Ultraviolet curing composition glue as well as use method and application thereof

A composition and ultraviolet light technology, applied in non-polymer organic compound adhesives, adhesives, photovoltaic power generation and other directions, can solve the problems of low yield of packaged products, difficulty in taking into account light transmittance at the same time, and reducing light curing rate. , to achieve the effect of fast UV curing rate, excellent encapsulation effect, good inkjet printing and screen printing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

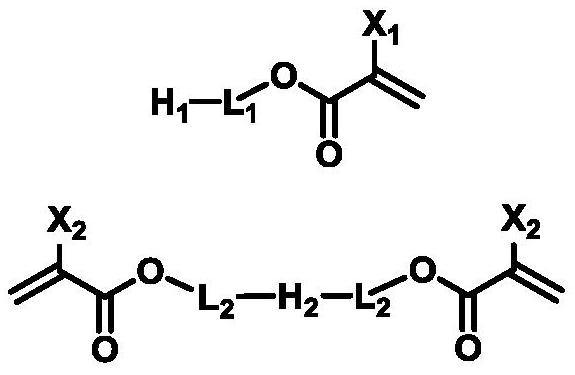

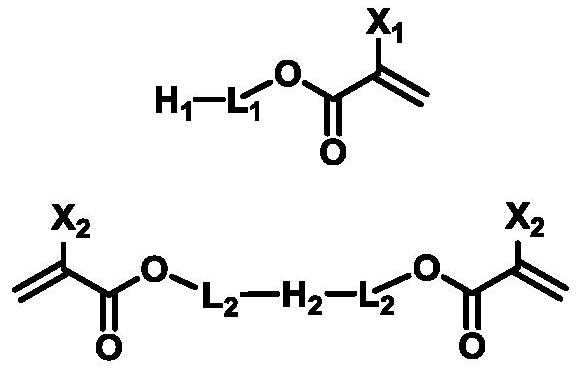

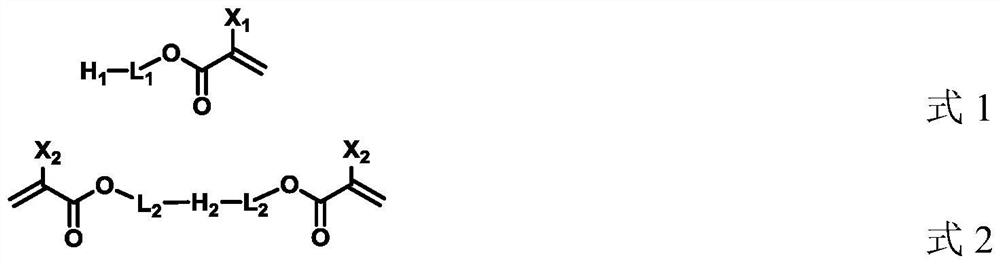

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the UV-curable composition glue is as follows:

[0043] According to the mass percentage, the photocurable monomer, the photocurable aromatic ring monomer and the photocrosslinking initiator are contained in a brown glass container, and stirred and mixed at room temperature until the photoinitiator is dissolved.

[0044] The method of using the UV-curable composition glue is as follows:

[0045] By means of inkjet printing, spin coating, screen printing or scraping coating, it is evenly attached to the surface of the electronic device to be packaged, and then irradiated by ultraviolet light to promote the formation of an organic barrier film. The present invention adopts the method of inkjet printing to print the glue of the UV-curable composition into a liquid film of a predetermined shape, and then adjust the power of the UV lamp at 10-500mW / cm 2 , irradiated for 1-300s for photocuring to obtain an organic film barrier layer with a thickness...

Embodiment 1

[0049] Synthesis of 2-(4-(4-fluorophenoxy)phenoxy)ethyl methacrylate

[0050]

[0051] In a nitrogen atmosphere, add 26.7 g of 4-bromo-2-fluoro-methoxybenzene, 6.2 g of ethylene glycol, 27.6 g of potassium carbonate, and 1.0 g of copper acetate to the reaction flask, heat to 130°C and stir for 24 hours, and the reaction mixture Cool to room temperature, wash with water and extract with dichloromethane to obtain an organic layer. Concentrate and remove dichloromethane after drying the organic layer with anhydrous sodium sulfate, and the residue is purified with a silica gel column to obtain 14.5 grams of 2-(4-(4-fluorophenoxy)phenoxy)ethan-1-alcohol; The resulting 2-(4-(4-fluorophenoxy)phenoxy)ethan-1-ol and 9.8 g of methacryloyl chloride were dissolved in 200 mL of pyridine, stirred at room temperature for 24 h in a nitrogen atmosphere, and then concentrated. The residue was washed with silica gel After column purification, 10.5 g of 2-(4-(4-fluorophenoxy)phenoxy)ethyl met...

Embodiment 2

[0055] Synthesis of 2-(3-fluoro-4-methoxyphenoxy)ethyl methacrylate

[0056]

[0057] In a nitrogen atmosphere, add 20.3 g of 4-bromo-2-fluoro-methoxybenzene, 6.2 g of ethylene glycol, 27.6 g of potassium carbonate, and 1.0 g of copper acetate into the reaction flask, heat to 130°C and stir for 24 hours, and the reaction mixture Cool to room temperature, wash with water and extract with dichloromethane to obtain an organic layer. The organic layer was dried over anhydrous sodium sulfate, concentrated to remove dichloromethane, and the residue was purified with a silica gel column to obtain 12.5 g of 2-(3-fluoro-4-methoxyphenoxy)ethyl-1-ol. Then, the obtained 2-(3-fluoro-4-methoxyphenoxy)ethyl-1-ol and 7.8 g of methacryloyl chloride were dissolved in 200 mL of pyridine, stirred at room temperature in a nitrogen atmosphere for 24 h, concentrated, and the residue was washed with silica gel After column purification, 11.5 g of 2-(3-fluoro-4-methoxyphenoxy)ethyl methacrylate wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com