLC) to estimate hole mobility. As a result, the hole mobility of M2 was calculated to be 1.33×10 -6 cm 2 V -1 the s -1 , the hole mobility of M0 is 8.92×10 -7 cm 2 V -1 the s -1 . It can be seen that the void mobility of compound M2 is significantly higher than that of compound M0.

Embodiment 3

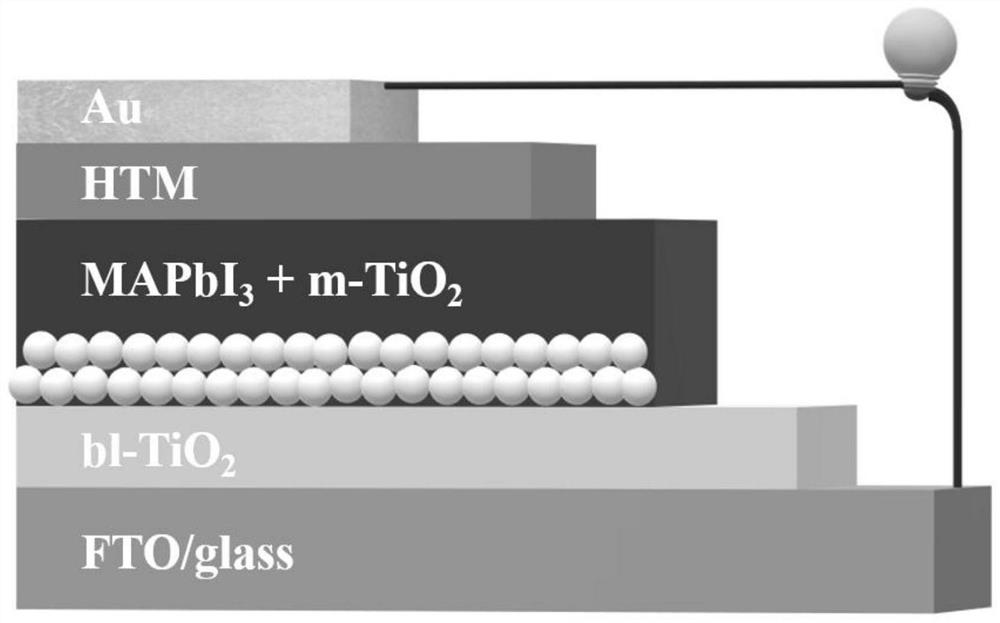

[0052] The compound M2 synthesized in Example 1 and its compound M0 are used as undoped hole transport materials in organic-inorganic perovskite solar cells, and their structure is: FTO / ETM / m-TiO 2 / MAPB 3 / HTM / Au, such as image 3 Shown; The compound M2 can be used as a hole transport material but not limited to this perovskite solar cell structure. The preparation process of perovskite solar cells is as follows: first, cut FTO conductive glass (15Ω / square, thickness 2.3mm) into small pieces of 1.5cm×2cm, and then use zinc powder and 2M hydrochloric acid to etch it according to the electrode pattern. After etching, the glass was ultrasonically cleaned with acetone and ethanol for ten minutes, dried with clean compressed air, and then annealed at 510°C for 30 minutes. Mix 7mL of isopropanol, 0.6mL of tetraisopropyl titanate and 0.4mL of acetone evenly, and then use nitrogen as the carrier gas to spray onto the FTO glass substrate heated at 450°C, heat for 20min and then cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com