Rhodium-doped titanium dioxide composite material, preparation method and photocatalytic application thereof

A technology of titanium dioxide and composite materials, applied in the field of visible light catalytic materials and their preparation, can solve the problems of no photocatalytic activity, expensive equipment, and difficulty in obtaining Rh, and achieves good visible light catalytic performance, excellent catalytic performance, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

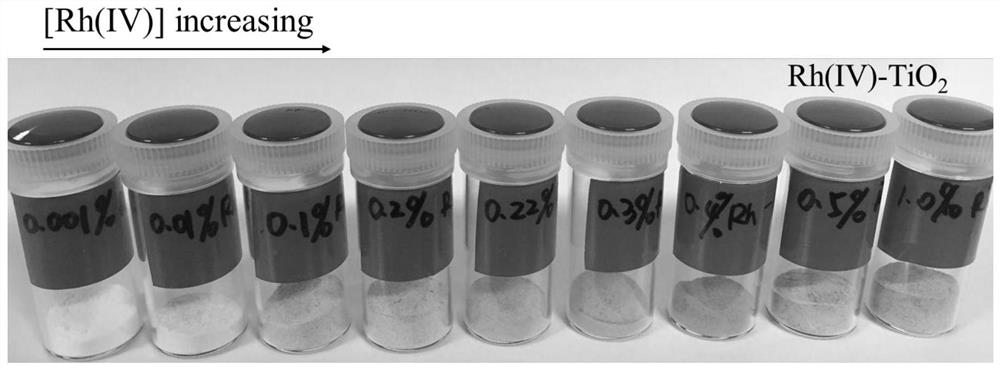

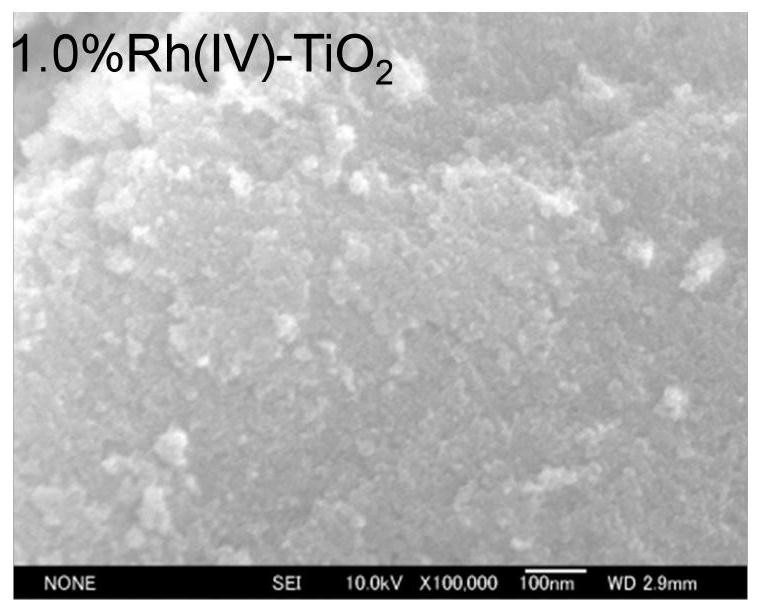

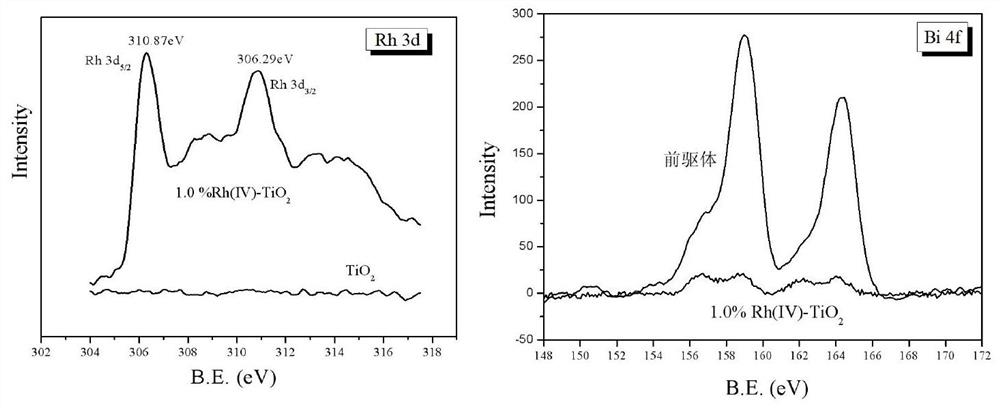

[0030] Embodiment 1 rhodium-doped titanium dioxide (Rh (IV)-TiO 2 ) composite material (Rh(IV) / Ti=1.0mol%)

[0031] The preparation method of the above-mentioned visible light photocatalytic material comprises the following steps:

[0032] A. Mix 5.85mL of dilute nitric acid (2mol / L), 0.15mL RhCl 3 (0.1mol / L) solution and 0.1g sodium bismuthate powder are added in the round-bottomed flask successively, cover the stopper and stir well to obtain purple solution containing Rh(IV) after 20 hours.

[0033] B. Add 4 mL of n-butyl titanate dropwise to 37.6 mL of ultrapure water, and stir continuously for 30 minutes to allow the hydrolysis reaction to fully occur, then add 1.67 mL of the solution containing Rh(IV) freshly prepared in step A, and continue stirring 10min. Finally, the suspension was transferred into a reaction kettle for hydrothermal reaction at 180° C. for 10 hours. After hydrothermal reaction, ethanol washing and water washing were carried out several times in seq...

Embodiment 2

[0040] Embodiment 2 rhodium-doped titanium dioxide (Rh (IV)-TiO 2 ) composite material (Rh(IV) / Ti=0.01mol%)

[0041] The preparation method of the above-mentioned visible light photocatalytic material comprises the following steps:

[0042] A. Mix 5.85mL of dilute nitric acid (2mol / L), 0.15mL RhCl 3 (0.1mol / L) solution and 0.1g sodium bismuthate powder are added in the round-bottomed flask successively, cover the stopper and stir well to obtain purple solution containing Rh(IV) after 20 hours.

[0043] B. Add 4mL of n-butyl titanate dropwise to 43mL of ultrapure water, stir continuously for 30min to make it fully hydrolyzed, then add 0.45mL of the solution containing Rh(IV) freshly prepared in step A, and continue stirring for 10min . Finally, the suspension was transferred into a reaction kettle for hydrothermal reaction at 180° C. for 10 hours. After hydrothermal reaction, ethanol washing and water washing were carried out several times in sequence, and a gray precursor ...

Embodiment 3

[0050] Embodiment 3 rhodium-doped titanium dioxide (Rh (IV)-TiO 2 ) composite material (Rh(IV) / Ti=0.22mol%)

[0051] The preparation method of the above-mentioned visible light photocatalytic material comprises the following steps:

[0052] A. Mix 5.85mL of dilute nitric acid (2mol / L), 0.15mL RhCl 3 (0.1mol / L) solution and 0.1g sodium bismuthate powder are added in the round-bottomed flask successively, cover the stopper and stir well to obtain purple solution containing Rh(IV) after 20 hours.

[0053] B. Add 4 mL of n-butyl titanate dropwise to 34 mL of ultrapure water, and stir continuously for 30 minutes to allow the hydrolysis reaction to fully occur, then add 10 mL of the solution containing Rh(IV) freshly prepared in step A, and continue stirring for 10 minutes. Finally, the suspension was transferred into a reaction kettle for hydrothermal reaction at 180° C. for 10 hours. After hydrothermal reaction, ethanol washing and water washing were carried out several times i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com