Bionic light capture device N3/PT1/AAO film as well as preparation process and application thereof

A technology of N3-PT1 and preparation process, which is applied in the direction of photovoltaic power generation, electrolytic components, electrolytic organic production, etc., to achieve the effect of easy operation and realization, simple and novel preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

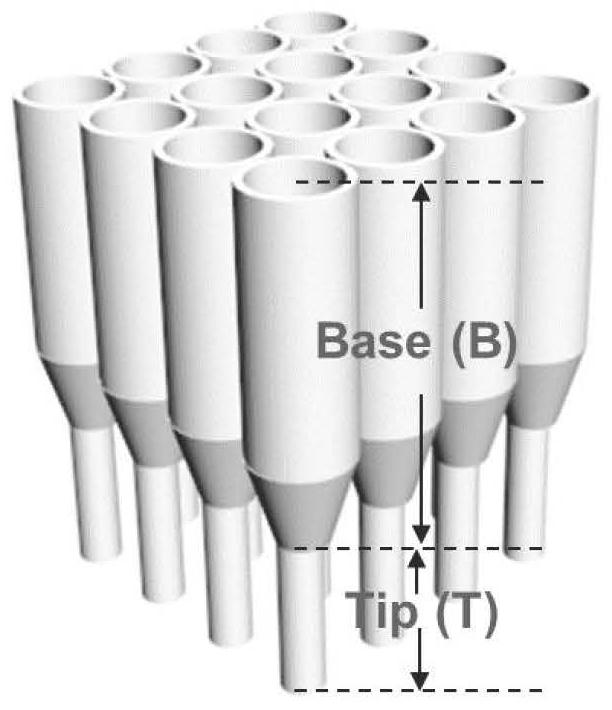

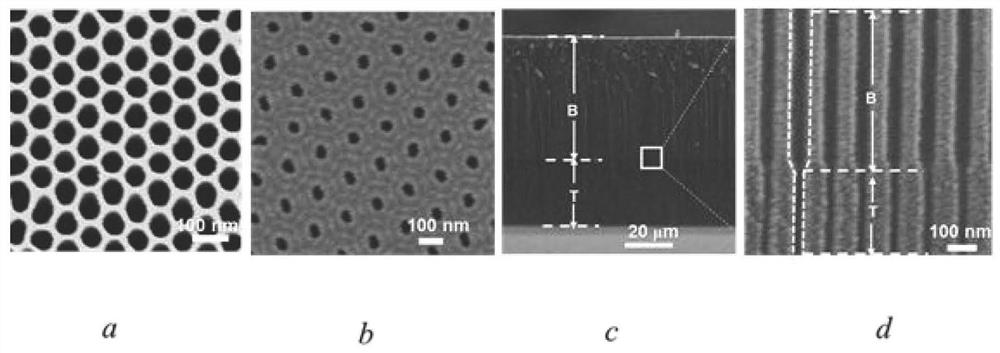

[0052] The substrate of PT1 and N3 electrostatic self-assembly used in the present invention is a funnel-shaped aluminum oxide nanochannel with asymmetric structure, which is prepared by three times of anodic oxidation combined with phosphoric acid pore expansion. The specific steps are as follows:

[0053] (1) Pretreatment: Firstly, the specification is made of high-purity aluminum (99.999% purity, 0.2mm thickness) with a size of 4.5×5.5cm 2 The aluminum sheet was pre-treated in detergent, acetone, absolute ethanol and high-purity water for 10 minutes respectively to clean the impurities on the aluminum oxide film.

[0054] (2) Electrochemical polishing: in perchloric acid (HClO 4 ) and ethanol (volume ratio 1:4) for electrochemical polishing, the polishing voltage is 17.0V, and the polishing time is 7 minutes, which makes the aluminum surface smoother and is conducive to the growth of the porous alumina layer.

[0055] (3) The first anodic oxidation: In a low-temperature an...

Embodiment 2

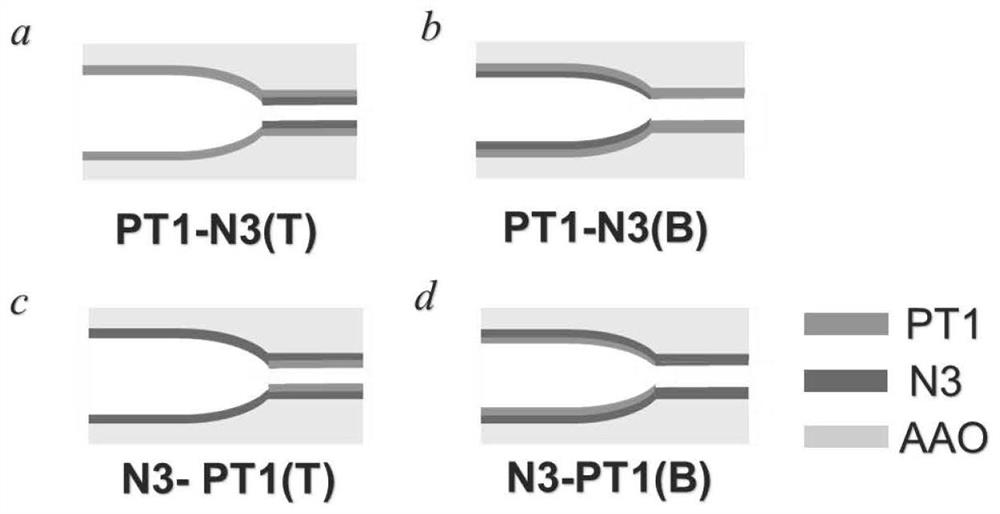

[0064] The preparation of a PT1-N3(T) bionic light harvesting device, the specific implementation steps are as follows:

[0065] (1) Using the preparation method provided in Example 1, a funnel-shaped aluminum oxide nanochannel with asymmetric structure was prepared by anodic oxidation method combined with phosphoric acid pore expansion method, washed and naturally air-dried, and set aside. The upper surface pore diameter of the funnel-shaped alumina nanochannel is 60±5nm, the lower surface pore diameter is 30±5nm, and the length is 80μm.

[0066] (2) The preparation solvent is a 1 mg / mL PT1 solution in DMF.

[0067] (3) Using the solvent evaporation method, PT1 was modified in the alumina nanochannel for 10 h, and the modification length was 80 μm to obtain PT1 functionalized AAO.

[0068] (5) The preparation solvent is 2mM N3 solution of ethanol and ethanol solution.

[0069] (6) The N3 solution was modified at the small hole end of the AAO nanochannel grafted with PT1 for...

Embodiment 3

[0074] The preparation of PT1-N3(B) bionic light harvesting system device, the specific implementation steps are as follows:

[0075] The other steps implemented in this example are the same as the preparation process in Example 2, except that the electrostatic assembly site is at the B end of the macropore.

[0076] Specifically, the AAO of the grafted PT1 in the case 2 (3) is placed in a self-made electrolyzer such as Figure 5 At the position of the connection 5c in the middle of the two tanks, inject the ethanol solution in the small hole side tank 5a of the AAO, and the N3 solution prepared in (4) in the large hole side tank 5b. Both sides control the length of grooming time at the same time. After modification for 4 hours, rinse with a large amount of ultrapure water and air-dry naturally to obtain a biomimetic photoresponse system device with a PT1-N3 (B) structure of the present invention, and the modified length of N3 is 54 μm.

[0077] PT1-N3(B) nanochannels are ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com