Waterproof impermeable concrete with self-repairing function and preparation method of waterproof impermeable concrete

A waterproof, impermeable, concrete technology, applied in the field of concrete, can solve the problems of high concrete brittleness, economic loss, personal safety threats, etc., and achieve the effects of increasing cross-linking density, increasing cross-linking density, and enhancing mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

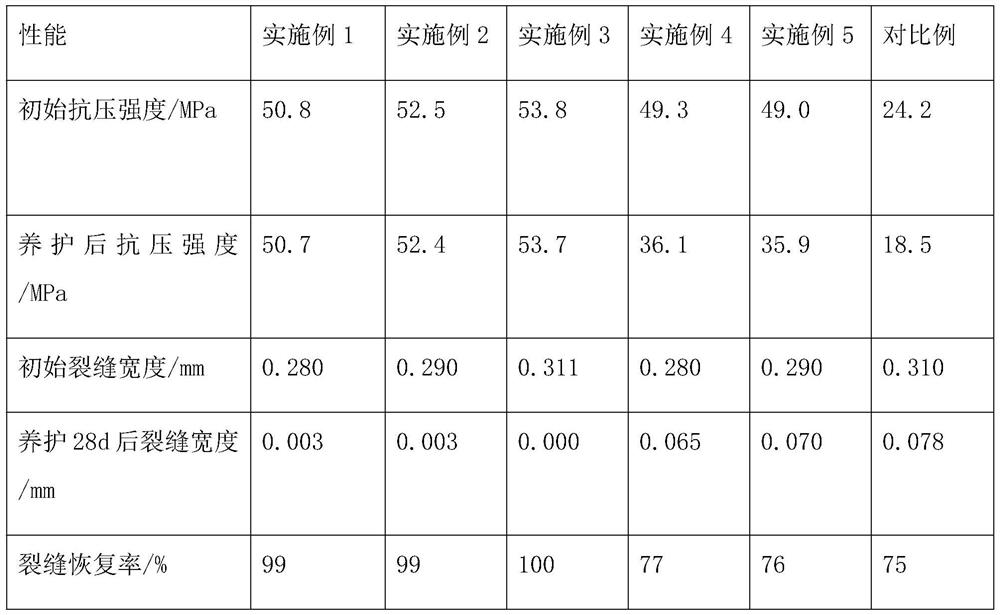

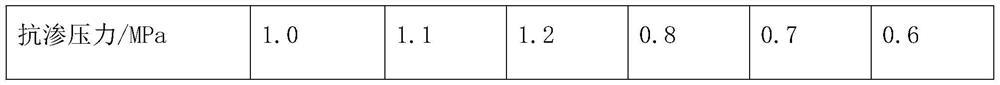

Embodiment 1

[0085] A waterproof and impermeable concrete with self-repairing function. The raw material components are as follows, in parts by weight, 300 parts of cement, 100 parts of sand and gravel, 80 parts of carboxylic acid water reducing agent, 70 parts of copper sulfate pentahydrate powder, repairing material 100 parts, 150 parts of modified adhesive resin.

[0086] The raw material components of the modified adhesive resin are as follows, in parts by weight, 50 parts of aminopropyl-terminated polydimethylsiloxane, 100 parts of rosin resin, 100 parts of polyurethane resin, isocyanophorone diisocyanate 30 parts, 80 parts of water-soluble polyrotaxane, 20 parts of dibutyltin dilaurate.

[0087]The repair material mainly includes bioremediation microspheres and supplementary repair capsules; the mass ratio of the bioremediation microspheres and supplementary repair capsules is 1:1; the surface of the repair material is also sprayed with a layer of calcium lactate and cement mixture; ...

Embodiment 2

[0112] A waterproof and impermeable concrete with self-repairing function. The raw material components are as follows, in parts by weight, 400 parts of cement, 130 parts of sand and gravel, 100 parts of carboxylic acid water reducing agent, 80 parts of copper sulfate pentahydrate powder, repairing material 110 parts, 170 parts of modified adhesive resin.

[0113] The raw material components of the modified adhesive resin are as follows, in parts by weight, 60 parts of aminopropyl-terminated polydimethylsiloxane, 150 parts of rosin resin, 150 parts of polyurethane resin, isocyanophorone diisocyanate 60 parts, 100 parts of water-soluble polyrotaxane, 30 parts of dibutyltin dilaurate.

[0114] The repair material mainly includes bioremediation microspheres and supplementary repair capsules; the mass ratio of the bioremediation microspheres and supplementary repair capsules is 2:1; the surface of the repair material is also sprayed with a layer of calcium lactate and cement mixtur...

Embodiment 3

[0139] A waterproof and impermeable concrete with self-repairing function. The raw material components are as follows, in parts by weight, 500 parts of cement, 150 parts of sand and gravel, 120 parts of carboxylic acid water reducing agent, 90 parts of copper sulfate pentahydrate powder, repairing material 120 parts, 200 parts of modified adhesive resin.

[0140] The raw material components of the modified adhesive resin are as follows, in parts by weight, 80 parts of aminopropyl-terminated polydimethylsiloxane, 200 parts of rosin resin, 200 parts of polyurethane resin, isocyanophorone diisocyanate 80 parts, 120 parts of water-soluble polyrotaxane, 40 parts of dibutyltin dilaurate.

[0141]The repair material mainly includes bioremediation microspheres and supplementary repair capsules; the mass ratio of the bioremediation microspheres and supplementary repair capsules is 3:1; the surface of the repair material is also sprayed with a layer of calcium lactate and cement mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impermeability pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com