A kind of anti-high temperature gel plugging agent for oil-based drilling fluid and its preparation method and application

A technology of oil-based drilling fluid and loss-stopping agent, which is applied in chemical instruments and methods, earth-moving drilling and production, wellbore/well components, etc. Leakage, inability to apply to high temperature formations, etc., to achieve the effects of low cost, small performance impact, and controllable crosslinking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

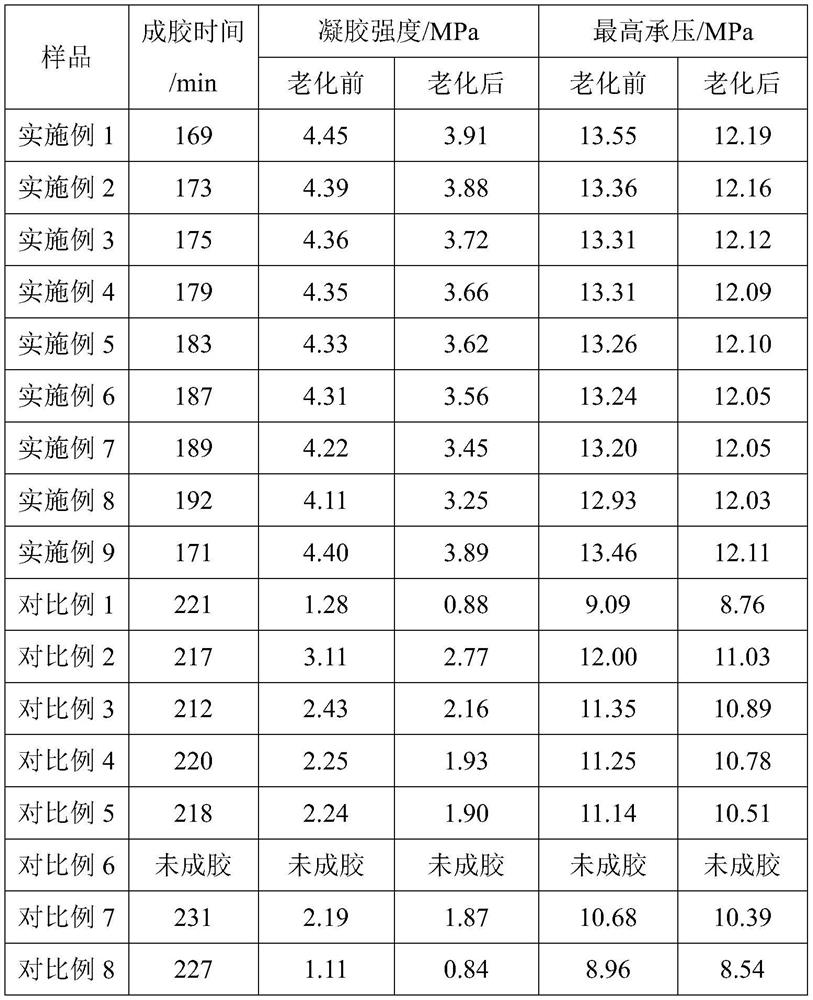

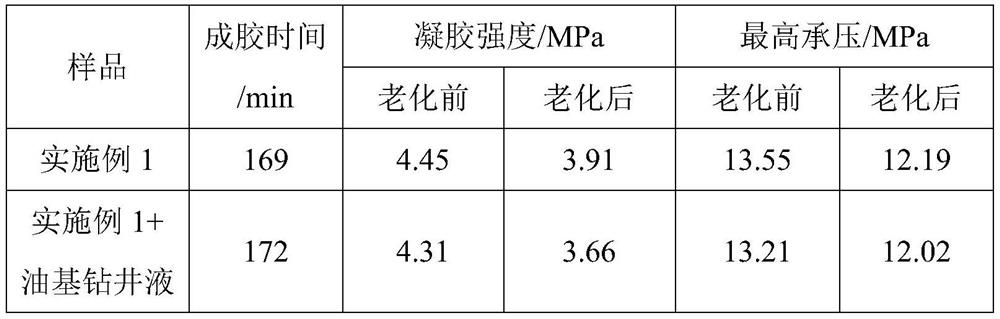

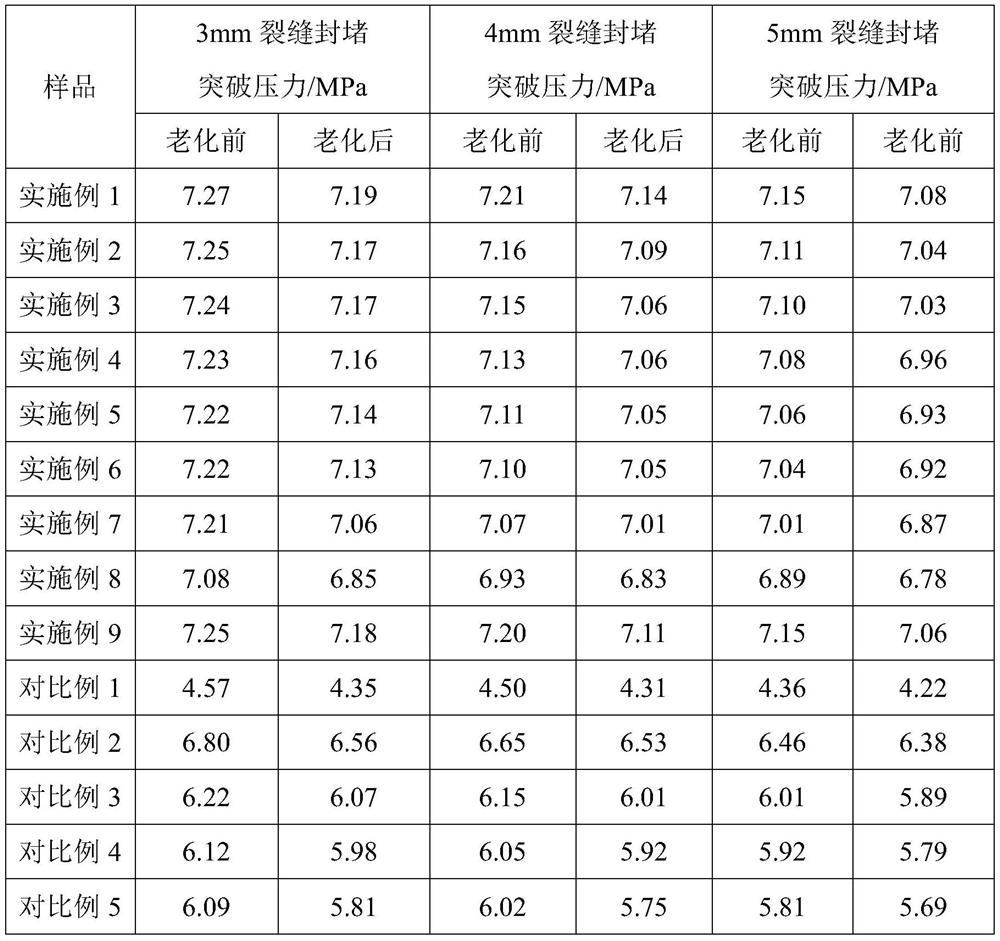

Examples

Embodiment 1

[0035] An anti-high temperature gel plugging agent for oil-based drilling fluid, comprising the following raw materials in parts by weight: 22 parts of a gelling agent, 5 parts of a crosslinking agent, 0.8 parts of an initiator, and 73.2 parts of a base oil;

[0036] Wherein, the gelling agent is a combination of diethylene glycol dimethacrylate and cetyl methacrylate, and the mass ratio of diethylene glycol dimethacrylate and cetyl methacrylate is 1 : 2; the crosslinking agent is the combination of dibutylammonium oleate and zinc acrylate, and the mass ratio is 1:1; the initiator is azobisisobutyronitrile; the base oil is white oil.

[0037] The preparation method of the above-mentioned high temperature anti-high temperature gel plugging agent for oil-based drilling fluid comprises the following steps:

[0038] (1) adding the gelling agent to the white oil at 40°C, then warming up to 50°C, at 50°C, stirring at a stirring rate of 500 rev / min for 25min to dissolve it completely...

Embodiment 2

[0042] An anti-high temperature gel plugging agent for oil-based drilling fluid, comprising the following raw materials in parts by weight: 22 parts of a gelling agent, 5 parts of a crosslinking agent, 0.4 parts of an initiator, and 72.6 parts of a base oil;

[0043] Wherein, the gelling agent is a combination of diethylene glycol dimethacrylate and cetyl methacrylate, and the mass ratio of diethylene glycol dimethacrylate and cetyl methacrylate is 1 : 2; the crosslinking agent is the combination of dibutylammonium oleate and zinc acrylate, and the mass ratio is 1:1; the initiator is azobisisobutyronitrile; the base oil is white oil.

[0044] The preparation method of the above-mentioned high temperature anti-high temperature gel plugging agent for oil-based drilling fluid is as described in Example 1.

Embodiment 3

[0046] An anti-high temperature gel plugging agent for oil-based drilling fluid, comprising the following raw materials in parts by weight: 22 parts of gelling agent, 7 parts of crosslinking agent, 0.8 part of initiator, and 70.2 parts of base oil;

[0047] Wherein, the gelling agent is a combination of diethylene glycol dimethacrylate and cetyl methacrylate, and the mass ratio of diethylene glycol dimethacrylate and cetyl methacrylate is 1 : 2; the crosslinking agent is the combination of dibutylammonium oleate and zinc acrylate, and the mass ratio is 1:1; the initiator is azobisisobutyronitrile; the base oil is white oil.

[0048] The preparation method of the above-mentioned high temperature anti-high temperature gel plugging agent for oil-based drilling fluid is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com