A cesium-doped vanadium potassium fluorophosphate/carbon positive electrode material and its preparation method and application

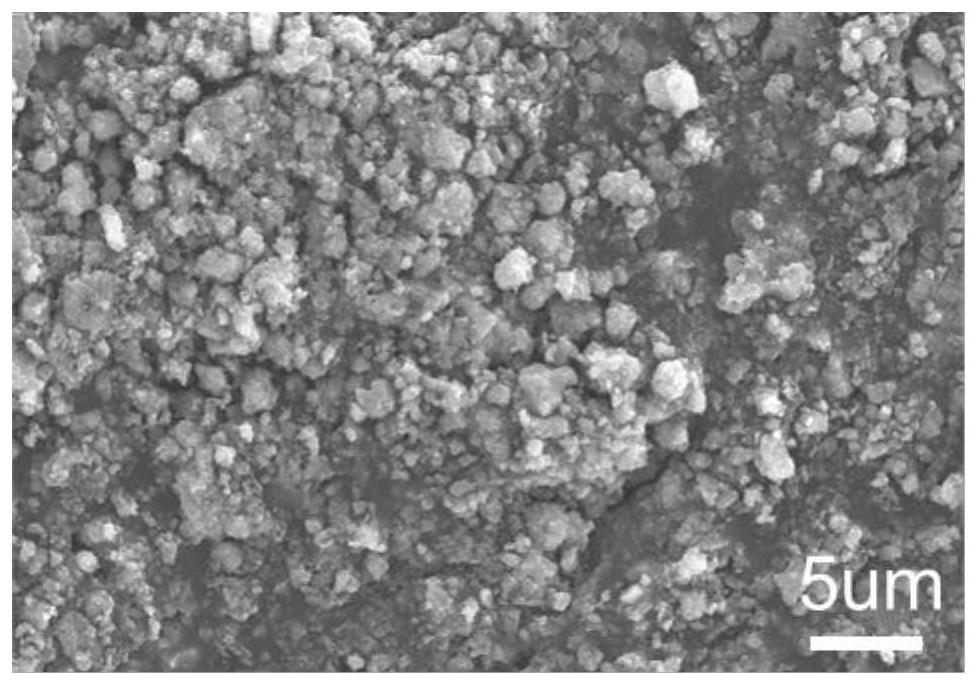

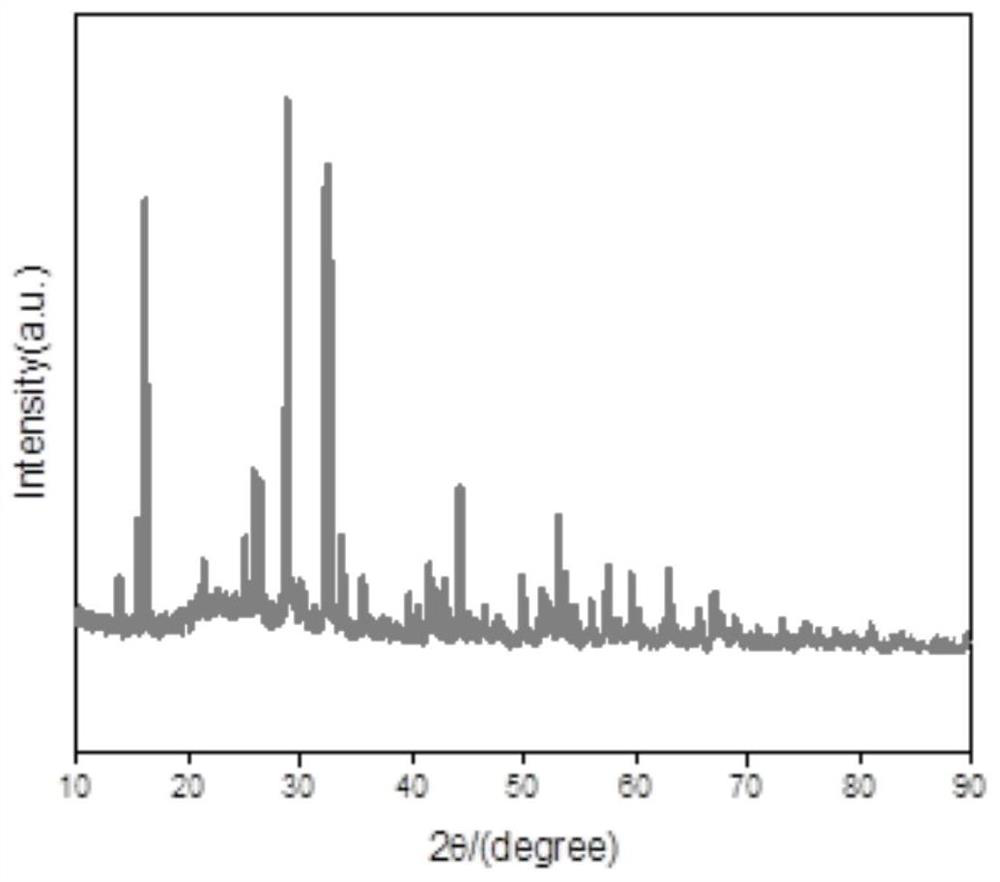

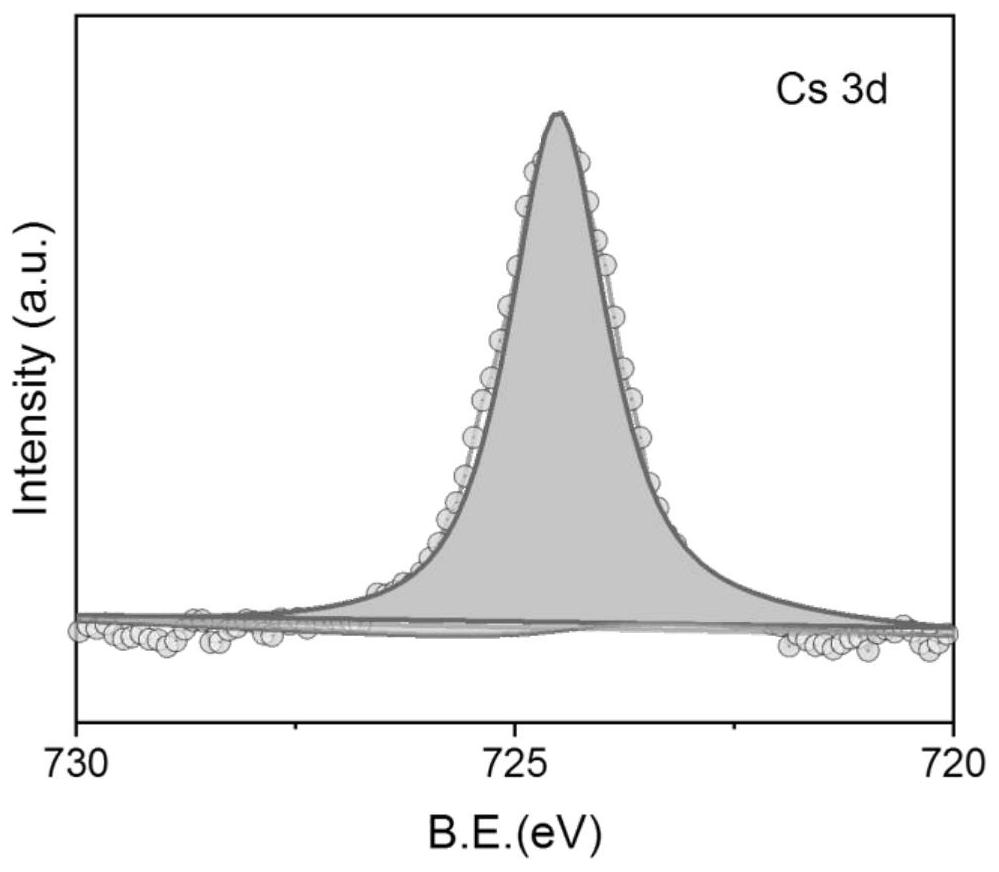

A technology of vanadium potassium fluorophosphate and cesium doping, which is applied in the field of cesium-doped vanadium potassium fluorophosphate/carbon cathode materials and its preparation, can solve the problems of poor electronic conductivity and ion conductivity, and achieve cycle performance enhancement and reduction Effect of transition barrier and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The anode material of the present embodiment cesium substituted vanadium potassium fluorophosphate type potassium battery, its expression is: K 0.98 Cs 0.02 VPO 4 F / C.

[0042]Weigh 0.1 mol of vanadium pentoxide, 0.2 mol of diammonium hydrogen phosphate, and 0.25 mol of acetylene black into the ball mill jar, and add 15ml of water, start the planetary ball mill, and ball mill at 600r / min for 12 hours to mix the mixture evenly , and the mixture was dried in an oven at 100°C for 12h and ground into tablets, the vanadium phosphate precursor was transferred to a tube furnace, heated to 750°C at a heating rate of 4°C / min under an argon atmosphere, and kept at a constant temperature for 4h After cooling naturally to room temperature, the vanadium phosphate / carbon composite material can be obtained. The obtained vanadium phosphate / carbon composite material and 0.004mol cesium fluoride, 0.196mol potassium chloride, and 0.196mol ammonium fluoride are transferred to a ball mil...

Embodiment 2

[0044] The anode material of the present embodiment cesium substituted vanadium potassium fluorophosphate type potassium battery, its expression is: K 0.95 Cs 0.05 VPO 4 F / C.

[0045] Weigh 0.1mol of vanadium pentoxide, 0.2mol of ammonium phosphate, and 0.22mol of Ketjen black into the ball mill jar, and add 15ml of ethanol, start the planetary ball mill, and at 400r / min, ball mill for 24h to mix the mixture evenly, The mixture was dried in an oven at 80°C for 20 hours and ground into tablets. The vanadium phosphate precursor was transferred to a tube furnace and heated to 700°C at a heating rate of 3°C / min under an argon atmosphere. After constant temperature for 6 hours Cool naturally to room temperature to obtain vanadium phosphate / carbon composite material. Transfer the obtained vanadium phosphate / carbon composite material and 0.01mol cesium chloride, 0.1mol potassium fluoride, and 0.09mol ammonium fluoride to a ball mill tank, start the planetary ball mill, and mix the...

Embodiment 3

[0047] The anode material of the present embodiment cesium substituted vanadium potassium fluorophosphate type potassium battery, its expression is: K 0.92 Cs 0.08 VPO 4 F / C.

[0048] Weigh 0.2 mol of ammonium metavanadate and 0.2 mol of ammonium dihydrogen phosphate, and add 0.23 mol of Ketjen black into the ball mill jar, and add 15 ml of ethanol, start the planetary ball mill, and mix the mixture by ball milling for 24 hours at 400r / min uniform, and the mixture was dried in an oven at 80°C for 12h and ground into tablets, the vanadium phosphate precursor was transferred to a tube furnace, and heated to 750°C at a heating rate of 2°C / min under an argon atmosphere. After 4 hours, it was naturally cooled to room temperature to obtain the vanadium phosphate / carbon composite material. Transfer the obtained vanadium phosphate / carbon composite material, 0.016mol cesium fluoride, and 0.184mol potassium fluoride to a ball mill jar, start the planetary ball mill, and mix the mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com