Efficient composite carbon source for denitrification treatment of low-carbon-nitrogen-ratio wastewater and preparation method thereof

A low-carbon-to-nitrogen ratio and composite carbon source technology, applied in the field of water treatment, can solve the problems of not being able to meet the nutritional needs of microorganisms at the same time, increase operation and maintenance costs, etc., to maintain bacterial diversity, improve growth rate and carbon source. The rate of substrate utilization and the effect of regulating cell growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A high-efficiency composite biological carbon source agent for wastewater denitrification treatment, the high-efficiency composite biological carbon source agent is made of the following components in weight ratio: 25% glucose, 3% molasses, 3% sodium citrate, 10% glycerine Alcohol, 3% sodium formate, 4% sodium acetate, 1% potassium dihydrogen phosphate, 0.5% sodium dihydrogen phosphate, 0.2% zinc sulfate, 0.3% manganese sulfate, 0.2% biotin, 0.3% niacin, 49.5% water.

[0027] The denitrification influent and the sludge in a sewage treatment plant were taken for denitrification and denitrification experiments. Glucose, sodium citrate and glycerin were used as single carbon sources for comparison. Oxygen dosage is used. Except for the addition of different carbon sources, the test was carried out under the same conditions, and the total nitrogen in the effluent was used as a reference for carbon source evaluation.

[0028] The total nitrogen in the influent was 104.5mg / L...

Embodiment 2

[0030] A high-efficiency composite biological carbon source agent for wastewater denitrification treatment, the high-efficiency composite biological carbon source agent is made of the following components in weight ratio: 20% glucose, 4% molasses, 3% sodium citrate, 15% glycerine Alcohol, 3% sodium formate, 5% sodium acetate, 0.5% potassium dihydrogen phosphate, 0.5% dipotassium hydrogen phosphate, 1% sodium dihydrogen phosphate, 0.3% ammonium molybdate, 0.5% manganese sulfate, 0.2% copper sulfate, 0.2% Pyrimidine, 0.3% Biotin, 0.5% L-Glutamic Acid, 46% Water.

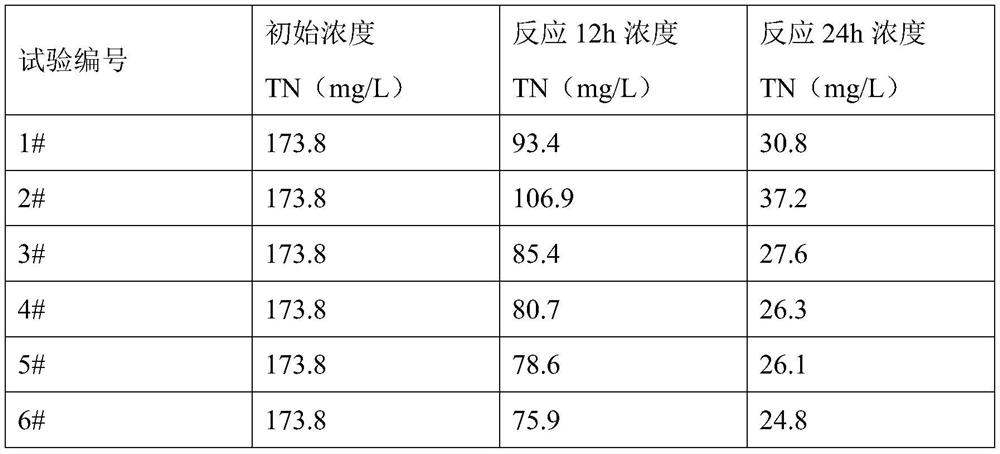

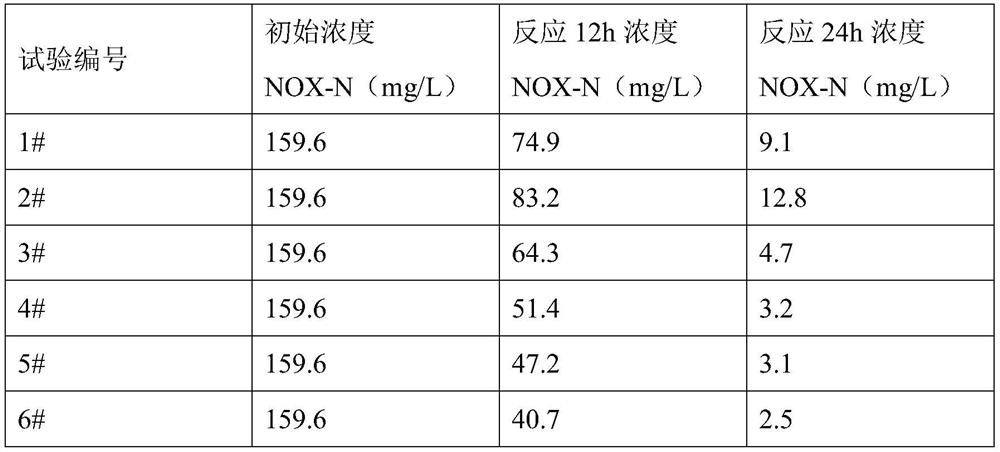

[0031] The denitrification influent and the sludge in a sewage treatment plant were taken for denitrification and denitrification experiments. Glucose, sodium citrate and glycerin were used as single carbon sources for comparison. Oxygen dosage is used. Except for the addition of different carbon sources, the test was carried out under the same conditions, and the total nitrogen in the effluent was used as a reference...

Embodiment 3

[0034] A high-efficiency composite biological carbon source agent for wastewater denitrification treatment, the high-efficiency composite biological carbon source agent is made of the following components in weight ratio: 15% glucose, 5% molasses, 5% sodium citrate, 20% glycerine Alcohol, 5% sodium formate, 8% sodium acetate, 1% trisodium phosphate, 1% potassium dihydrogen phosphate, 0.2% zinc sulfate, 0.3% manganese sulfate, 0.2% purine, 0.3% niacin, 1% L-glutamic acid , 38% water.

[0035] Take the denitrification influent and the sludge in the tank of a sewage treatment plant to conduct denitrification and denitrification experiments, and conduct denitrification and denitrification experiments in 4 devices. Add the prepared raw water and sludge mixture into the device respectively, and add the carbon source with the same amount of chemical oxygen demand. The following carbon source compositions added correspond to the device numbers one by one:

[0036] The composition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com