Modified porous copper-nickel alloy plate and preparation method and application thereof

A porous copper and nickel alloy technology, applied in the field of materials, can solve the problems of large equipment loss, complex supporting devices, low efficiency, etc., achieve high degradation rate and degradation efficiency, improve catalytic degradation effect, and improve degradation treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a modified porous copper-nickel alloy plate, comprising the following steps:

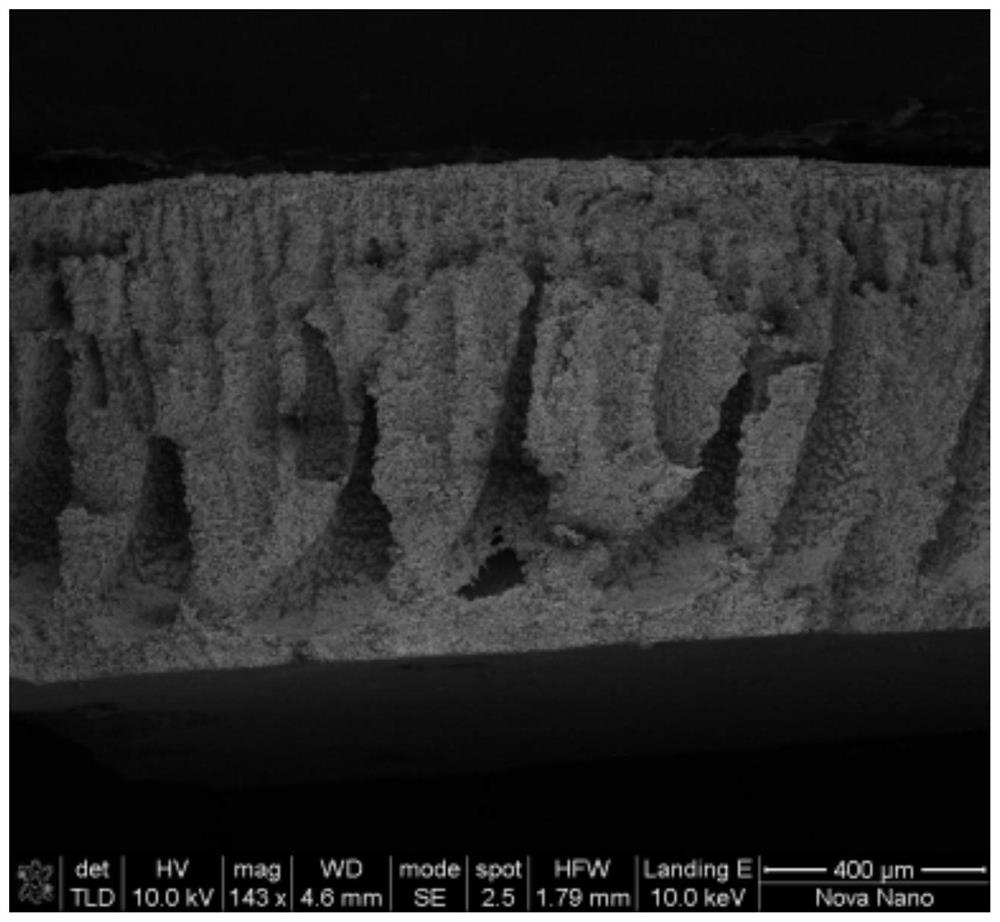

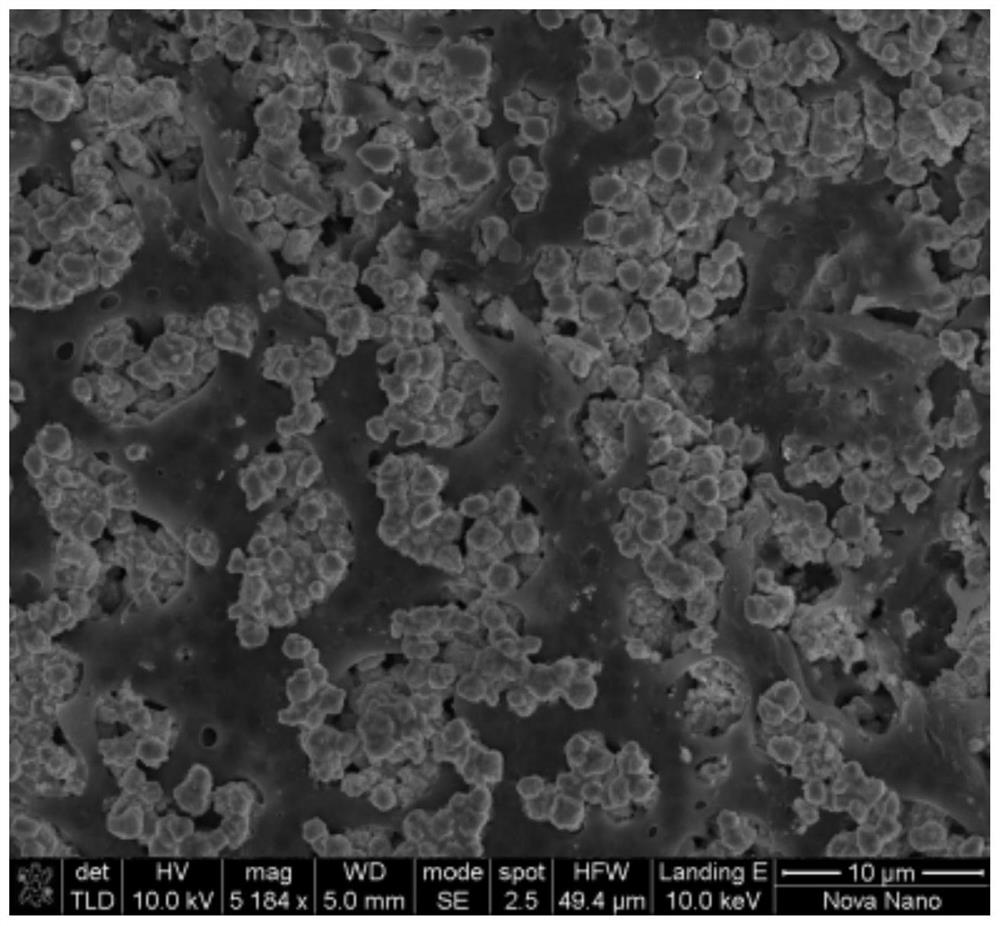

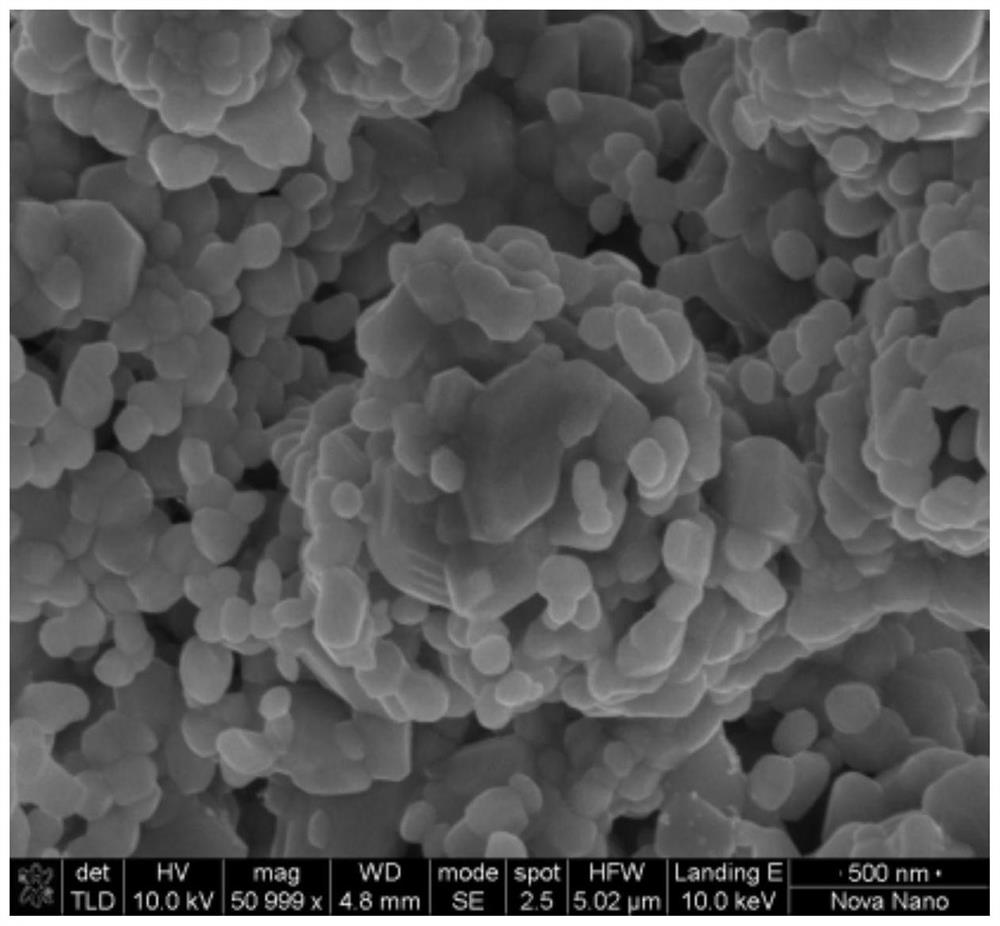

[0038]Step 1, mix polysulfone, pyrrolidone (pvp), copper powder (particle size 1000 μm), nickel powder (particle size 500nm) and N-methylpyrrolidone (NMP) to form a metal powder slurry with a certain viscosity, wherein, in In the metal powder slurry, the mass percent of copper powder is 63%, the mass percent of nickel powder is 5%, the mass percent of polysulfone is 5.12%, the mass percent of described viscosity regulator is 1.45%, the mass percent of described organic solvent The percentage is 25.43%; then put the metal powder slurry in a vacuum drying oven to vacuum for 4 hours to remove the air bubbles in the metal powder slurry, and then scrape the metal powder slurry on the glass plate, the thickness is controlled between 0.2 ~ 2mm , and then quickly immersed in water for 8 hours to prepare the precursor of the porous copper-nickel alloy plate. Its electron micros...

Embodiment 2

[0043] Change the heating temperature of Step 3 in Example 1 to 500°C, and follow the same steps and conditions as in Example 1 to prepare a porous copper-nickel alloy plate with amorphous carbon grown on the surface in situ as Experiment Group 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com