Two-dimensional gamma-graphdiyne powder and preparation method thereof

A powder and single alkyne technology, applied in the field of two-dimensional carbon material semiconductor, can solve the problems of weak controllability, high energy consumption, and high power requirements in the experimental process, and achieves low toxicity, low energy consumption, and easy application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] This embodiment provides a kind of preparation method of γ-graphite monoyne powder, and concrete steps are:

[0031] (1) After the calcium carbide is crushed and ground, use a ball mill to perform ball milling on the initially crushed calcium carbide and hexabromobenzene for a short period of time to refine the particle size, and the ball milling time is 0.5h to 1.5h;

[0032] (2) After ball milling, calcium carbide and hexabromobenzene are mixed with a solvent to make a slurry, the mouth of the slurry container is sealed, and stirred at a constant temperature at a temperature of 75°C to 85°C to make the slurry coupling reaction, and after the reaction is completed, the slurry is dried;

[0033] (3) Anneal the powder obtained by drying in a tube furnace under an argon or nitrogen atmosphere at an annealing temperature of 300°C to 700°C to volatilize residual hexabromobenzene;

[0034] (4) powder after annealing, carry out dilute acid washing, deionized water washing and...

Embodiment 1

[0043] Prepare hexabromobenzene and calcium carbide at a molar ratio of 1:5.75. After crushing and grinding 4g of calcium carbide, add 14mL of absolute ethanol for 1h ball milling; add 6g of hexabromobenzene and 14mL of absolute ethanol for 1h ball milling; After the slurry is mixed, add absolute ethanol to 150mL, stir evenly at room temperature, and stir at a constant temperature of 80°C for 28h. The mixed slurry was dried at 70°C; the dried powder was annealed in a tube furnace at 400°C for 2 hours in an argon atmosphere; after annealing, the powder was washed with dilute nitric acid, deionized water, and absolute ethanol in sequence; After drying at 70°C, black fluffy γ-graphyne powder was obtained without further treatment. The final sample is as follows: figure 1 Photos shown.

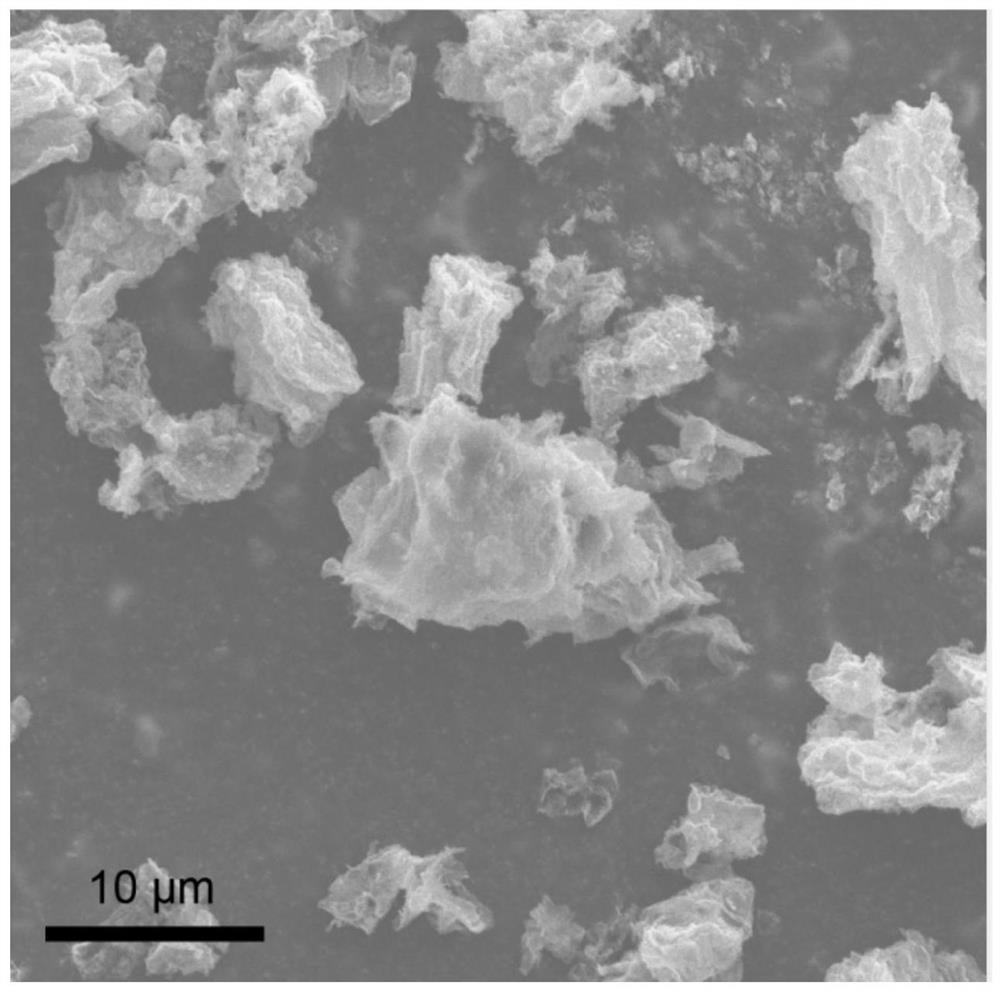

[0044] figure 2 For the SEM photo of the black fluffy γ-graphite monoyne powder obtained in Example 1, it can be seen that the sample is stacked by many flakes and has a large specific surface ...

Embodiment 2

[0046] Prepare hexabromobenzene and calcium carbide according to the molar ratio of 1:12, crush and grind 2.91g of calcium carbide, add 20mL of absolute ethanol for 1h ball milling; add 2.09g of hexabromobenzene, add 20mL of absolute ethanol for 1h ball milling; After mixing the slurry obtained by ball milling, add absolute ethanol to 150mL, stir evenly at room temperature, and stir at a constant temperature of 80°C for 23h. The final mixed slurry was dried at 70°C; the dried powder was annealed in a tube furnace at 400°C for 2 hours in a nitrogen atmosphere; after annealing, the powder was washed with dilute nitric acid, deionized water, and absolute ethanol in sequence; After drying at 70°C, black fluffy γ-graphyne powder was obtained without further treatment.

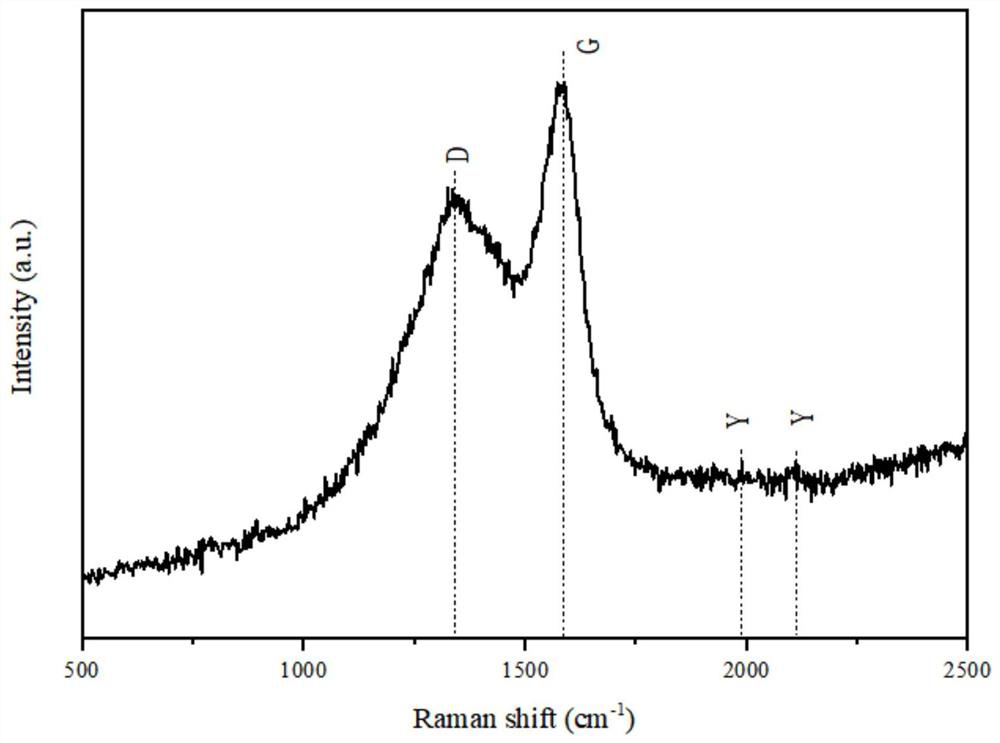

[0047] Figure 7 For the black fluffy γ-graphite monoyne powder SEM photograph that embodiment 2 obtains, it can be seen that the sample is stacked by many flakes and has a large specific surface area; Figure 8 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com