Modified graphene modified cement-based composite material and preparation method thereof

A graphene modification and composite material technology, applied in the field of building materials, can solve the problems of difficult dispersion, uneven distribution of force, easy agglomeration, etc., and achieve the effects of improving compressive strength, easy access to raw materials, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the modified multilayer graphene is:

[0030] (a) Weigh 4g multilayer graphene, place it in 400mL of 0.05mol / L sodium chlorate, 0.05mol / L sulfuric acid and 0.05mol / L hydrogen peroxide mixed solution, heat the solution to 35°C and stir Oxidation was performed for 15 minutes, the supernatant liquid was poured off after standing, the solid matter in the lower layer was washed with absolute ethanol and deionized water, and the obtained solid matter was dried at 60°C to obtain carboxyl-modified multilayer graphene;

[0031] (b) Add the carboxy-modified multi-layer graphene of step (a) to 0.02g / L dodecyltrimethylammonium bromide solution, heat to 50°C and stir evenly, then slowly add 0.3g poly Amide-amine dendrimers, reflux reaction for 4h, during the reaction, the solution was stirred and ultrasonic treatment was applied;

[0032] (c) After the reaction, the reaction solution is centrifugally settled, washed with absolute ethanol and deionized wate...

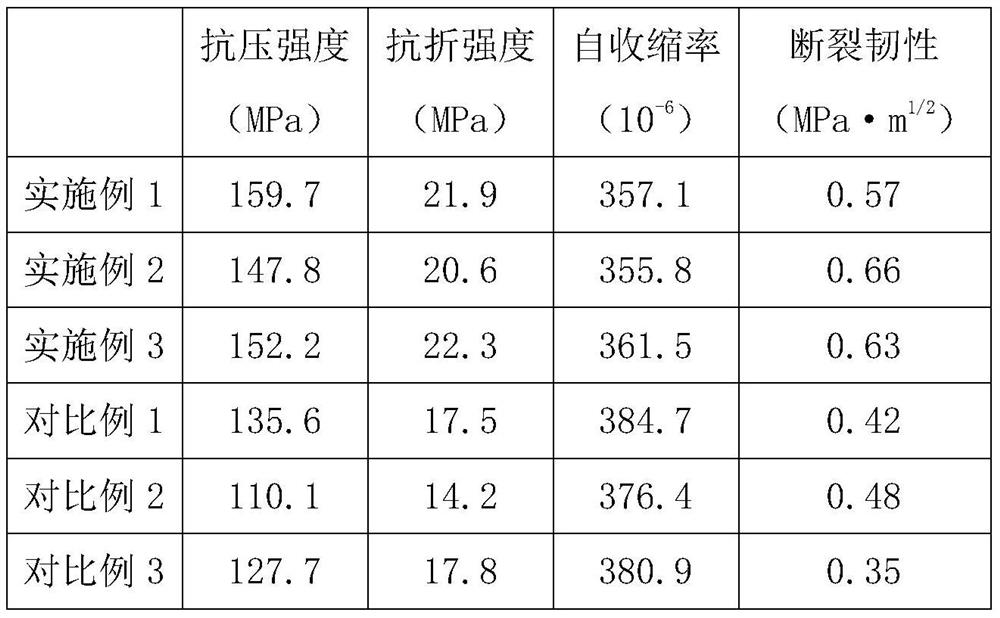

Embodiment 1

[0037] A modified graphene-modified cement-based composite material, comprising 30 parts of sulfoaluminate cement, 50 parts of quartz sand, 10 parts of fly ash, 5 parts of reinforcing fiber, and 3 parts of modified multilayer graphite in parts by weight olefin, 1 part of naphthalene-based high-efficiency water reducer, 1 part of defoamer, 10 parts of water; the reinforcing fiber is steel fiber, and the aspect ratio of the reinforcing fiber is 20:1. The solid content of the naphthalene-based high-efficiency water reducer is 30%, and the water reducing rate is between 30%. The defoamer is a phosphate defoamer.

[0038] The preparation method of described cement-based composite material, comprises the steps:

[0039](1) Add the modified multilayer graphene into water under stirring and ultrasonic treatment conditions, and finally obtain the modified multilayer graphene that can be uniformly and stably dispersed in water, and then add naphthalene-based high-efficiency water reduc...

Embodiment 2

[0043] A modified graphene-modified cement-based composite material, comprising 50 parts of Portland cement, 80 parts of quartz sand, 20 parts of fly ash, 10 parts of reinforced fiber, and 7 parts of modified multilayer graphene in parts by weight , 3 parts of naphthalene-based superplasticizer, 2 parts of defoamer, 30 parts of water; the reinforcing fiber is glass fiber, and the aspect ratio of the reinforcing fiber is 30:1. The solid content of the naphthalene-based high-efficiency water reducer is 40%, and the water reducing rate is between 50%. The defoamer is a silicone defoamer.

[0044] The preparation method of described cement-based composite material, comprises the steps:

[0045] (1) Add the modified multilayer graphene into water under stirring and ultrasonic treatment conditions, and finally obtain the modified multilayer graphene that can be uniformly and stably dispersed in water, and then add naphthalene-based high-efficiency water reducer and defoamer respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com