Preparation method of bifidobacterium microcapsules based on endogenous emulsification

A technology of bifidobacteria and microcapsules, which is applied in the field of preparation of bifidobacteria microcapsules, can solve the problems of too large particle size and fixed-point release, and achieve the effect of less crack distribution, easy control and dense surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

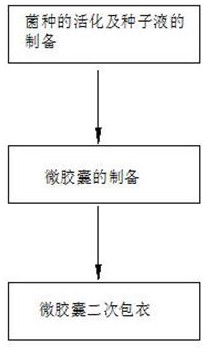

[0035] combine figure 1 , a preparation method based on endogenous emulsified bifidobacterium microcapsules, comprising the steps of:

[0036] S1. Activation of strains and preparation of seed solution: Subculture bifidobacteria stored at low temperature in 37°C constant temperature MRS liquid medium, and inoculate in MRS solid medium for 24 hours after dilution of the three-generation cultured bacteria solution. -48h, pick a single colony and inoculate it into the MRS liquid medium to activate the seed liquid of passage 2-3, centrifuge and wash it, and then obtain the concentrated bacterial liquid and store it at low temperature for later use;

[0037] S2. Preparation of microcapsules: use sodium alginate and calcium carbonate as wall materials, and bifidobacteria as capsule materials, activate the concentrated bacterial solution obtained in S1 for 2-3 generations and collect the bacteria sludge, and sterilize the sodium alginate Mix the solution, bacteria slime and calcium ...

Embodiment 2

[0040] On the basis of embodiment 1, a kind of preparation method based on the bifidobacterium microcapsule of endogenous emulsification is characterized in that: comprise the steps:

[0041] S1: Activation of strains and preparation of seed liquid: The bifidobacteria preserved at low temperature were subcultured in 37°C constant temperature MRS liquid medium, and the bacteria liquid after the third-generation culture was diluted and inoculated in MRS solid medium for 36 hours. , pick a single colony and inoculate it into the MRS liquid medium to activate the seed liquid of passage 2-3, centrifuge and wash it, and then obtain the concentrated bacterial liquid and store it at low temperature for later use;

[0042] Liquid MRS medium: peptone 10.0g, yeast extract 5.0g, glucose 20.0g, ethyl sodium 5.0g, beef 10.0g, Tween 80 1.0ml, diamine hydrogen citrate 2.0g, dipotassium hydrogen phosphate 2.0g, MgSO 4 ·7H 2 O 0.2g, MnSO 4 ·H 2 O 1.0g, distilled water 1000mL, pH6.2-6.4, ster...

Embodiment 3

[0052] On the basis of Example 2, the morphology observation of microcapsules and the analysis of particle size: get 1 drop of the dispersed solution of microcapsules with glass rod, place on glass slide, carry out morphology observation with optical microscope, measure with micrometer The particle diameter of the capsules, count more than 100, take the average value, put the prepared microcapsules into a vacuum freeze dryer after pre-freezing, take them out after 24h, measure the entrapment rate and The number of viable bacteria, the ratio of bacteria slime and protective agent is 1:2.5, the concentration of trehalose in the protective agent is 10%, the concentration of skim milk is 15%, the concentration of glycerin is 3%, and the concentration of L-cysteine is 2%, the embedding rate reaches the highest is 84.5%, and the number of live bacteria is at least 7.88×10 9 cfu / mL, the structure of microcapsules after freeze-drying was observed by scanning electron microscope.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com