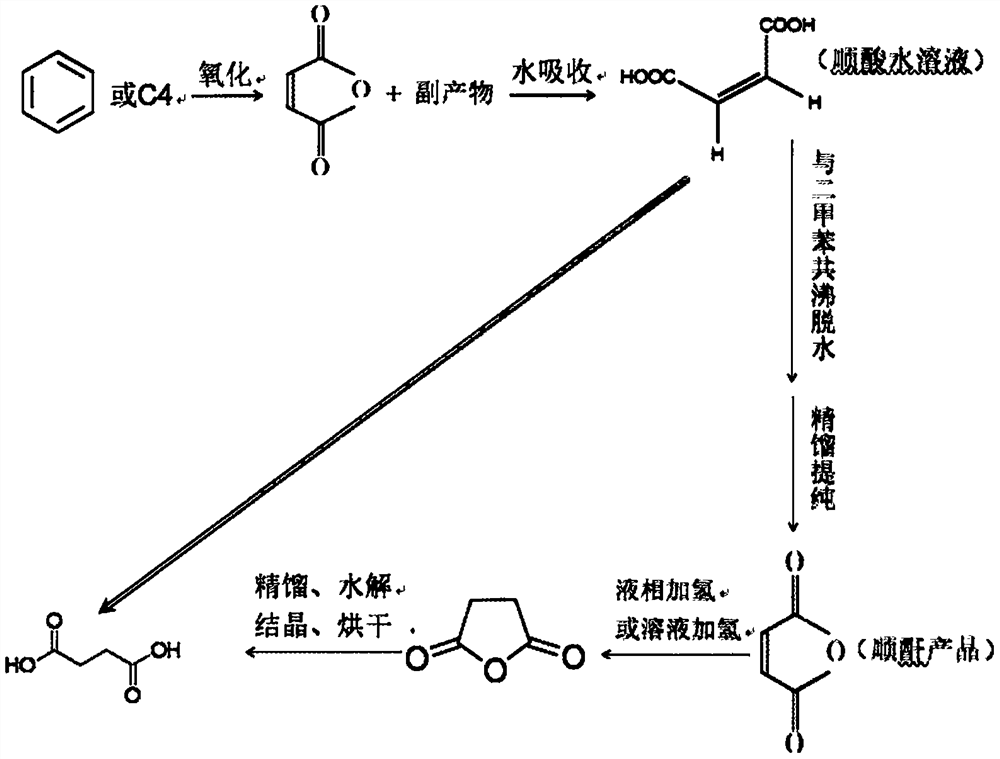

Method for synthesizing succinic acid through low-cost continuous water-phase catalytic hydrogenation

A technology for catalytic hydrogenation and succinic acid, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, catalytic reactions, etc., can solve the problem of high cost of succinic acid synthesis process, achieve cheap raw materials, avoid side reactions, No effect of three wastes pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The catalyst described in this embodiment is prepared by using silicon carbide as a carrier and ruthenium as an active component by impregnation method, which specifically includes the following steps:

[0034] (1) With ruthenium as the active component, with zirconia as auxiliary agent, prepare impregnation solution with the precursor of ruthenium (ruthenium trichloride) and the precursor of zirconia (zirconium nitrate), control the mass concentration of ruthenium chloride as 2wt%, the mass concentration of the control zirconium salt is 8.1wt%;

[0035] (2) Using 10wt% nitric acid to pretreat the silicon carbide carrier at 40° C. for 12 hours to obtain a pretreated carrier;

[0036] (3) Immerse the obtained carrier in the impregnating solution prepared in step (1) by impregnation method to carry out normal temperature loading, after conventional drying and roasting at 400°C, the active component ruthenium content is 3wt%, and the auxiliary agent zirconia content is 7wt...

Embodiment 2

[0039] The catalyst described in this example is prepared by using activated carbon as a carrier and copper as an active component by an impregnation method, which specifically includes the following steps:

[0040] (1) take copper as active component, take sodium nitrite as auxiliary agent, prepare dipping solution with copper precursor (copper nitrate) and sodium nitrite, control the mass concentration of copper nitrate to be 11.8wt%, control sodium nitrite The mass concentration is 0.9wt%;

[0041] (2) Using 30wt% sulfuric acid to pretreat the activated carbon carrier at 90°C for 0.5h to obtain a pretreated carrier;

[0042] (3) Use the impregnation method to impregnate the obtained carrier in the impregnation solution prepared in step (1) to carry out normal temperature loading, and through conventional drying and roasting in nitrogen at 400°C, the active component copper content is 20wt%, and the additive sodium nitrite Catalyst at 4.5% by weight.

[0043] As the flow c...

Embodiment 3

[0045] The catalyst described in this example is prepared with α-alumina as the carrier and palladium as the active component by impregnation method, which specifically includes the following steps:

[0046] (1) Taking palladium as an active component, preparing an impregnating solution with a palladium precursor (palladium chloride), controlling the mass concentration of palladium chloride to be 0.5wt%;

[0047] (2) Pretreating the α-alumina carrier at 20° C. for 5 hours with 5 wt % hydrofluoric acid to obtain a pretreated carrier;

[0048] (3) Immerse the obtained carrier in the impregnation solution prepared in step (1) by impregnation method to carry out normal temperature loading, conventional drying and roasting at 400° C. to obtain a catalyst with an active component palladium content of 0.1 wt%.

[0049] As the flow chart shown in the accompanying drawing, the method for synthesizing succinic acid by aqueous catalytic hydrogenation described in this example uses 5 wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com