Foam material based on heteroporous covalent organic framework as well as preparation method and application thereof

A technology of covalent organic frameworks and foam materials, applied in chemical instruments and methods, inorganic chemistry, and other chemical processes, can solve the problems of slow adsorption speed and limited application, and achieve low cost, simple preparation method, and good practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

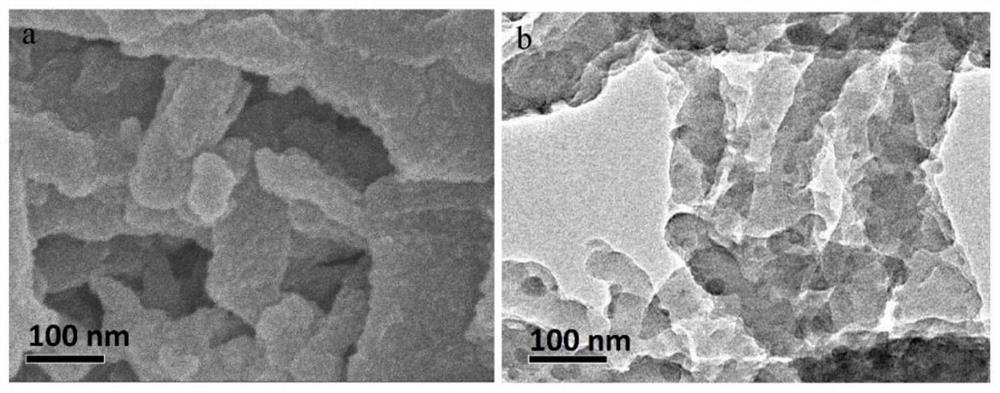

Image

Examples

Embodiment 1

[0043] 83 mg benzidine and 951 mg p-toluenesulfonic acid were ground in a mortar for 2 min to mix homogeneously, then, 49 mg trimesaldehyde was added to the mixture and continuously ground for 2 min to obtain a homogeneous mixture; due to benzidine and p-toluenesulfonic acid The mixing and grinding of the benzidine molecule makes the amino group (-NH 3+ ) and the sulfonic acid group (-SO 3- ), leading to the formation of p-toluenesulfonate, and then, the addition of trimesaldehyde triggers the Schiff base condensation reaction with benzidine, which finally generates covalent organic frameworks (COFs); benzidine, p- The material ratio of toluenesulfonic acid and trimesaldehyde is 0.45:5:0.3mmol, because the material prepared with this ratio has better crystallinity and faster adsorption speed for triphenylmethane dyes. Subsequently, 0.2 mL of deionized water was added to the above mixture and ground again for 15 min to form a paste.

[0044] Next, add 500mg of sodium bicarbon...

Embodiment 2

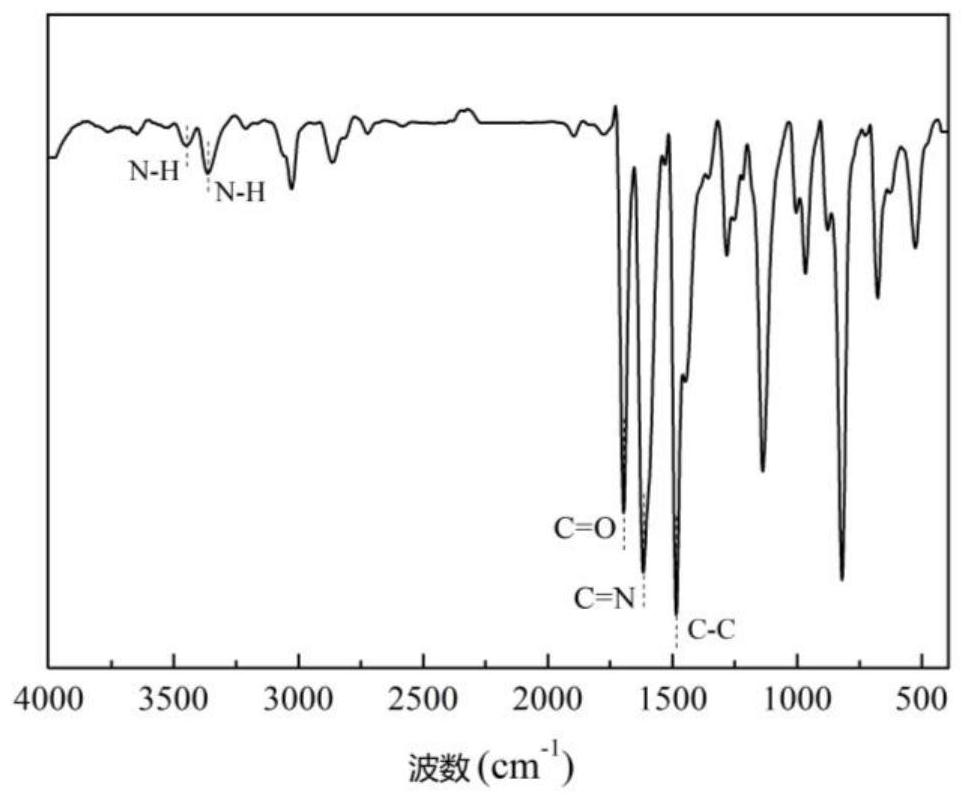

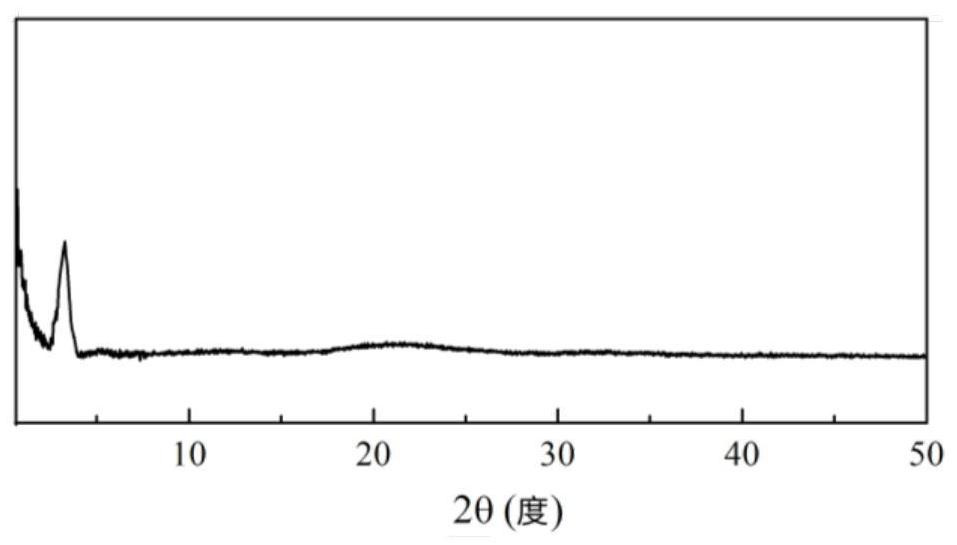

[0048] In order to analyze various properties of the TbBd-foam prepared in Example 1, infrared spectroscopy (FT-IR), X-ray diffraction (XRD), nitrogen-adsorption-desorption and thermogravimetric analysis were performed on it in this example.

[0049] Figure 2a shows the infrared spectrum of TbBd-foam, 3448cm -1 and 3363cm -1 The adsorption band at is attributed to the N-H stretching mode, 1695cm -1 The peak at and 1485cm -1 The absorption bands at are respectively assigned to C=O stretching and aromatic C-C ring stretching, 1616cm -1 The stretching at is attributed to the C=N stretching mode, which shows that the TbBd foam was successfully prepared by the Schiff base condensation reaction.

[0050] Figure 2b The XRD pattern of TbBd-foam is shown, and the diffraction peak of TbBd-foam at 3.26° matches the (100) plane, indicating that the product is well crystallized.

[0051] Figure 2c The nitrogen-adsorption-desorption isotherm diagram of TbBd-foam is shown, and TbBd...

Embodiment 3

[0055] In order to study the adsorption properties of the TbBd-foam prepared in Example 1, the following adsorption experiments were done in this example.

[0056] Experiment 1: Disperse 4.0 mg of TbBd-foam prepared in Example 1 in 4 mL of malachite green or crystal violet solution (first dissolve triphenylmethane dyes, malachite green and crystal violet with acetonitrile, and prepare 1 mg / mL stock solution, and then dilute the stock solution with deionized water to obtain triphenylmethane dyes (malachite green and crystal violet solutions) with a concentration of 2-100mg / L), and adsorb with the assistance of a vortex, and adsorb at 25°C for 30min. Then, centrifuge the two phases, and measure the concentration of free malachite green and crystal violet in the solution with a UV-visible spectrophotometer (the maximum ultraviolet absorption wavelengths of malachite green and crystal violet are 617nm and 590nm respectively).

[0057] Adsorption capacity q e (mg / g) is calculated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com