ASA/PC 3D printing wire rod with low VOC release and preparation method thereof

A technology for printing wire rods and ASA resins, applied in the direction of additive processing, etc., can solve the problems of ASA/PC materials that have not been reported in the application, and do not involve the amount of VOC release, so as to reduce the source of VOC release, smooth printing performance and stable size The effect of good sex and smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

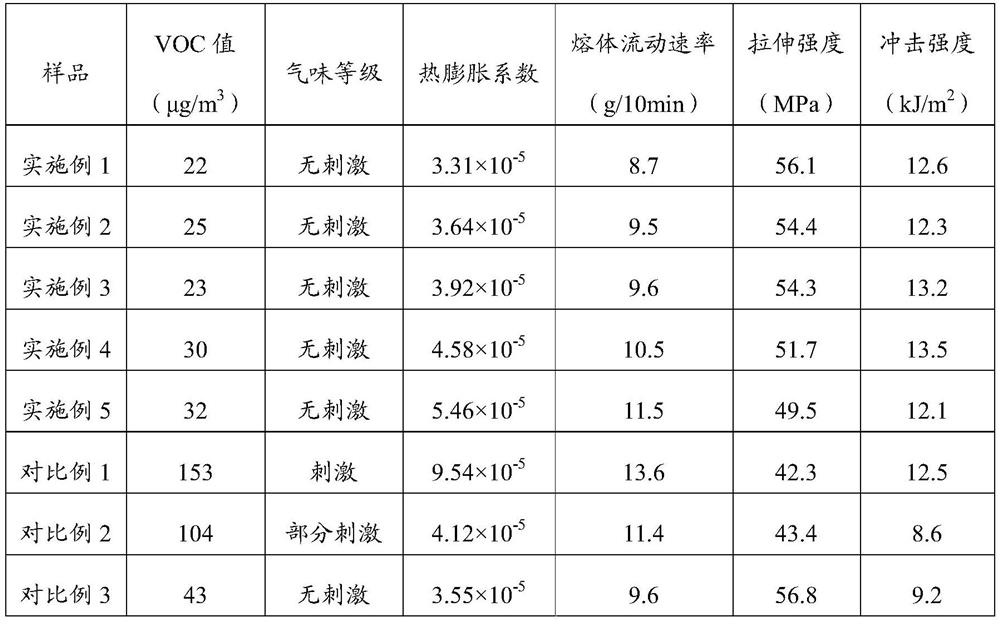

Examples

Embodiment 1

[0033] A low-VOC release ASA / PC 3D printing wire, the components are calculated by weight percentage: ASA 50%, PC 30%, modified porous calcium silicate 15%, monobutyltin oxide 0.5%, zinc stearate 2 %, antioxidant 1010 {tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester} 0.5% and paraffin wax 2%.

[0034] A preparation method for ASA / PC 3D printing filaments released by low VOC, comprising the following steps:

[0035] (1) Preparation steps of modified porous calcium silicate:

[0036] A. Put 25g of porous calcium silicate into 1L of deionized water for ultrasonic dispersion for 1h, and add 8ml of acetic acid under stirring;

[0037] B. Then add 2g of chitosan, react at room temperature for 2h, then filter, wash until neutral and dry to obtain modified porous calcium silicate.

[0038] (2) ASA, PC, modified porous calcium silicate, monobutyl tin oxide, zinc stearate, and antioxidant 1010 were vacuum-dried respectively, and the dried components an...

Embodiment 2

[0046] A low VOC release ASA / PC 3D printing wire, the components are calculated by weight percentage: ASA 53%, PC 28%, modified porous calcium silicate 14%, tributyltin chloride 0.3%, calcium stearate 2%, antioxidant CA[1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane] 0.7% and silicone oil 2%.

[0047] A preparation method for ASA / PC 3D printing filaments released by low VOC, comprising the following steps:

[0048] (1) Preparation steps of modified porous calcium silicate:

[0049] A. Put 35g of porous calcium silicate into 1L of deionized water for ultrasonic dispersion for 0.5h, and add 10ml of acetic acid under stirring;

[0050] B. Then add 5g of chitosan, react at room temperature for 3h, then filter, wash to neutral and dry to obtain modified porous calcium silicate.

[0051] (2) ASA, PC, modified porous calcium silicate, tributyltin chloride, calcium stearate and antioxidant CA are vacuum-dried respectively, and the components and silicone oil after drying ar...

Embodiment 3

[0055] A low VOC release ASA / PC 3D printing wire, the components are calculated by weight percentage: ASA 63%, PC 21%, modified porous calcium silicate 12%, butyl tin trichloride 0.6%, magnesium stearate 1.3%, antioxidant DNP [N,N'-di(β-naphthyl)-p-phenylenediamine)] 0.6% and stearic acid 1.5%.

[0056] A preparation method for ASA / PC 3D printing filaments released by low VOC, comprising the following steps:

[0057] (1) Preparation steps of modified porous calcium silicate:

[0058] A. Put 20g of porous calcium silicate into 1L of deionized water for ultrasonic dispersion for 2 hours, and add 5ml of acetic acid under stirring;

[0059] B. Then add 1.5g of chitosan, react at room temperature for 2h, then filter, wash until neutral and dry to obtain modified porous calcium silicate.

[0060] (2) ASA, PC, modified porous calcium silicate, butyl tin trichloride, magnesium stearate and antioxidant DNP are vacuum-dried respectively, and each component after drying and stearic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com