Lignocellulose raw material continuous treatment method

A technology of lignocellulose and a treatment method, which is applied in the field of comprehensive utilization of biomass, can solve the problems of acidification and oxidation treatment being difficult to promote on a large scale, not yet popularized on a large scale, and cumbersome to prepare straws, so as to improve the pretreatment effect and the treatment effect. , the effect of continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

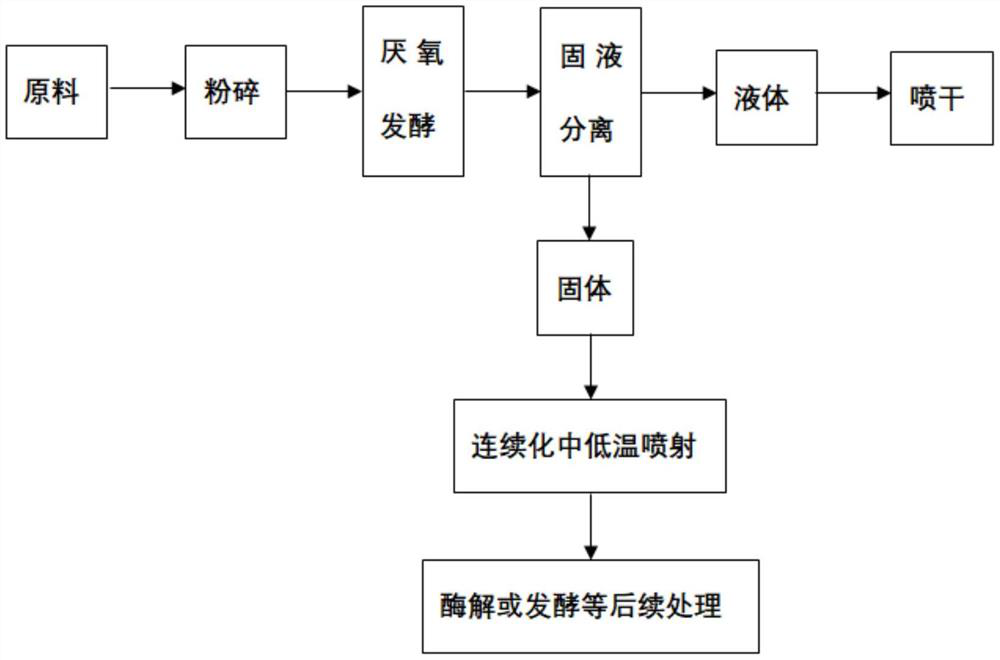

[0028] refer to figure 1 , a kind of lignocellulose continuous processing method, comprises the steps:

[0029] Step 1), crush 1 kg of agricultural and forestry waste wheat straw to 1 to 2 cm, add water in a ratio of 1:2 to water, add bacillus, compact and block, place in a closed anaerobic Sealed anaerobic fermentation in a fermentation bag at room temperature for 7 days.

[0030] Step 2), after the fermentation has a sour aroma, the fermented lignocellulose raw material is subjected to solid-liquid separation using a plate and frame filter press, and the liquid part is concentrated (25% in solid content) and mixed with a soluble carrier maltodextrin ( Add maltodextrin 25kg per 100kg concentrate) and mix and dry to obtain 289 grams of directional feed additive product biological enzyme (which is rich in compound beneficial microorganisms (including spores, yeasts, lactic acid bacteria, butyric acid bacteria) and their metabolites, short chain fatty acid enzyme product). Th...

Embodiment 2

[0035] A method for continuous processing of lignocellulose, comprising the steps of:

[0036] Step 1), crush 1 kg of agricultural and forestry waste leaves to 1-2 cm, add water to make the moisture content of the raw material 65%, add yeast, compact and block, seal the anaerobic in a closed anaerobic bucket at room temperature Fermented for 15 days.

[0037] Step 2), after the fermentation has a sour flavor, a screw extruder is used to separate the fermented lignocellulose raw material from solid and liquid, and the liquid part is concentrated (solid content concentration 30%) and mixed with the insoluble carrier bran for drying to obtain The directional feed additive product biological enzyme is 306 grams, and the drying method is scraper drying. The solid part enters the next process.

[0038] Step 3), the solid part (water content 70%) in step 2) is mixed with solid potassium hydroxide in a weight ratio of 15:1, and water with a weight ratio of 8:1 to the solid part is a...

Embodiment 3

[0042] A method for continuous processing of lignocellulose, comprising the steps of:

[0043] Step 1), crush 1 kg of agricultural and forestry waste corn stalks to 1 to 2 cm, add water in a ratio of 1:3 to water, add lactic acid bacteria, compact and block, and place in a closed anaerobic pool Sealed anaerobic fermentation at medium and room temperature for 10 days.

[0044] Step 2), after the fermentation has a sour aroma, the fermented lignocellulose raw material is subjected to solid-liquid separation using a plate and frame filter press, and the liquid part is concentrated (solid content 20%) and then mixed with the soluble carrier cyclodextrin Dry to obtain 276 grams of directional feed additive product bio-ferment, and the drying method is oven drying. The solid part enters the next process.

[0045] Step 3), by weight, the water content of the solid part is 60%, mixed with solid calcium hydroxide in a weight ratio of 12:1, and adding water with a weight ratio of 6:1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com