Sandwich structure giant magneto-impedance effect composite material and preparation method

A technology of giant magneto-impedance and composite materials, applied in the field of magnetic sensitive components, can solve the problems such as the inability of the giant magneto-impedance value to be significantly improved and the magnetic flux path to be unable to be well closed, to enhance the GMI effect, suitable for mass production, The effect of increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

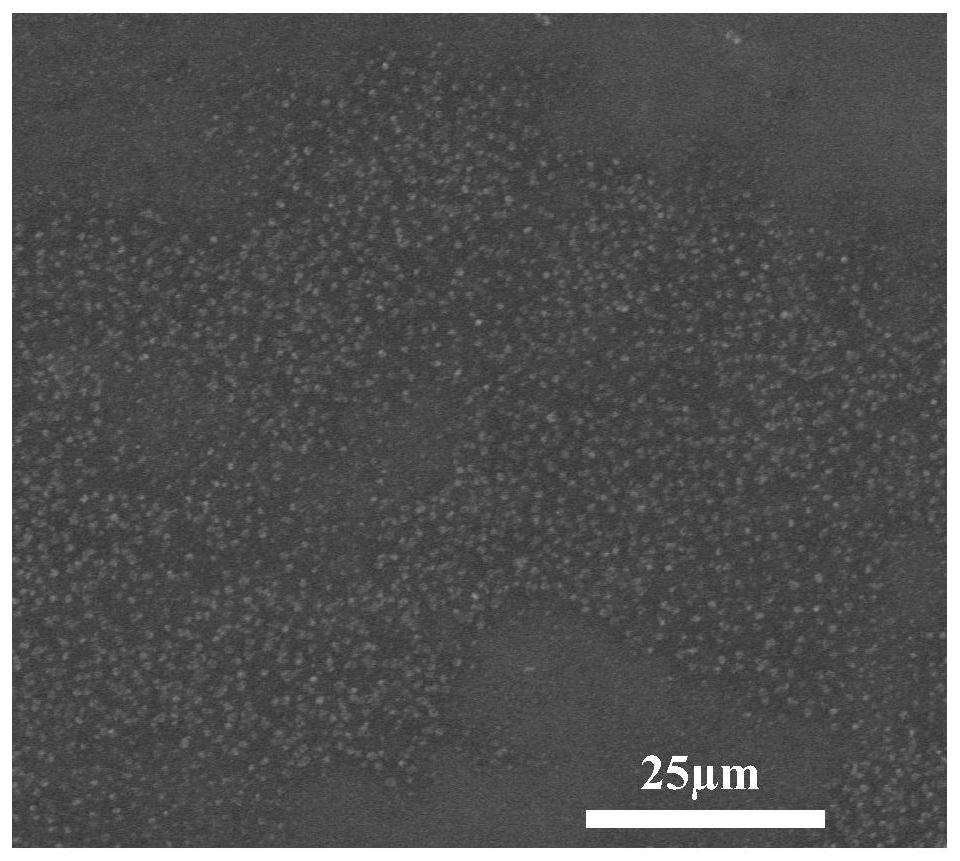

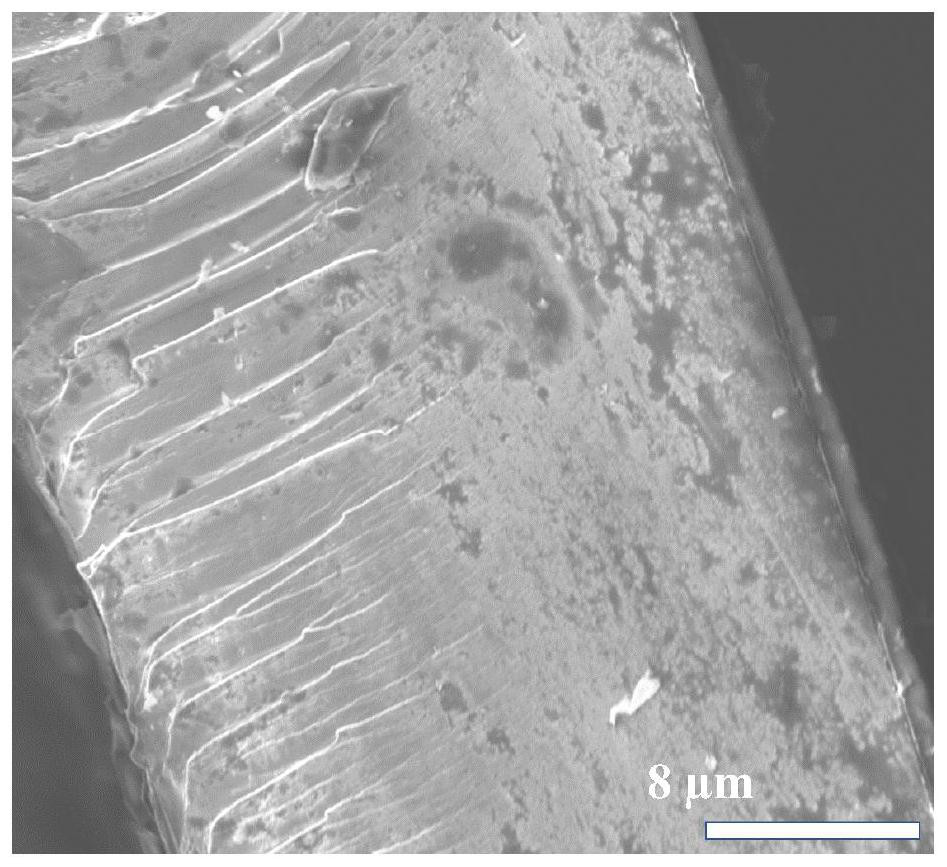

[0029] Step 1: Take iron-based amorphous Fe 73.5 Cu 1 Nb 3 Si 13 B 9.5 one strip;

[0030] Step 2: Place the iron-based amorphous strip in step 1 in a tube furnace, set the vacuum degree to 1.5 Pa, raise the temperature to 540° C., inject 5 sccm of hydrogen, and anneal for 20 minutes to obtain the iron-based nanocrystalline strip;

[0031] Step 3: Place the iron-based nanocrystalline strips obtained in step 2 in 0.4M NaOH, 0.5 M NaOH 2 CO 3 and 0.7M Na 3 PO 4 12H 2 Carry out degreasing and cleaning treatment in the mixed solution of O, and processing time is 10 minutes;

[0032] Step 4: Place the strips obtained in Step 3 in 5M HCl solution for acidification, and the treatment time is 20 minutes;

[0033] Step 5: Place the strips obtained in step 4 in 0.3M SnCl 2 · 2H 2 Sensitization treatment was carried out in the mixed solution of HCl of O and 0.6M, and the treatment time was 20 minutes;

[0034] Step 6: Place the strip obtained in step 5 on a 2.5×10 -4 M PdCl...

Embodiment 2

[0043] Step 1: Take iron-based amorphous Fe 73.5 Cu 1 Nb 3 Si 13 B 9.5 one strip;

[0044] Step 2: Place the iron-based amorphous strip in step 1 in a tube furnace, set the vacuum degree to 1.9 Pa, raise the temperature to 540° C., inject 5 sccm of hydrogen, and anneal for 20 minutes to obtain the iron-based nanocrystalline strip;

[0045] Step 3: Place the iron-based nanocrystalline strips obtained in step 2 in 0.4M NaOH, 0.5 M NaOH 2 CO 3 and 0.7M Na 3 PO 4 12H 2 Carry out the degreasing cleaning process in the mixed solution of O, and the processing time is 20 minutes;

[0046] Step 4: Place the strips obtained in Step 3 in 5M HCl solution for acidification, and the treatment time is 20 minutes;

[0047] Step 5: Place the strips obtained in step 4 in 0.3M SnCl 2 · 2H 2 Sensitization treatment was carried out in the mixed solution of HCl of O and 0.6M, and the treatment time was 20 minutes;

[0048] Step 6: Place the strip obtained in step 5 on a 2.5×10 -4 M Pd...

Embodiment 3

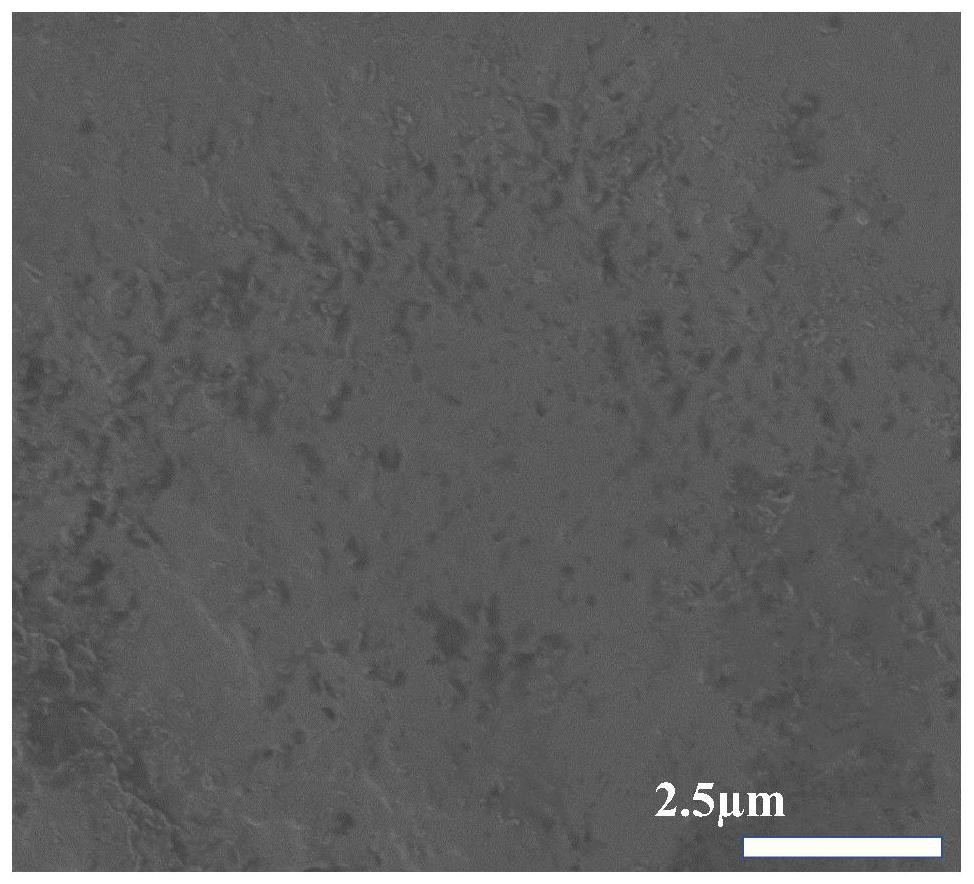

[0057] Step 1: Take iron-based amorphous Fe 73.5 Cu 1 Nb 3 Si 13 B 9.5 one strip;

[0058] Step 2: Place the iron-based amorphous strip in step 1 in a tube furnace, set the vacuum degree to 2pa, raise the temperature to 540°C, inject 5 sccm of hydrogen, and anneal for 20 minutes to obtain the iron-based nanocrystalline strip;

[0059] Step 3: Place the iron-based nanocrystalline strips obtained in step 2 in 0.4M NaOH, 0.5 M NaOH 2 CO 3 and 0.7M Na 3 PO 4 12H 2 Carry out degreasing and cleaning treatment in the mixed solution of O, and processing time is 10 minutes;

[0060] Step 4: Place the strips obtained in Step 3 in 5M HCl solution for acidification, and the treatment time is 20 minutes;

[0061] Step 5: Place the strips obtained in step 4 in 0.3M SnCl 2 · 2H 2 Sensitization treatment was carried out in the mixed solution of HCl of O and 0.6M, and the treatment time was 10 minutes;

[0062] Step 6: Place the strip obtained in step 5 on a 2.5×10 -4 M PdCl 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com