Selenium-doped lithium-rich manganese-based positive electrode material as well as preparation method and application thereof

A cathode material, lithium-rich manganese-based technology, applied in the field of preparation of lithium-rich manganese-based cathode materials, can solve the problems of poor rate performance, capacity and voltage decay, etc., to alleviate electrolyte decomposition, suppress capacity decay and voltage drop, and prepare simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Its preparation method comprises the following steps:

[0049] S1. Mix the precursor and the lithium source in a dry environment for 0.5-1 h, and mix them uniformly to obtain a mixture; wherein, the mass excess coefficient of the lithium source is 3-10%; the lithium source is a common lithium-containing compound, including But not limited to lithium carbonate, lithium hydroxide monohydrate, lithium hydroxide, lithium nitrate, etc.; the precursor can be replaced by carbonate, oxalate, acetate or hydroxide of nickel-cobalt-manganese in different proportions;

[0050] S2. Put the mixture obtained in step S1 into a calcination device for calcination treatment under an oxygen atmosphere. After the calcination, cool to room temperature with the furnace to obtain a lithium-rich manganese-based positive electrode material; the calcination adopts a two-stage calcination method: the first The first stage of calcination is calcination at 500~700 ℃ for 5~10 h, and the second stage ...

Embodiment 1

[0058] A method for preparing a lithium-rich manganese-based positive electrode material, comprising the following steps:

[0059] (1) Add 2 g precursor Mn 0.672 Ni 0.164 co 0.164 CO 3 with 1.02 g LiOH·H 2 O was placed in an agate mortar and mixed for 1 h in a dry environment to obtain a mixture precursor;

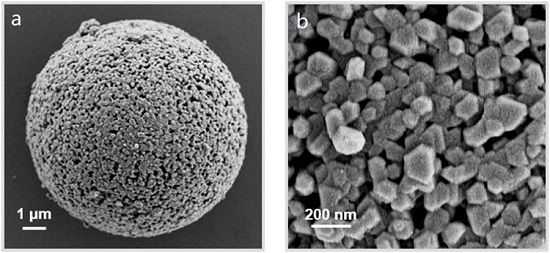

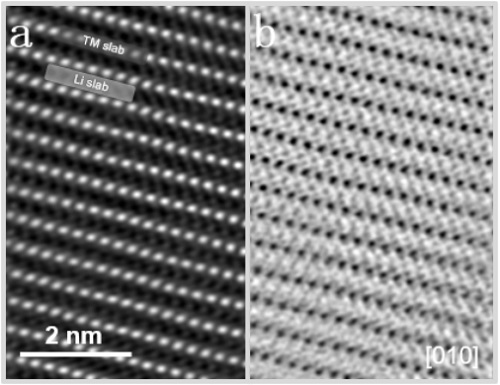

[0060] (2) Transfer the homogeneous mixture precursor in step (1) to the corundum ark, and then place it in an oxygen atmosphere tube furnace for calcination. The calcination condition is 5 ℃ / min to 500 ℃, and after constant temperature for 5 h, The temperature was raised to 900 °C at 5 °C / min, kept at a constant temperature for 12 h, and cooled to room temperature with the furnace to obtain a lithium-rich manganese-based cathode material sample, which was named LRM.

Embodiment 2

[0062] A preparation method of a selenium-doped lithium-rich manganese-based positive electrode material, comprising the following steps:

[0063] S1. Mix 2 g of the lithium-rich manganese-based positive electrode material prepared in Example 1 with 20 mg of commercial selenium powder for 2 h, transfer the uniformly mixed material to a corundum ark, and then place it in a tube furnace with an argon atmosphere Medium calcination, the calcination condition is 2 ℃ / min heating up to 500 ℃, constant temperature for 5 h, gas flow 2 mL / min;

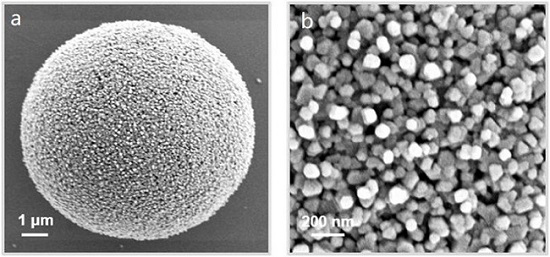

[0064] S2. Take the sample after calcination in step S1 and add it to 10 mL of carbon disulfide solution at 500 r / min, stir for 5 h, filter and wash with alcohol for 4 times, and vacuum-dry at 120 °C for 12 h to obtain a lithium-rich solution doped with selenium anions. The manganese-based cathode material is named Se-LRM, and electron spectroscopy analysis shows that the mass fraction of selenium is 0.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com