Preparation method of continuous carbon nanofiber bundle and preparation method of continuous carbon nanofiber cloth

A nano-carbon fiber, fibril technology, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve problems such as poor fiber uniformity and affecting fiber mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a continuous carbon nanofiber bundle, wherein the method may comprise the following steps:

[0024] (1) Spinning solution configuration: Dissolve the polymer resin or powder in the solvent and fully stir, let it stand for defoaming, and obtain a uniform spinning system as the electrostatic spinning solution;

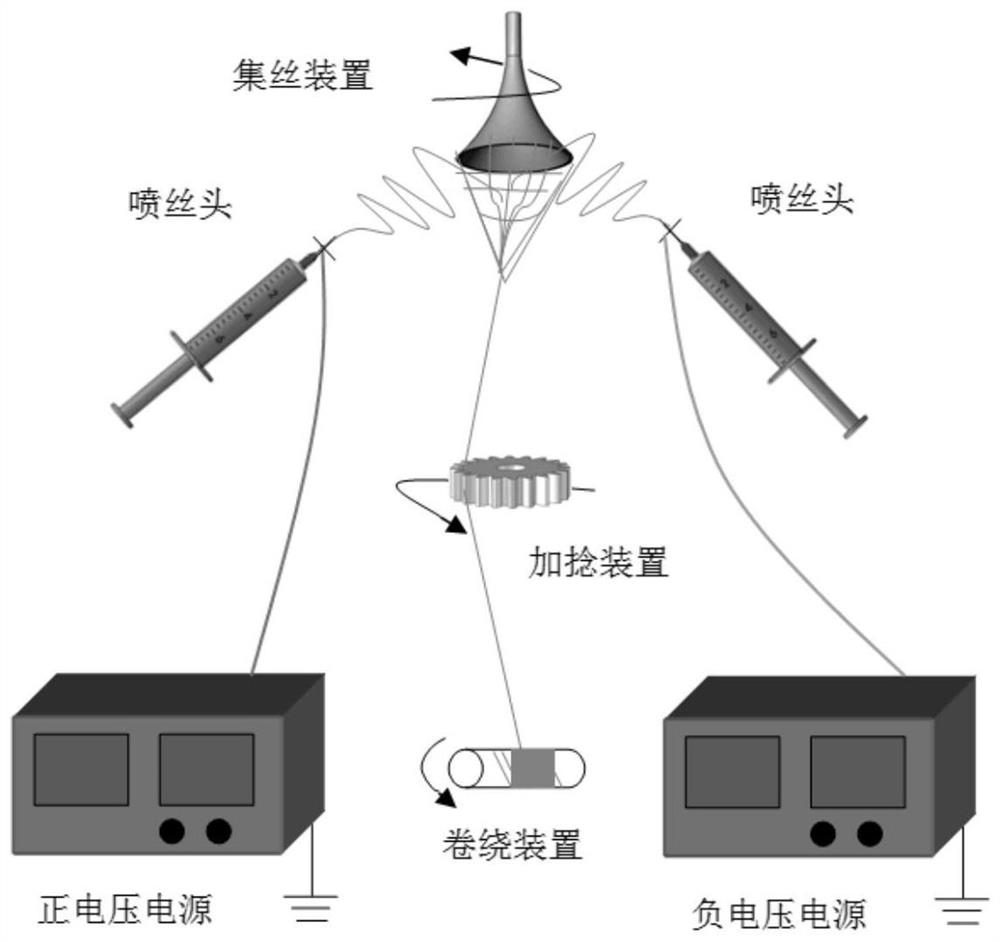

[0025] (2) Preparation of precursor fiber bundles: electrospinning the electrospinning solution to obtain continuous fibril bundles or fibril-wrapped yarns with directional arrangement;

[0026] (3) Preparation of carbon nanofiber bundles by high-temperature sintering: first pre-oxidize the fibril bundles or fibril-wrapped yarns in an air atmosphere, and then perform high-temperature sintering on the fibril bundles by segmental heat treatment to prepare carbon nanofiber bundles.

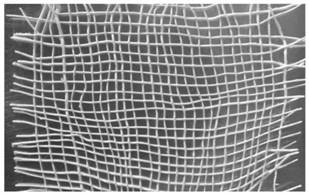

[0027] The present invention provides a kind of preparation method of continuous nanometer carbon fiber cloth, wherein this method can compr...

Embodiment 1

[0044] A method for preparing a continuous carbon nanofiber bundle, comprising the following steps:

[0045] (1) At 30°C, add 14g of polyacrylonitrile (PAN) powder into N,N-dimethylformamide, stir at a rate of 600r / min for 4 to 6 hours until completely dissolved, and the solution is light yellow and transparent Liquid, the PAN / DMF solution that obtains mass fraction is 14wt%;

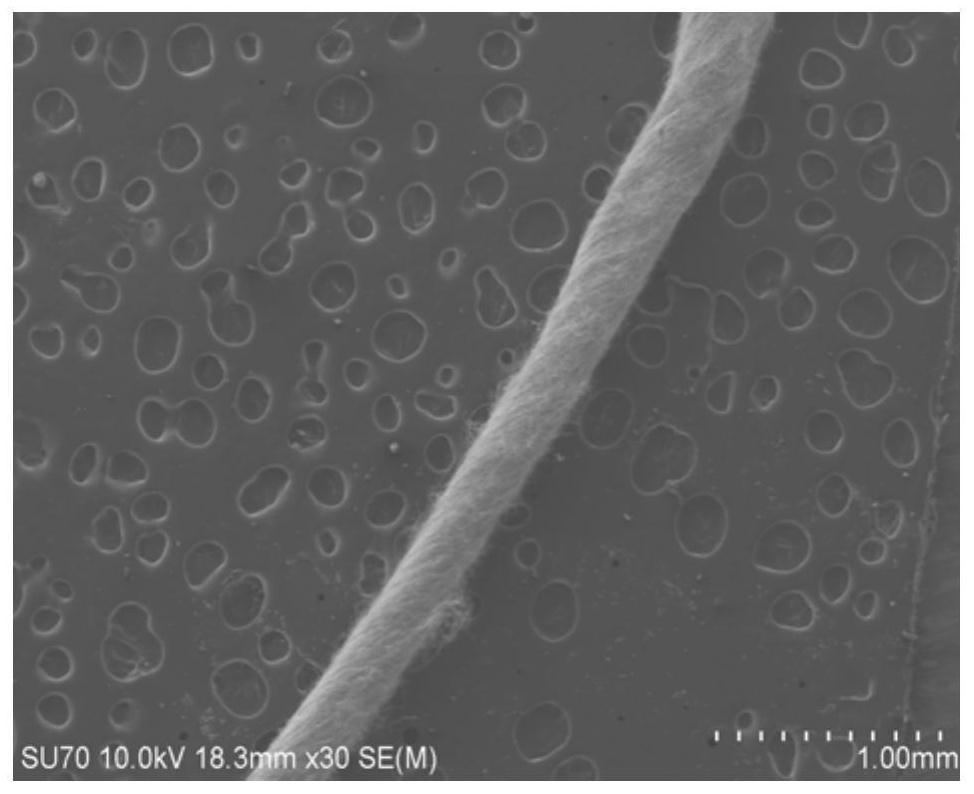

[0046] (2) Use two medical syringes to extract 10ml of the prepared PAN / DMF solution respectively. The metal hollow needle of the syringe is 8#, fix the two needles, and connect them to the high-voltage positive power supply and the high-voltage negative power supply respectively. The inclination angles were 0° and 15° respectively; the extrusion rates were controlled to be 0.8ml / h and 1.0ml / h respectively, and the electrospinning was carried out under the voltage conditions of 18kV and -18kV; The collected fibers are twisted at a high speed, and finally a continuous directional array of precursor fibe...

Embodiment 2

[0049] A method for preparing a continuous nanometer hollow carbon fiber bundle, comprising the following steps:

[0050] (1) At 30°C, add 14g of polyacrylonitrile (PAN) powder into N,N-dimethylformamide, stir at a rate of 600r / min for 4 to 6 hours until completely dissolved, and the solution is light yellow and transparent Liquid, the PAN / DMF solution that obtains mass fraction is 14wt%;

[0051] (2) Use two medical syringes to extract 10ml of the prepared PAN / DMF solution respectively. The metal hollow needle of the syringe is 8#, fix the two needles, and connect them to the high-voltage positive power supply and the high-voltage negative power supply respectively. The inclination angles were 0° and 15°; the extrusion rates were controlled to be 0.8ml / h and 1.0ml / h respectively, and the electrospinning was carried out under the voltage conditions of 18kV and -18kV; the bobbin of the textile yarn was fixed on On the yarn supply roller of the electrospinning nanofiber bundle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com