A core-shell structure hydrodechlorination catalyst, its preparation method and application

A technology of hydrodechlorination and core-shell structure, which is applied in the application field of hydrodechlorination catalysts in gas-phase hydrodechlorination reactions, and can solve the problem of inability to selectively obtain chlorotrifluoroethylene, large selectivity differences, and limited To achieve the effect of improving catalytic efficiency and stable running time of catalytic reaction, reducing bed pressure drop and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

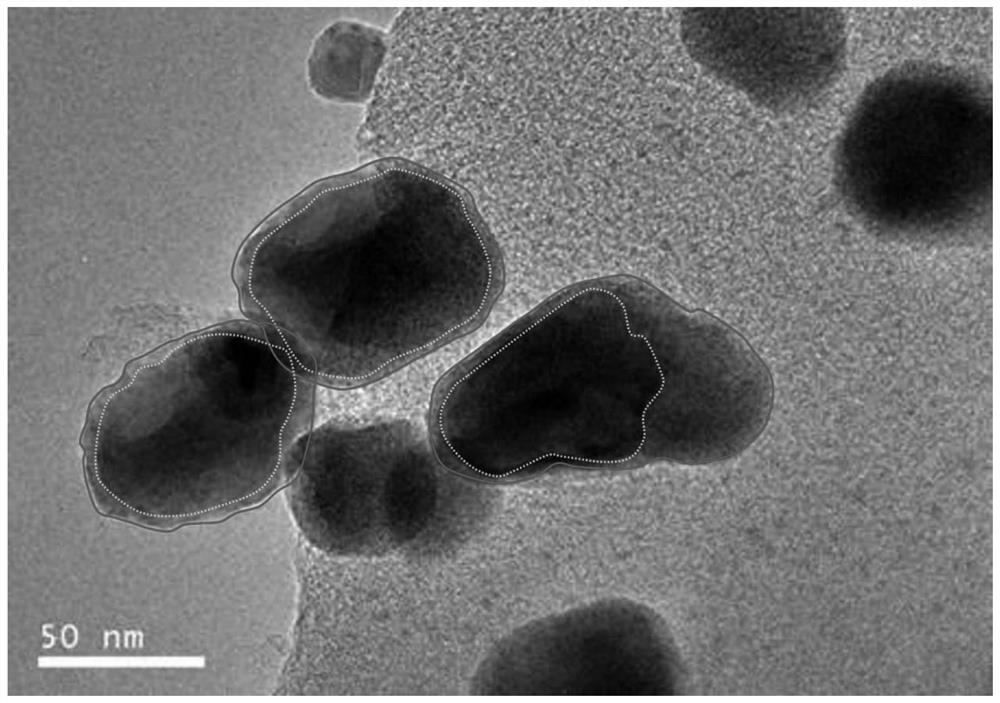

Image

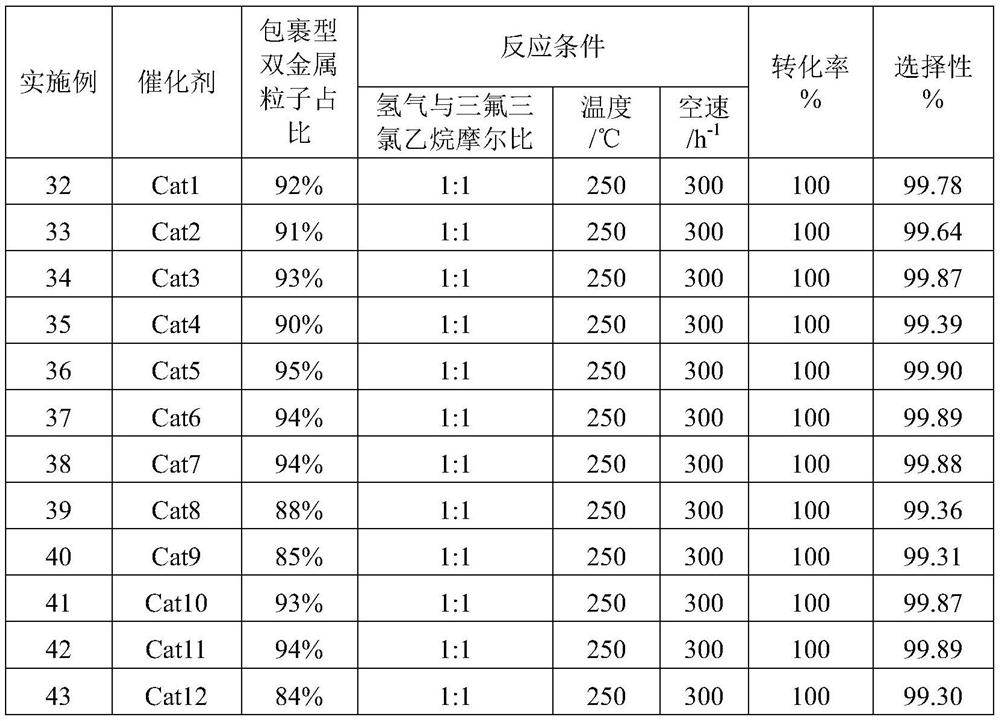

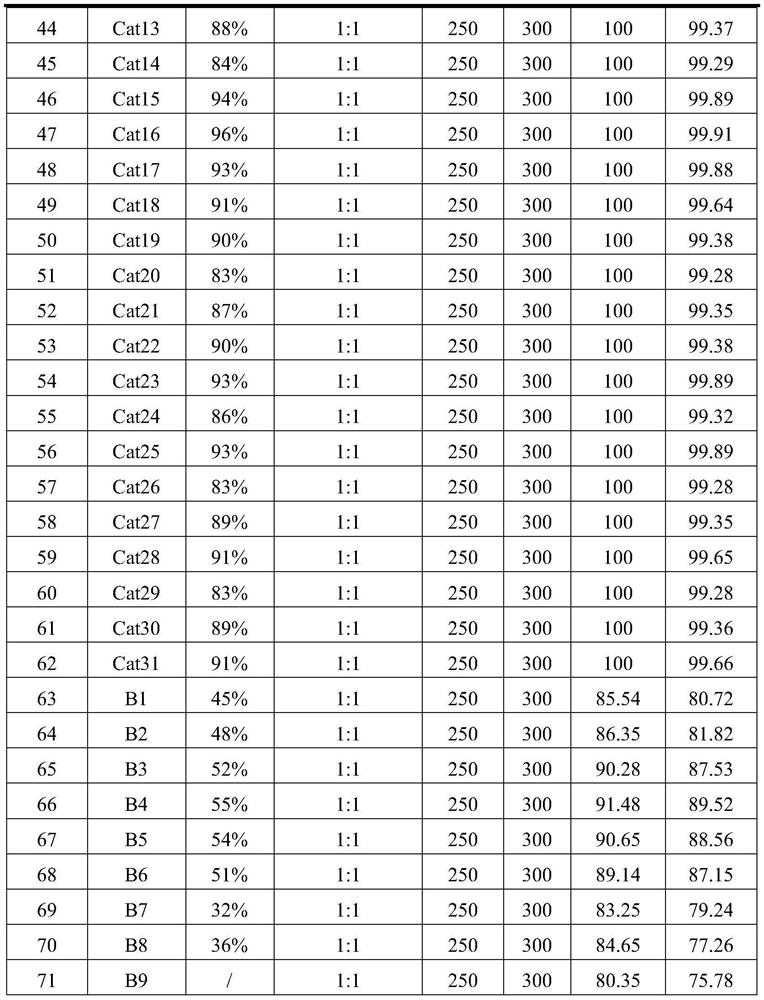

Examples

Embodiment 1

[0053] Preparation of hydrodechlorination catalyst:

[0054] S1. Active metal loading: the monolithic activated carbon carrier (coal, 1000m 2 / g, ash content 2.0wt%, pore density 30 pores / cm 2 , density 0.5g / mL), rinsed with deionized water, immersed in chloropalladium acid aqueous solution, the palladium content is 1.0% of the monolithic activated carbon carrier, and the volume ratio of the total volume of the immersion solution to the monolithic activated carbon carrier is 2:1 . Start stirring, heat up to 50°C, take out after immersion for 3 hours; let stand for 15 hours at 30°C and air humidity of 70% to drain, and then blow with a nitrogen flow with a flow rate of 0.5m / s (containing 0.1v / v oxygen) Sweep for 1 hour.

[0055] S2. Second metal loading: 1) Active metal reduction: place the active metal-loaded monolithic activated carbon carrier purged with nitrogen flow in a high-pressure reactor, immerse it in ethylene glycol solution, and add magnetrons to the bottom of t...

Embodiment 2

[0061] The operation of this example is the same as that of Example 1, except that the material of the monolithic activated carbon carrier adopts wood instead of coal to prepare a hydrodechlorination catalyst, which is denoted as cat2.

[0062] According to TEM characterization, in the hydrodechlorination catalyst prepared in this implementation, 91% of the second metal particles are in the encapsulated bimetallic structure.

Embodiment 3

[0064] The operation of this example is the same as that of Example 1, except that the specific surface area of the monolithic activated carbon carrier is 1200 m 2 / g, ash content 1.8wt%, pore density 20 pores / cm 2 , the density is 0.6g / mL. The hydrodechlorination catalyst was prepared and denoted as cat3.

[0065] According to TEM characterization, in the hydrodechlorination catalyst prepared in this implementation, 93% of the second metal particles are in the encapsulated bimetallic structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com