Comprehensive recycling method of organic phosphine production by-product phosphorus-containing composite salt

A technology of compound salt and hydrochloric acid, applied in the field of comprehensive utilization of phosphorus-containing compound salt, can solve problems such as failure to meet standard requirements, program errors, pollution, etc., and achieve the effect of solving comprehensive utilization problems, low recovery cost, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] This example provides a kind of recycling method of phosphorus-containing compound salt, implements as follows:

[0087] S1. Weigh 1000 grams of the same batch of phosphorus-containing compound salt as the test sample, control the temperature, add in batches to 2100 grams of 4% hydrochloric acid solution containing 0.5 grams of azobisisobutyronitrile, and simultaneously add cyclohexene 52 gram, keep system temperature about 80-85 degrees centigrade in the adding process, obtain the first mixture, and the aforementioned reaction equation involved is as follows:

[0088]

[0089] S2. Pass 105 grams of hydrogen chloride into the first mixture, continue to stir for 30 minutes, rise to 80 degrees Celsius, keep warm for 1 hour, filter, filter the cake with 650 grams of 20% hydrochloric acid, wash it, filter and dry to obtain 297.5 grams of sodium chloride Detecting sodium ion calibration sodium chloride content with ion chromatography is 99.56%, and ammonium molybdate spec...

Embodiment 2

[0093] This example provides a kind of recycling method of phosphorus-containing compound salt, implements as follows:

[0094] S1. Weigh 1000 grams of the same batch of phosphorus-containing compound salt as the test sample, control the temperature, and add it to 2100 grams of 3.5% hydrochloric acid solution in batches. When the phosphorus-containing compound salt is completely added, add 1 gram of di-tert-butyl peroxide , feed ethylene to keep the system pressure at 0.05MPa, until the system pressure does not change, continue to stir for 30 minutes, emit residual ethylene, and obtain the first mixture, the aforementioned reaction equation involved is as follows:

[0095]

[0096] S2. Pass 105 grams of hydrogen chloride into the first mixture, continue to stir for 30 minutes, rise to 75 degrees Celsius, keep warm for 1.5 hours, filter, filter the cake with 650 grams of 20% hydrochloric acid, wash it, filter and dry to obtain 296.7 grams of sodium chloride , it is 99.46% to...

Embodiment 3

[0101] The methylcyclohexylphosphinic acid (compound I-1) that embodiment 1 obtains is dissolved in 500 grams of water, adds sodium hydroxide to neutralize to neutrality, adds the solution that 66 grams of aluminum sulfate octadecahydrate is dissolved in 300 grams of water , stirred and reacted for 2 hours, filtered, washed with water, and dried to obtain 98.5 grams of aluminum methylcyclohexylphosphinate flame retardant, with a yield of 98.3%. The reaction equation is as follows:

[0102]

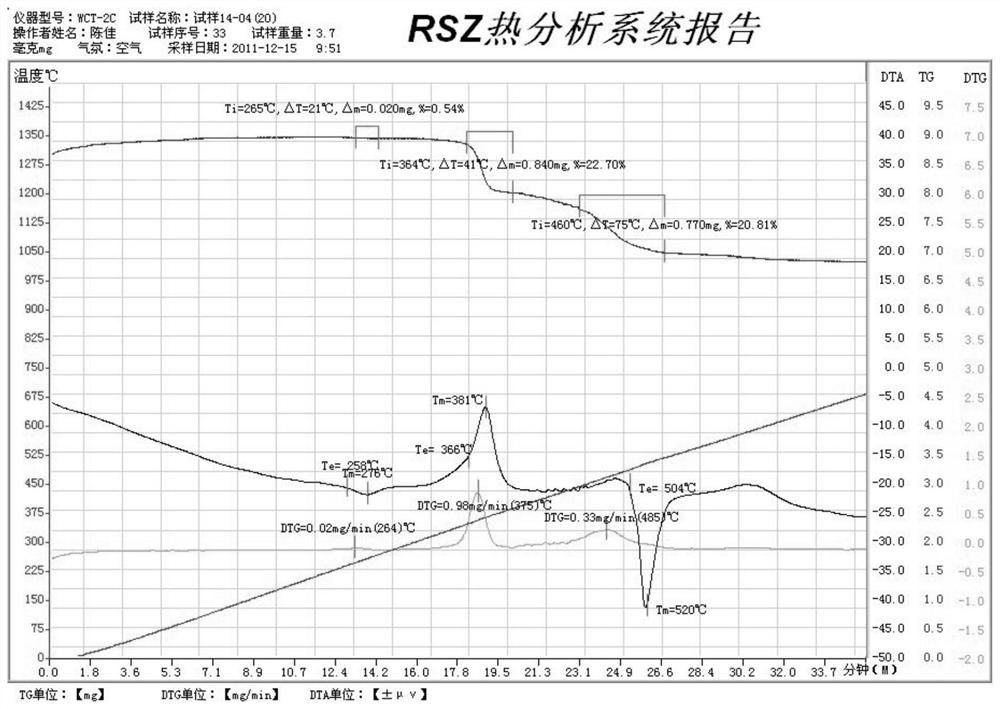

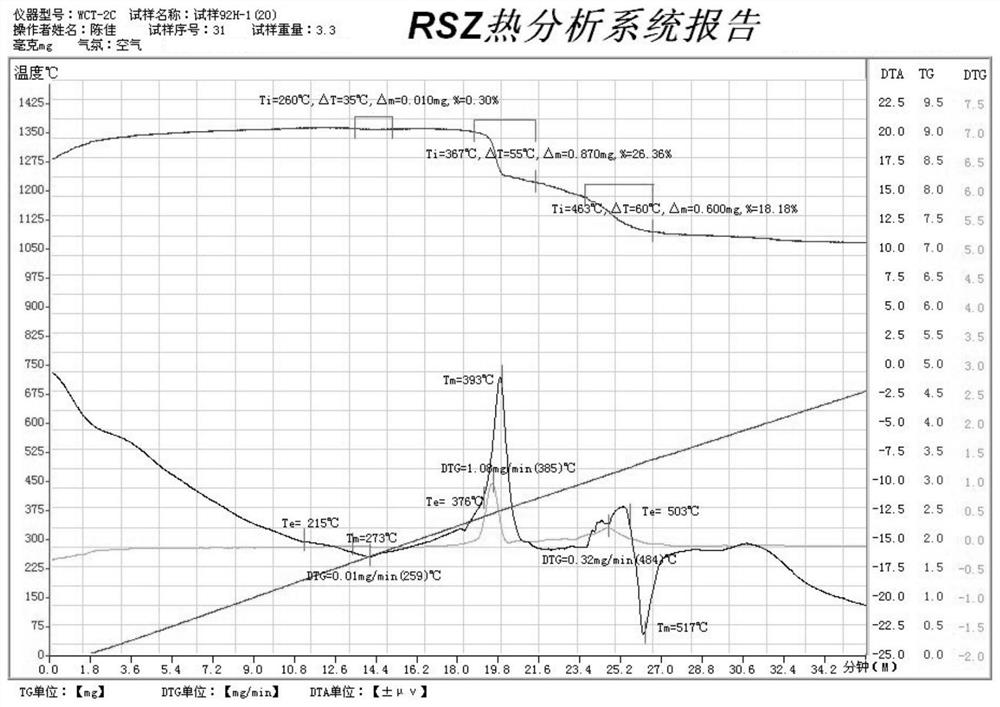

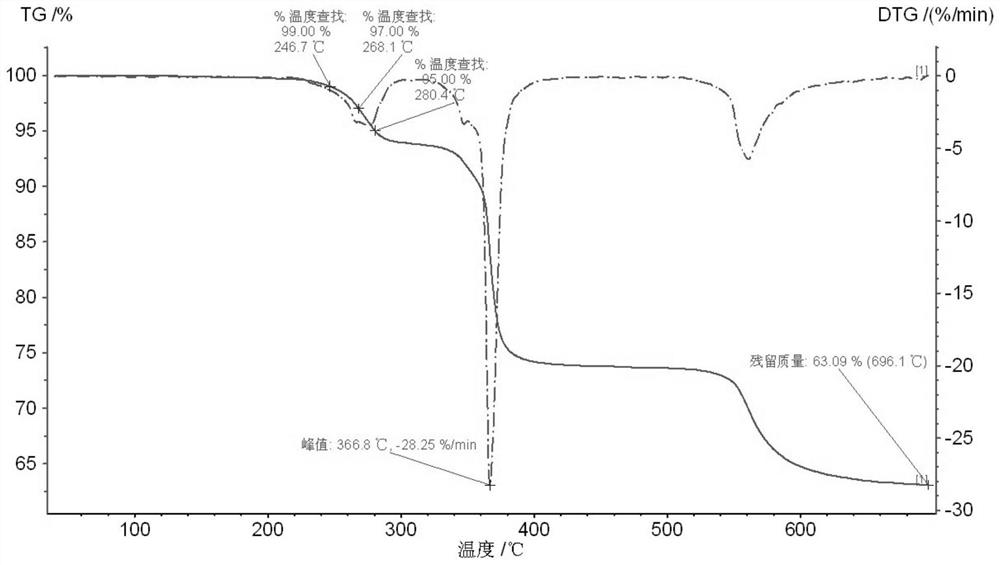

[0103] The resulting product was subjected to RSC thermal analysis, and the results were as follows: figure 1 Shown, this spectrogram and the RSC figure (such as figure 2 Shown) contrast, it can be seen that: the aluminum methylcyclohexyl hypophosphite obtained by the inventive method is consistent with the product of normal production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com