Multi-block binder as well as preparation method and application thereof

A binder and multi-block technology, which is applied in the field of lithium-ion batteries, can solve the problems of silicon-based negative electrode sheet dropping, reducing the expansion rate of silicon-based negative electrode sheet, and low glass transition temperature of the binder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

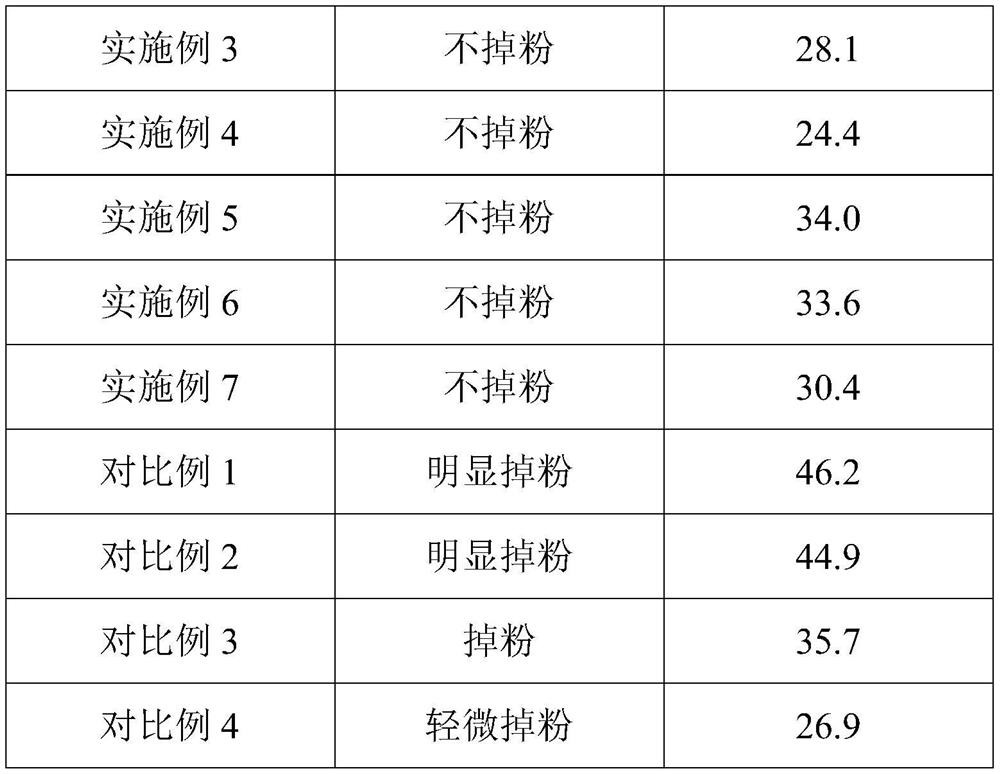

Embodiment 1

[0071] This embodiment provides a multi-block binder, which uses polymethyl methacrylate-isooctyl acrylate-acrylamide as repeating units, has a molecular weight of 1.8 million, and a glass transition temperature of 75°C. In the multi-block binder, the mass fraction of methyl methacrylate is 50%, the mass fraction of isooctyl acrylate is 30%, and the mass fraction of acrylamide is 20%.

[0072] The preparation method of described binder comprises the following steps:

[0073] (1) Methyl methacrylate and isooctyl acrylate are mixed with water in a mass ratio of 5:3 to obtain a mixed solution;

[0074] (2) The mixed solution obtained in step (1) is placed in a 40°C water bath and stirred, and after the temperature is stabilized, dibenzoyl peroxide and chloroform are added thereto while stirring, and the dibenzoyl peroxide The mass percentages of acyl chloride and chloroform are both 0.1%, the stirring speed is 200rpm, and the reaction time is 4h to obtain the reaction solution; ...

Embodiment 2

[0077] This embodiment provides a multi-block binder, which uses polyacrylonitrile-isooctyl acrylate-acrylamide as repeating units, has a molecular weight of 1.6 million, and a glass transition temperature of 80°C. In the multi-block binder, the mass fraction of acrylonitrile is 35%, the mass fraction of isooctyl acrylate is 30%, and the mass fraction of acrylamide is 35%.

[0078] The preparation method of described binder comprises the following steps:

[0079] (1) acrylonitrile and isooctyl acrylate are mixed with water in a mass ratio of 3.5:3 to obtain a mixed solution;

[0080](2) The mixed solution obtained in step (1) is placed in a 55°C water bath and stirred, and after the temperature is stabilized, sodium lauryl sulfate and isopropanol are added thereto while stirring, the lauryl sulfate The mass percentages of sodium and isopropanol are 1% and 2.5% respectively, the stirring speed is 600rpm, the reaction time is 2.5h, and the reaction solution is obtained;

[008...

Embodiment 3

[0083] This embodiment provides a multi-block binder, which uses polymethyl methacrylate-butyl acrylate-acrylamide as repeating units, has a molecular weight of 1.9 million, and a glass transition temperature of 90°C. In the multi-block binder, the mass fraction of methyl methacrylate is 40%, the mass fraction of butyl acrylate is 20%, and the mass fraction of acrylamide is 40%.

[0084] The preparation method of described binder comprises the following steps:

[0085] (1) Methyl methacrylate and butyl acrylate are mixed with water in a mass ratio of 6:3 to obtain a mixed solution;

[0086] (2) The mixed solution obtained in step (1) is placed in a 70°C water bath and stirred, and after the temperature is stabilized, azobisisobutyronitrile and chloroform are added thereto while stirring, the azobisisobutyronitrile The mass percentages of nitrile and chloroform are respectively 2% and 5%, the speed of the stirring is 1000rpm, the reaction time is 1h, and the reaction solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap