Hydrolyzed protein liposome as well as preparation method and application thereof

A technology for hydrolyzing keratin and protein lipids, which can be used in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc. It can solve the problems of low concentration of hydrolyzed keratin, unstable active properties, surface denaturation, etc., and increase the concentration of active substances , Improve encapsulation efficiency, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

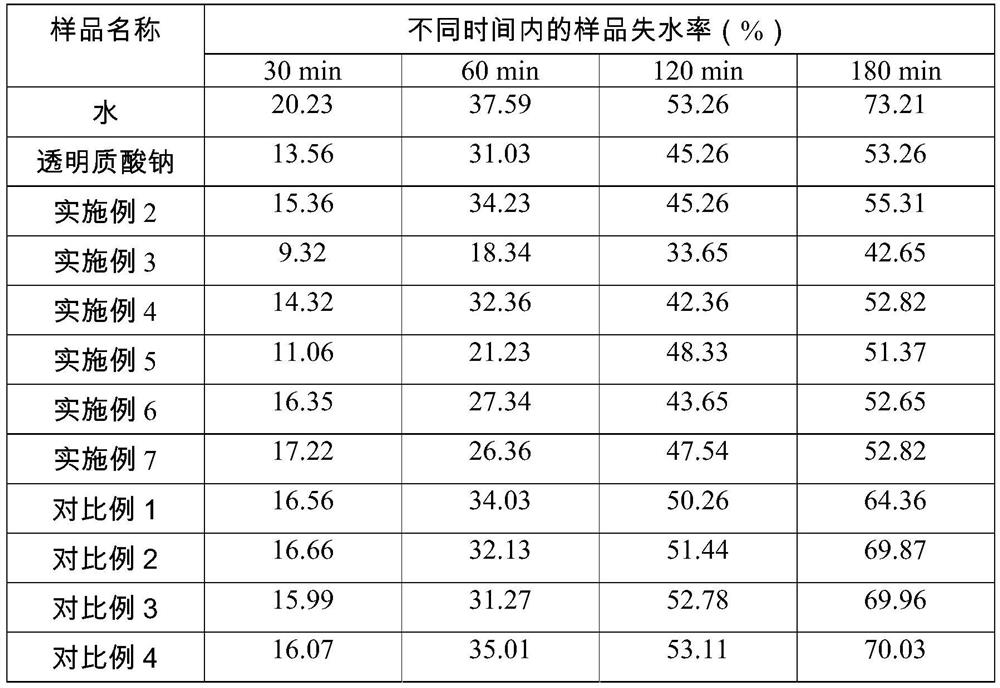

Examples

Embodiment 1

[0040] The preparation of embodiment 1 hydrolyzed keratin

[0041] The preparation of hydrolyzed keratin of the present invention comprises the following steps:

[0042] S1. Wash and dry wool tops, put them into molten urea containing 7 times the weight of wool, and dissolve and react at 140°C for 1 hour;

[0043] S2, add 10 times the volume of NaHSO 4 Dissolve the aqueous solution, stir for 1 hour at the same time, use a cut-off 4-6kD dialysis bag, dialyze in distilled water for 30 hours, replace the distilled water every 15 hours, filter, filter and collect the filter residue, and dry to obtain hydrolyzed keratin with a molecular weight of 4-6kD;

[0044] S3, add 10 times the volume of Na to the filtrate 2 CO 3 Carry out alkaline hydrolysis, stir for 2 hours at the same time, use a cut-off quality 2-4kD dialysis bag, dialyze in mercaptoethanol 0.08% aqueous solution for 30 hours, replace mercaptoethanol 0.08% aqueous solution every 15 hours, filter and collect the filter ...

Embodiment 2

[0046] Embodiment 2 a kind of hydrolyzed liposome proteosome

[0047] The components and parts by weight of the hydrolyzed proteoliposome of Example 2 of the present invention are as shown in Table 1:

[0048] 40 parts of hydrolyzed keratin, 15 parts of ceramide-3, 150 parts of sitosterol, 5 parts of sodium deoxycholate, 110 parts of egg yolk lecithin, 13 parts of sesamol, 4 parts of carbomer, 1 part of essence, 1200 parts of trehalose parts, 120 parts of glycine;

[0049] The molecular weight of the hydrolyzed protein is a mixture of 4-6KD hydrolyzed protein and 2-4KD hydrolyzed protein; the weight fraction ratio of 4-6KD hydrolyzed protein and 2-4KD hydrolyzed protein is 1:0.6;

[0050]The preparation method of the hydrolyzed liposome specifically comprises the following steps:

[0051] 1) dissolving sitosterol and egg yolk lecithin in tert-butanol in a water bath at 85°C, and rotating to evaporate to obtain a uniform lipid film;

[0052] 2) Take hydrolyzed keratin, ceram...

Embodiment 3

[0055] Embodiment 3 a kind of hydrolyzed liposome proteosome

[0056] The components and parts by weight of the hydrolyzed proteoliposome of Example 3 of the present invention are as follows:

[0057] 45 parts of hydrolyzed keratin, 20 parts of ceramide-3, 130 parts of cholesterol, 5 parts of sodium cholate, 130 parts of sphingomyelin, 15 parts of tocopheryl acetate, 4 parts of carbomer, 1 part of essence, 1300 parts of trehalose , 130 parts of glycine;

[0058] The molecular weight of the hydrolyzed protein is a mixture of 4-6KD hydrolyzed protein and 2-4KD hydrolyzed protein; the weight fraction ratio of 4-6KD hydrolyzed protein and 2-4KD hydrolyzed protein is 1:0.7;

[0059] The preparation method of the hydrolyzed liposome specifically comprises the following steps:

[0060] 1) dissolving cholesterol and sphingomyelin in tert-butanol in a water bath at 75°C, and rotary evaporating to obtain a uniform lipid film;

[0061] 2) Take hydrolyzed keratin, ceramide-3, cholester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com