Preparation method and application of composite cathode integrating efficient in-situ electrosynthesis of hydrogen peroxide and catalytic performance

A composite cathode and hydrogen peroxide technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve problems such as unrecyclable, large demand, and large loss, and achieve structural advantages, catalytic highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Wash nickel foam (NF, 2.5*4cm) with acetone and ethanol repeatedly in order to remove grease and dry it for later use;

[0034] (2) adding a certain amount of nafion in absolute ethanol to obtain a nafion ethanol solution with a mass fraction of 0.2wt%;

[0035] (3) Add 0.1g carbon nanotubes (CNTs) in the 10ml nafion ethanol solution that step (2) obtains, ultrasonic 1h obtains the uniform carbon nanotube dispersion liquid, wherein the concentration of CNTs is 10mg / mL;

[0036] (4) Place the foamed nickel treated in step (1) in the carbon nanotube dispersion obtained in step (3), immerse and pull it several times and dry it, and place the electrode after drying with a mass fraction of 20%. Soak in PTFE aqueous solution for 2h to obtain foamed nickel metal electrodes loaded with carbon nanotubes, denoted as CNTs / NF; the unit mass of carbon nanotubes loaded on the foamed nickel is 5 mg / cm 2 .

[0037] (5) Weigh 3mmol of cobalt chloride (CoCl 2 ·6H 2 O) Dissolve in...

Embodiment 2

[0043] The difference between Embodiment 2 and Embodiment 1 lies in step (8). Take 30mg of cobalt-iron alloy carbon nanotubes and mix them with 20wt% PTFE (the mass ratio of cobalt-iron alloy carbon nanotubes to PTFE is 1:2), and the other steps are exactly the same.

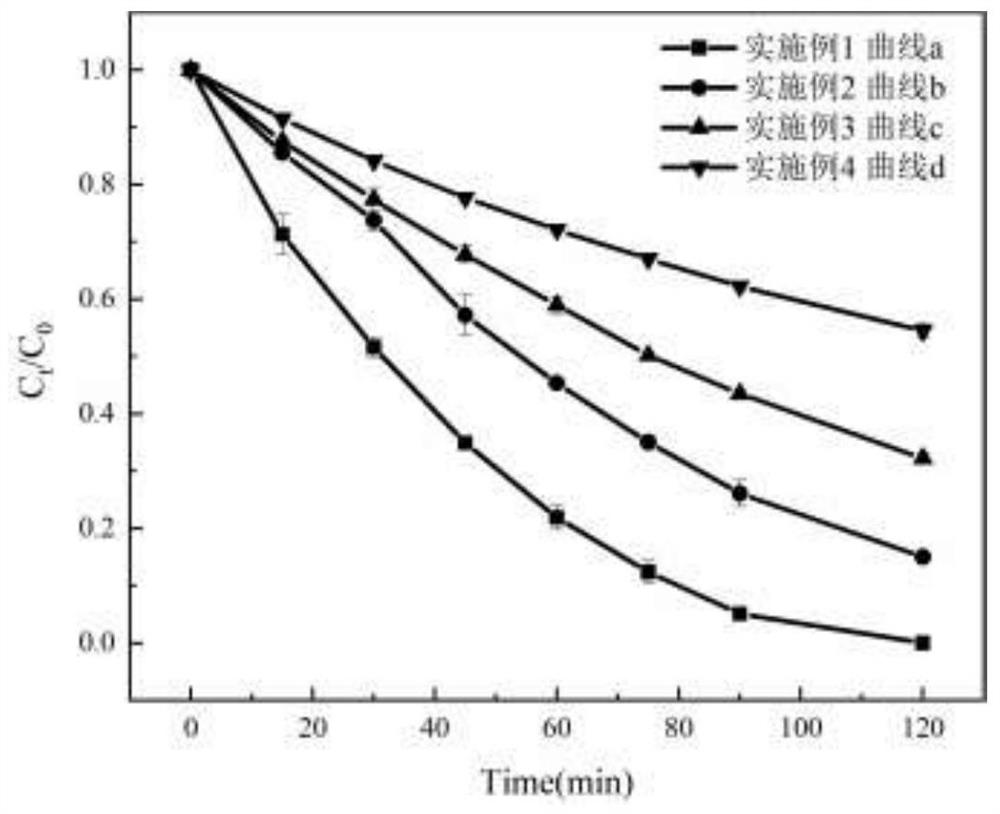

[0044] The electrode prepared above is used as the cathode, the platinum sheet (2*5cm) is used as the anode, the sodium sulfate of 0.05M is used as the electrolyte, the solution pH=3, I=90mA, the aeration flow rate is 0.6L / min, and atrazine ( ATZ) initial concentration is 10mg / L. After 120 minutes of reaction, the removal rate of atrazine was 85.0%. Such as figure 1 Shown in curve b.

Embodiment 3

[0046] The difference between Embodiment 3 and Embodiment 1 lies in step (6). Add 0.28g of CNTs to the mixed solution A, the concentration of CNTs in the mixed solution A is 7mg / mL, and keep stirring for 30min; prepare 50mmol / L potassium ferricyanide solution, add it dropwise to the mixed solution A, stir well Stand for aging for 24 hours, and then centrifuge and dry to obtain carbon nanotubes loaded with cobalt-iron Prussian blue analogues. The other steps are exactly the same.

[0047] The electrode prepared above is used as the cathode, the platinum sheet (2*5cm) is used as the anode, the sodium sulfate of 0.05M is used as the electrolyte, the solution pH=3, I=90mA, the aeration flow rate is 0.6L / min, and atrazine ( ATZ) initial concentration is 10mg / L. After 120 minutes of reaction, the removal rate of atrazine was 67.7%. Such as figure 1 Curve c is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com