A kind of regeneration method of deactivated propane dehydrogenation catalyst

A dehydrogenation catalyst and propane dehydrogenation technology, applied in the direction of catalyst regeneration/reactivation, catalyst, molecular sieve catalyst, etc., can solve the problems of Pt active component aggregation and growth, dehydrogenation performance decline, catalyst deactivation, etc., and achieve recovery Catalyst performance, sintering reduction, agglomeration reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0077] According to a preferred embodiment of the present invention, preferably, the content of the active component is 0.1-0.6%.

[0078] According to a preferred embodiment of the present invention, preferably, the content of the transition metal is 0.1-2%.

[0079] According to a preferred embodiment of the present invention, preferably, the content of alkali metal is 0.1-1%.

[0080] According to a preferred embodiment of the present invention, preferably, the active component, the alkali metal and the transition metal are supported on the carrier by a method of vacuum impregnation.

[0081] According to a preferred embodiment of the present invention, preferably the active component is Pt and / or Pd.

[0082] According to a preferred embodiment of the present invention, the alkali metal is one or more of Li, Na, K and Cs, preferably Na and / or K.

[0083] According to a preferred embodiment of the present invention, the transition metal is one or more of Sn, Fe and Zn.

...

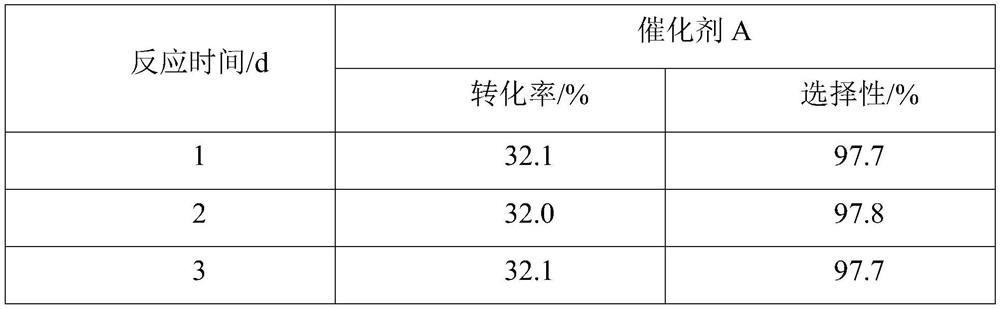

Embodiment 1

[0145] (1) Synthesis of molecular sieve: dissolve 180.25 grams of silica sol with a solid content of 20% in 180 grams of deionized water, then add 72.89 grams of cetyltrimethylammonium bromide (hereinafter referred to as CTABr) and 6.66 grams of aluminum sulfate, The above sample was stirred at room temperature for 3 hours to form a homogeneous gel. The substance in the gel is calculated in molar ratio: SiO 2 :Al 2 O 3 :CTABr:H 2 O=300:1:20:1000. The above sample was transferred into an autoclave, crystallized at 170°C for 60 hours, the crystallization product was filtered and washed to neutrality, dried at 120°C, and calcined at 500°C for 4 hours to obtain MFI type molecular sieve raw powder. The prepared sample was added to a 1.0% mass concentration of sodium hydroxide solution (the following are all mass concentrations), and the temperature was maintained at 70° C. for 5 hours. The sample treated with alkali solution was filtered, dried and roasted for later use, and t...

Embodiment 2

[0151] Dehydrogenation catalyst sample B after deactivation of dehydrogenation reaction 2 The temperature was lowered to 400°C, and CO was introduced at a flow rate of 20ml / min. 2 gas, regeneration time for 10 hours; then continue to cool down to 300 ° C, and treat with oxygen and water vapor for 2 hours, wherein the molar ratio of oxygen: water vapor is 1:3; after the above steps are completed, use 50ml / min flow rate Nitrogen blows out oxygen and water vapor, the temperature continues to decrease to 100°C, and ethylene glycol is introduced into the catalyst at a rate of 1ml / min for 3 hours; then, under nitrogen protection, the temperature is raised to 450°C, and pure H is introduced 2 For reducing gas, the treatment time is 0.5 hours. The regenerated catalyst is denoted as R1, the evaluation method is the same as that of Example 1, and the results after 3 days of reaction are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com