Process for preparing D-glucosamine hydrochloride from biomass

A technology of glucosamine hydrochloride and biomass, which is applied in the preparation of amino sugars, sugar derivatives, sugar derivatives, etc., to achieve the effects of improving the utilization rate of raw materials, increasing the yield, and promoting hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

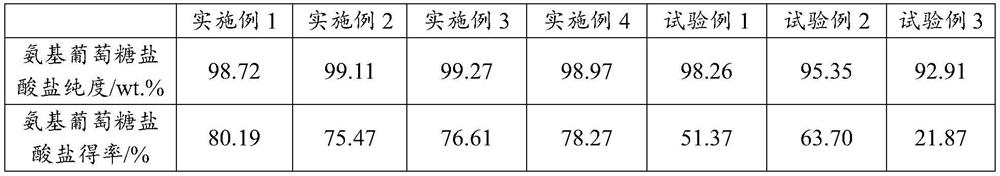

Examples

Embodiment 1

[0028] A kind of technique that utilizes biomass to prepare D-glucosamine hydrochloride comprises the steps:

[0029] (1) Wash the shrimp shells with clean water, then dry them at 50°C until there is no obvious residual moisture on the surface of the shrimp shells, then mix the shrimp shells with hydrochloric acid with a mass concentration of 15% to decalcify the shrimp shells, and wait until there is no residual moisture in the shrimp shells. Add excess sodium carbonate (mass concentration is 25%) after the air bubbles are exposed, then the reaction system is heated to 80 ℃ for further degreasing and deproteinization of the shrimp shells, and the shrimp shells are filtered out and the residues on the surface are removed by washing the shrimp shells with clear water, and then at 50 Dry the shrimp shells at ℃ to obtain chitin for later use.

[0030] (2) The chitin, ammonium chloride, ethanol and water obtained in step (1) are used to form a reaction system together, and the rea...

Embodiment 2

[0034] A kind of technique that utilizes biomass to prepare D-glucosamine hydrochloride comprises the steps:

[0035] (1) Wash the shrimp shells with clean water, then dry them at 55°C until there is no obvious residual moisture on the surface of the shrimp shells, and then mix the shrimp shells with hydrochloric acid with a mass concentration of 15% to decalcify the shrimp shells. Add excess sodium carbonate (mass concentration is 35%) after the air bubbles are exposed, then the reaction system is heated to 75 ℃ for further degreasing and deproteinization of the shrimp shells, and the shrimp shells are filtered out and the residues on the surface are removed by washing the shrimp shells with clear water, and then at 55 Dry the shrimp shells at ℃ to obtain chitin for later use.

[0036] (2) The chitin, ammonium chloride, ethanol and water obtained in step (1) are used to form a reaction system together, and the reaction system is placed in a high-pressure reactor with a polyte...

Embodiment 3

[0040] A kind of technique that utilizes biomass to prepare D-glucosamine hydrochloride comprises the steps:

[0041] (1) Wash the shrimp shells with clean water, then dry them at 60°C until there is no obvious residual moisture on the surface of the shrimp shells, and then mix the shrimp shells with hydrochloric acid with a mass concentration of 20% to decalcify the shrimp shells. Add excess sodium carbonate (mass concentration is 30%) after the air bubbles are exposed, then the reaction system is heated to 70°C for further degreasing and deproteinization of the shrimp shells, and the shrimp shells are filtered out and the residues on the surface are removed by washing the shrimp shells with clear water, then at 60 Dry the shrimp shells at ℃ to obtain chitin for later use.

[0042] (2) The chitin, ammonium chloride, methanol and water obtained in step (1) are used to form a reaction system together, and the reaction system is placed in a high-pressure reactor with a polytetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com