Ozone catalytic oxidation wastewater treatment device and treatment method

A technology of ozone catalytic oxidation and wastewater treatment, which is applied in the direction of oxidized water/sewage treatment, special compound water treatment, water/sewage treatment, etc., can solve the problems of low efficiency, high cost, large volume, etc., and achieve high mass transfer efficiency, The effect of reducing loss and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In order to make the present invention clearer, a kind of ozone catalytic oxidation wastewater treatment device and treatment method of the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

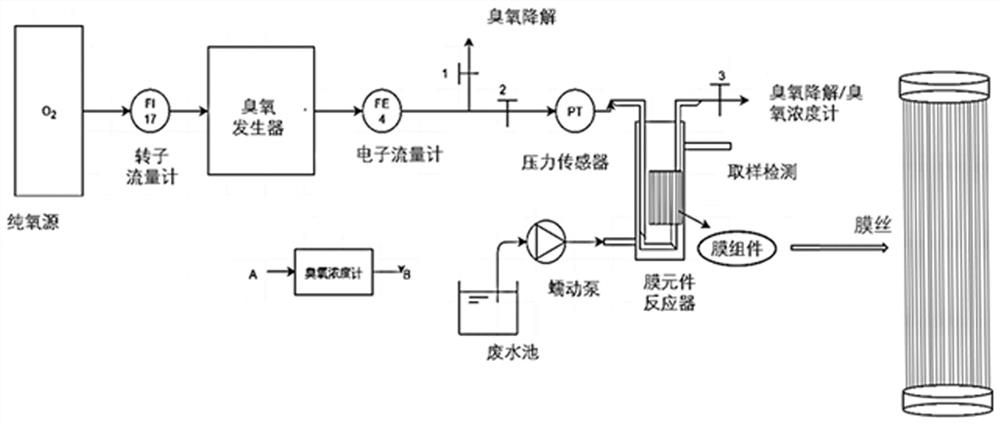

[0047] Such as figure 1 Shown, a kind of ozone catalytic oxidation wastewater treatment device is characterized in that:

[0048] Including pure oxygen source bin, ozone generator and membrane element reactor connected in sequence, a rotameter is set between the pure oxygen source bin and the ozone generator, and an electronic flowmeter is set between the ozone generator and the membrane element reactor There is a first ball valve and a second ball valve between the electronic flow meter and the pressure sensor. A membrane module for sewage treatment is installed in the membrane element reactor, an...

Embodiment 2

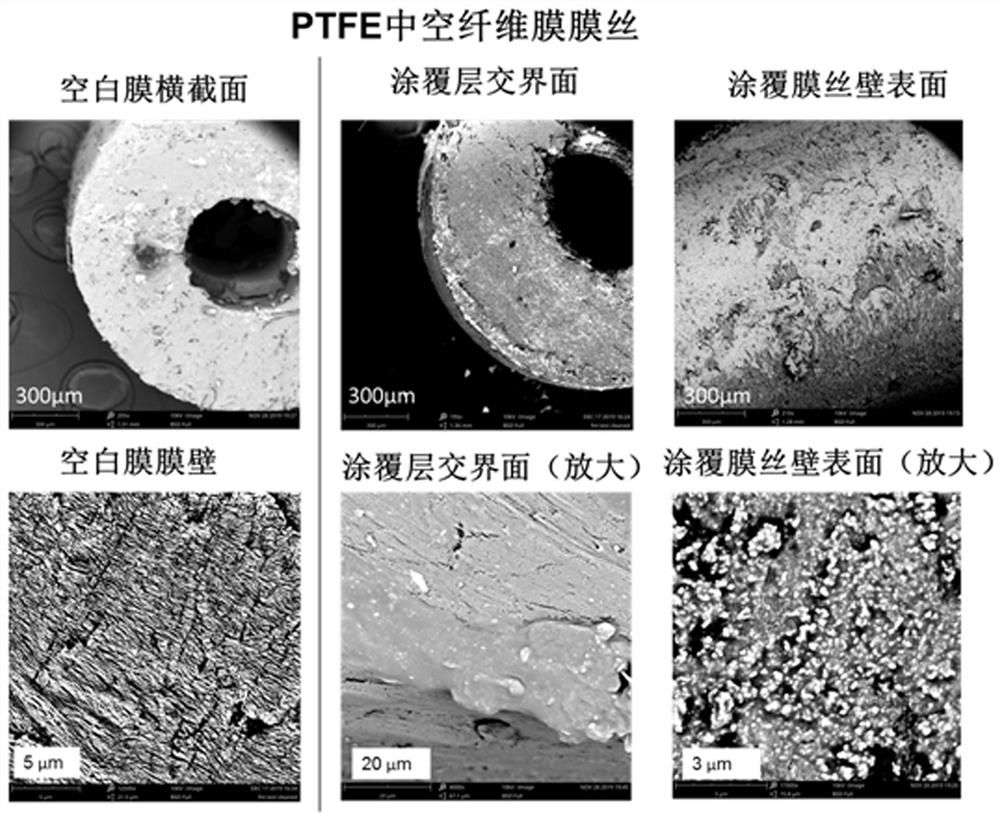

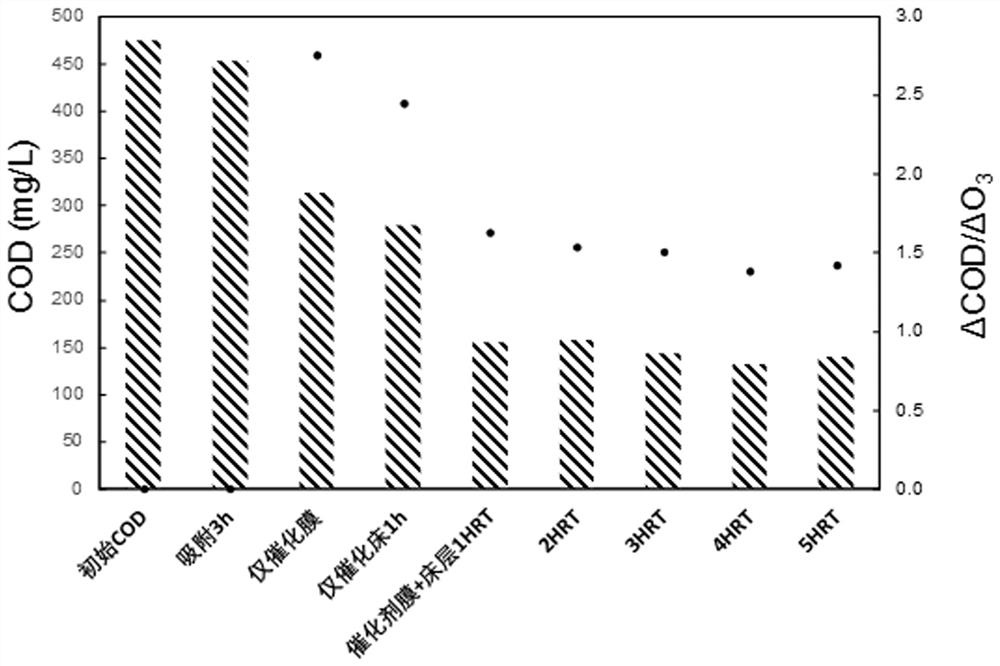

[0062] For the PTFE hollow fiber membrane coated by the method of the present invention, the mass ratio of the effective components of the catalyst / promoter / adsorbent is Cu: Co: hydroxyl carbon nanotubes = 6: 3: 1, and the effective length of the membrane filament is 40cm. The packing density is 15%, and it is applied in the oil extraction wastewater treatment process that contains emulsified oil that is the main pollutant in the presence of surfactant in Example 2. The influent COD content is 800 ~ 840mg / L, and the SS is 232mg / L. TDS is 1.629g / L, pH is 7.95~8.59, and the dosage of ozone is 16.35 mg / min / m 2 .

[0063] Among them, the membrane element reactor is also filled with a commercial aluminum-based catalyst bed equivalent to 60% of the total volume of the reactor. The hydraulic retention time HRT is set to 1h. Such as Figure 4 Shown is the change graph of COD removal curve of product water with adsorption, catalytic membrane only and catalytic membrane plus catalyti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com