A super high temperature high strength toughness cement slurry system

An ultra-high-temperature, high-strength technology, which is applied in the field of oil and gas exploration and development, can solve the problems of unsatisfactory cementing operations in ultra-high-temperature, ultra-deep wells, complex formations, ultra-high-temperature cement stone strength decline, and insufficient ultra-high-temperature strength, so as to improve rheology And pumpability, good application performance, good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

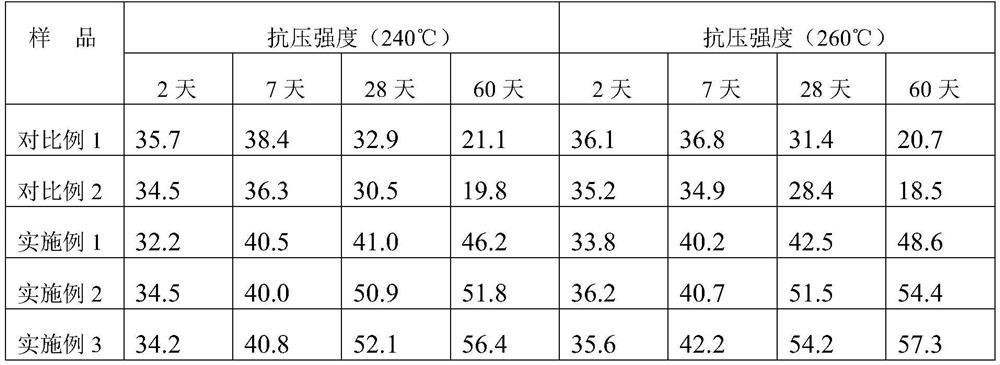

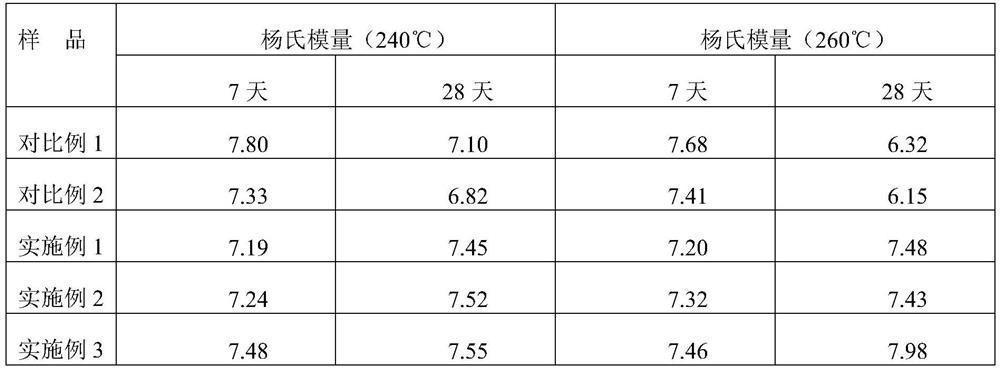

Embodiment 1

[0030] Formula: 100 parts of high sulfate-resistant G-grade oil well cement, 40 parts of 600-mesh acid-washed quartz sand, 10 parts of anti-high temperature strength decline material (100-mesh wollastonite and 100-mesh coke gemstone in a mass ratio of 1:1) , 3 parts of ultra-high temperature toughening agent halloysite nanotubes, 1 part of polycarboxylic acid dispersant, 3 parts of ultra-high temperature stabilizer (mass ratio of bentonite, magnesium aluminum silicate, and wenlun glue is 1:2:1), 2 parts of fluid loss reducer (patent application number 201910693705.9), 1.2 parts of retarder (patent number CN 104403056 B), 0.1 part of tributyl phosphate (defoamer), 55 parts of clear water.

[0031] The cement slurry preparation process is as follows: take 100 parts of oil well cement, 40 parts of 600-mesh acid-washed quartz sand, 10 parts of high-temperature strength decay resistance material, 3 parts of ultra-high temperature toughening agent halloysite nanotubes, 1 part of poly...

Embodiment 2

[0033]Formula: 100 parts of high sulfate-resistant G-grade oil well cement, 40 parts of 600-mesh acid-washed quartz sand, anti-high temperature strength decline material (100-mesh wollastonite and 200-mesh bauxite in a mass ratio of 1:1) 15 3 parts, 3 parts of ultra-high temperature toughening agent halloysite nanotubes, 1 part of polycarboxylic acid dispersant, 3 parts of ultra-high temperature stabilizer (the mass ratio of bentonite, magnesium aluminum silicate, and wenlun gum is 1:2:1) , 2 parts of water loss reducer (patent application number 201910693705.9), 1.2 parts of retarder (patent number CN 104403056 B), 0.1 part of tributyl phosphate (defoamer), 55 parts of water.

[0034] The cement slurry preparation process is as in Example 1.

Embodiment 3

[0036] Formula: 100 parts of high sulfate-resistant G-grade oil well cement, 40 parts of 600-mesh acid-washed quartz sand, anti-high temperature strength decline material (200-mesh kyanite and 200-mesh bauxite compounded at a mass ratio of 1:1) 15 3 parts, 3 parts of ultra-high temperature toughening agent halloysite nanotubes, 1 part of polycarboxylic acid dispersant, 3 parts of ultra-high temperature stabilizer (the mass ratio of bentonite, magnesium aluminum silicate, and wenlun gum is 1:2:1) , 2 parts of water loss reducer (patent application number 201910693705.9), 1.2 parts of retarder (patent number CN 104403056 B), 0.1 part of tributyl phosphate (defoamer), 55 parts of water.

[0037] The cement slurry preparation process is as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com