Preparation method of piezoelectric enhanced microfluidic photoelectrochemical sensor

A photoelectrochemical and microfluidic technology, applied in chemical instruments and methods, electrochemical variables of materials, scientific instruments, etc., can solve the problems of difficult to realize full automation, narrow linear range, low sensitivity, etc., to improve signal stability and Reproducibility, realization of sensitive detection, effect of accelerating electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

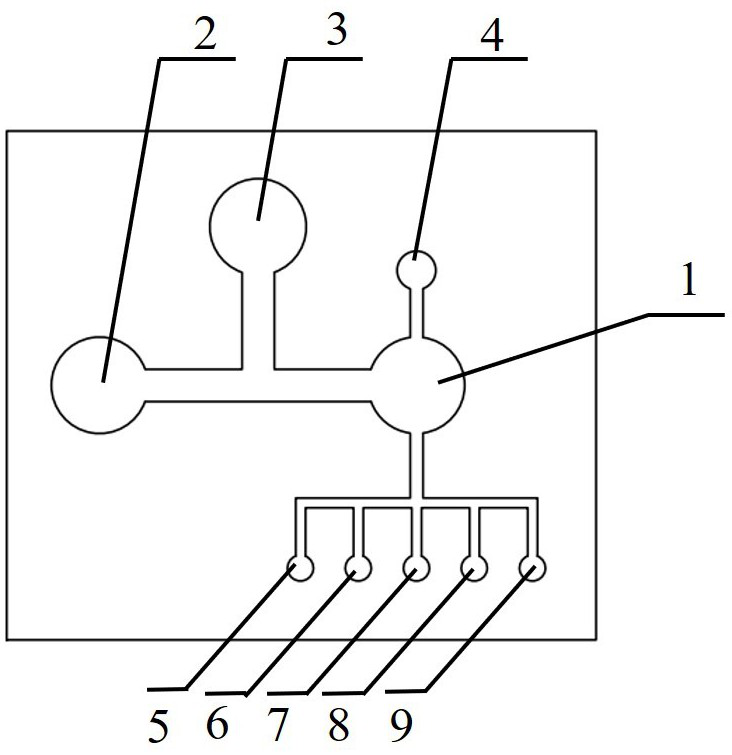

[0033] A method for preparing a piezoelectric-enhanced nano-array microfluidic photoelectrochemical sensor for the detection of sepsis markers, the preparation steps are as follows:

[0034] (1) Design and draw microfluidic channel graphics with computer design software AUTOCAD;

[0035] (2) Use the designed pattern to draw the mask, and process the microfluidic polydimethylsiloxane PDMS chip with standard soft lithography technology;

[0036] (3) The 5 cm × 4 cm ITO conductive glass was ultrasonically cleaned with acetone, ethanol and ultrapure water for 30 minutes, and then dried with nitrogen, and the cleaned ITO conductive glass was etched in sequence, and the Ag / AgCI slurry The bottom plate of the micro working electrode 1 and the micro reference electrode 2 is obtained by screen printing;

[0037] (4) Drop 20 µL of 0.1 mol / L zinc nitrate and 0.1 mol / L cyclohexamethylenetetramine mixed solution on the micro-working electrode, dry it at room temperature and anneal at 300 ...

Embodiment 2

[0044] A method for preparing a piezoelectric-enhanced nano-array microfluidic photoelectrochemical sensor for the detection of sepsis markers, the preparation steps are as follows:

[0045] (1) Design and draw microfluidic channel graphics with computer design software AUTOCAD;

[0046] (2) Use the designed pattern to draw the mask, and process the microfluidic polydimethylsiloxane PDMS chip with standard soft lithography technology;

[0047] (3) The 5 cm × 4 cm ITO conductive glass was ultrasonically cleaned with acetone, ethanol and ultrapure water for 30 minutes, and then dried with nitrogen, and the cleaned ITO conductive glass was etched in sequence, and the Ag / AgCI slurry The bottom plate of the micro working electrode 1 and the micro reference electrode 2 is obtained by screen printing;

[0048] (4) Drop 20 µL of 0.5 mol / L zinc nitrate and 0.5 mol / L cyclohexamethylenetetramine mixed solution on the micro-working electrode, dry it at room temperature and anneal at 300 ...

Embodiment 3

[0055] A method for preparing a piezoelectric-enhanced nano-array microfluidic photoelectrochemical sensor for the detection of sepsis markers, the preparation steps are as follows:

[0056] (1) Design and draw microfluidic channel graphics with computer design software AUTOCAD;

[0057] (2) Use the designed pattern to draw the mask, and process the microfluidic polydimethylsiloxane PDMS chip with standard soft lithography technology;

[0058] (3) The 5 cm × 4 cm ITO conductive glass was ultrasonically cleaned with acetone, ethanol and ultrapure water for 30 minutes, and then dried with nitrogen, and the cleaned ITO conductive glass was etched in sequence, and the Ag / AgCI slurry The bottom plate of the micro working electrode 1 and the micro reference electrode 2 is obtained by screen printing;

[0059] (4) Drop 20 µL of 0.5 mol / L zinc nitrate and 0.5 mol / L cyclohexamethylenetetramine mixed solution on the micro-working electrode, dry it at room temperature and anneal at 300 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com