Graphitized carbon layer confined multi-element platinum alloy catalyst and preparation method thereof

A graphitized carbon and catalyst technology, applied in the fields of nano-catalysis and material chemistry, can solve problems such as affecting the initial activity and stability of platinum alloy catalysts, excessive growth, and easy agglomeration of PtM nanoparticles, achieving easy batch preparation, improving Dispersibility, the effect of relieving nanoparticle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a method of preparing a polycyclic platinum alloy catalyst in a graphitized carbon layer, which includes the following steps:

[0035] Step 1, multi-component precursor mixing: a carbon source precursor, a nitrogen source precursor, a transition metal M precursor, mix well in a first solvent, to obtain a dispersion, and then dry the dispersion, and ground Solid powder as a multi-component precursor. The dispersion dried a water bath to evaporate, dried, and the heating temperature of the water bath was 60 to 80 ° C.

[0036] The carbon source precursor comprises any one or two or more kinds of glucose, fructose or citric acid.

[0037] The nitrogen source precursor comprises any one or more mixtures of urea, monanide, dicyandiamide or melamine.

[0038] The transition metal M precursor comprises a transition metal sulfate, nitrate, hydrochloride or acetate mixture; the transition metal M comprises Fe, CO, Ni or Cu Any one or more or more kinds...

Embodiment 1

[0049] This embodiment relates to a method of preparing a carbon nanoplatinoid alloy catalyst, the method comprising the steps of:

[0050] Step 1: Weigh the glucose 10g, about 10 g and cobalt cobalt (control of the three weight ratio of 10: 10: 1), dissolved in 1000 ml of deionized water, ultrasonic dispersion 30min after being placed at 60 ° C The water bath is performed, continuously mechanically stirred during the process, and the sample evaporation is completely, dried, and the solid powder is ground.

[0051] Step 2: Place the solid powder of step 1 in the tube furnace, the firing temperature is 700 ° C, continuous heating for 1 h, and passes into nitrogen as a protective gas.

[0052] Step 3: Mix the solid powder obtained by step 2 with a propionate (according to the weight volume ratio of 1: 2), the ultrasonic dispersion is placed in the reaction flask in the reaction flask, and the temperature is heated to 120 ° C, add A certain amount of chloroplatinic acid solution (con...

Embodiment 2

[0056] This example is a variation of the first embodiment, and other embodiments are in the same embodiment, and the transition metal precursor in step 1 is changed from cobalt acetate and cobalt.

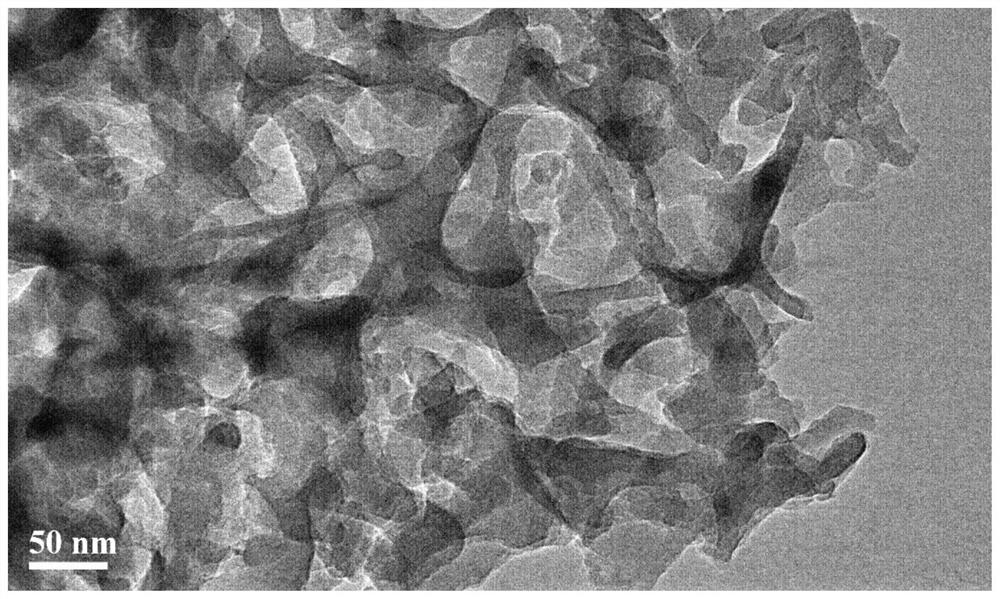

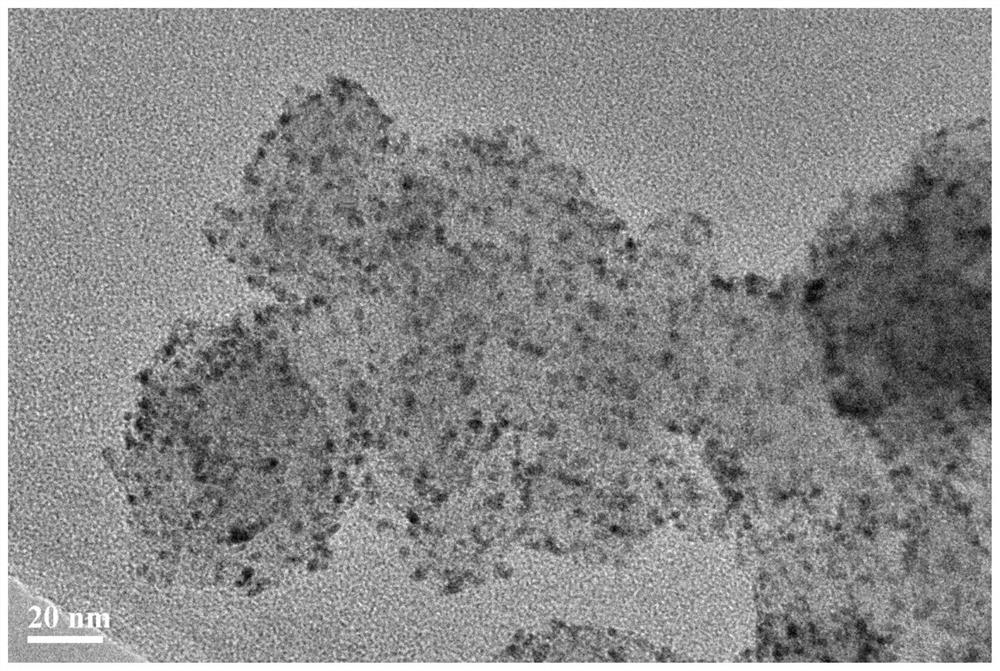

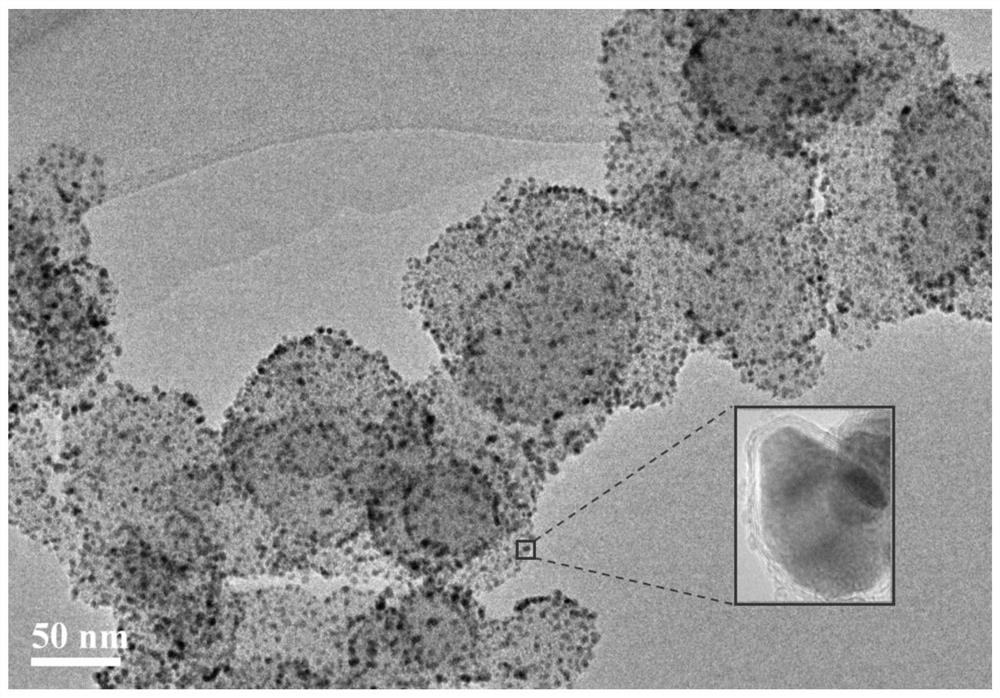

[0057] Effect: The platinum alloy catalyst prepared in this example is a three-dimensional PTCONI / NC @ C catalyst coated with a graphitized carbon layer structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com