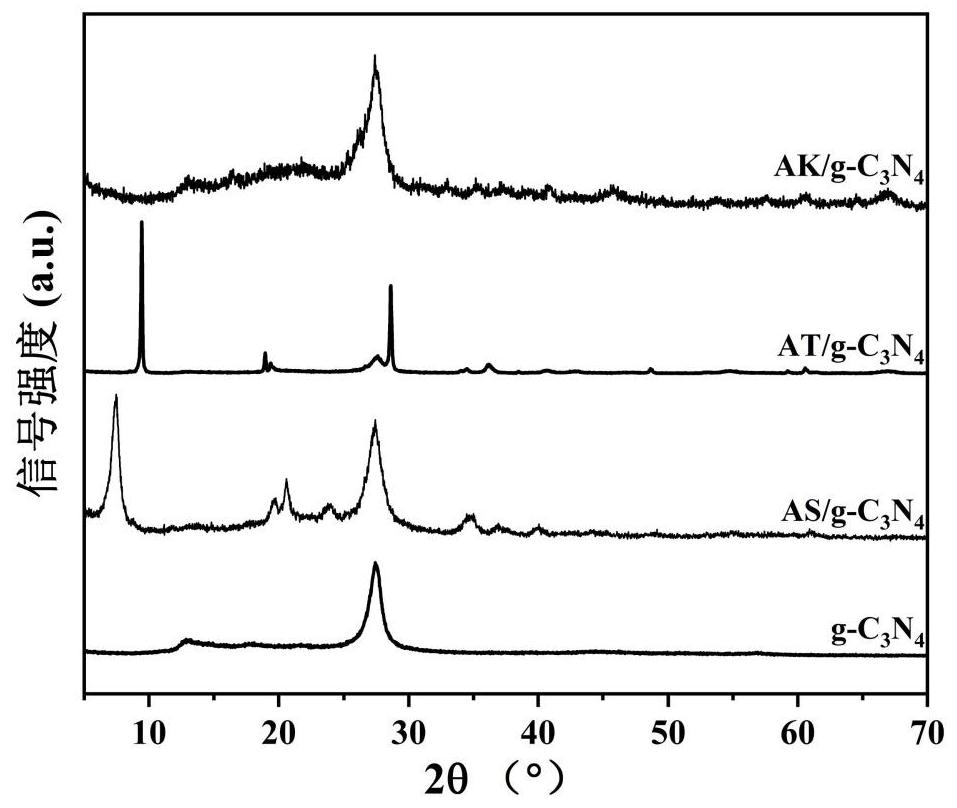

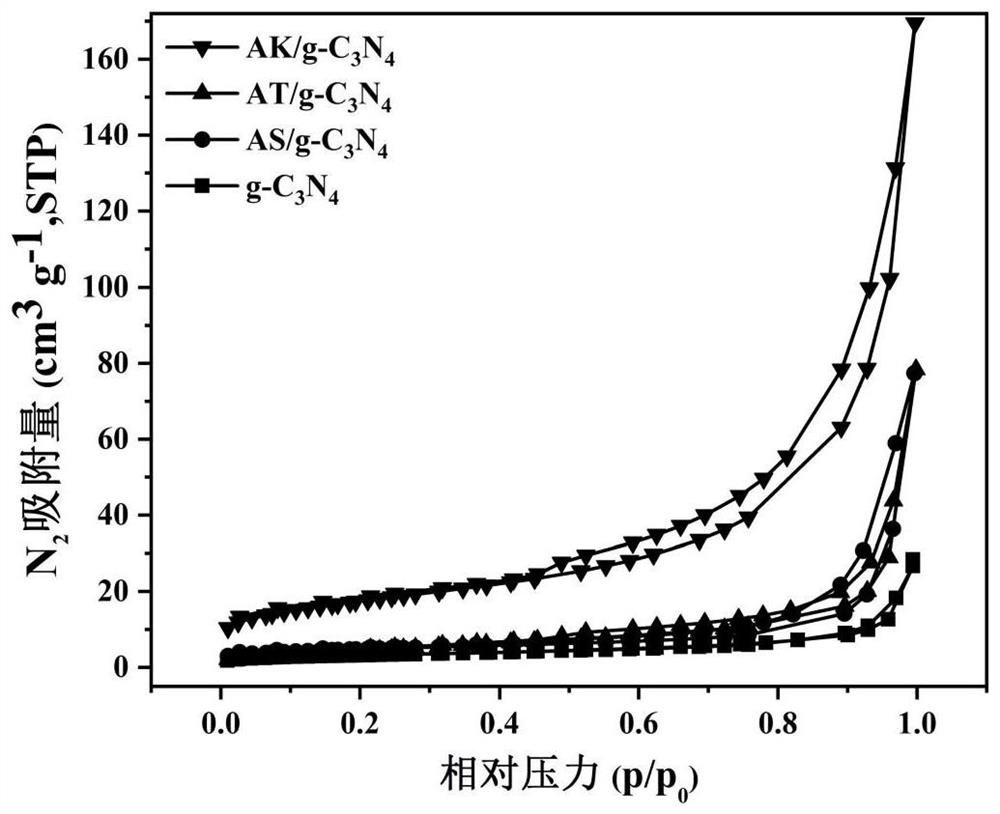

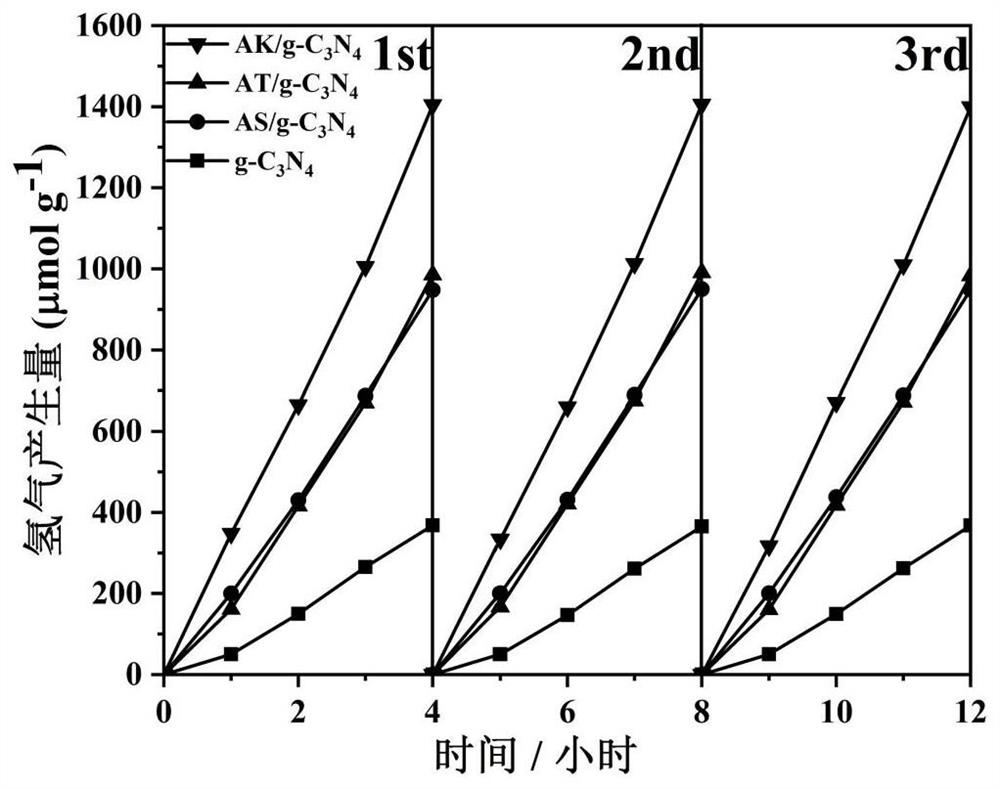

Preparation method of acid-modified silicate mineral-loaded graphite-phase carbon nitride photocatalyst

A technology based on silicate minerals and phase carbon nitride, which is applied in the field of photocatalytic materials and can solve the problems of high cost, long preparation period and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Prepare 150mL of aqueous solution of 1M hydrochloric acid and 5mL of aqueous solution of 1M sodium hydroxide, stir and disperse evenly;

[0031] (2) Weigh 15 g of sepiolite powder, add 150 mL of hydrochloric acid obtained in step (1) into the sepiolite powder, stir at room temperature for 48 h, and then centrifuge to remove the supernatant. Then add deionized water to the sepiolite powder and stir for 30min to make it evenly dispersed, remove the supernatant after centrifugation, and repeat washing with deionized water for 4 times; after adding deionized water for the 5th time, use step (1) Sodium hydroxide solution adjusted the pH to about 7, centrifuged to remove the supernatant, added deionized water and repeated centrifuged for 3 times, dried the precipitate in a blast drying oven at 60°C for 12 hours, and prepared acid-modified sepiolite powder precursor after grinding body;

[0032] (3) 500 mg of the precursor and 1 g of melamine prepared in step (2) were dis...

Embodiment 2

[0035] (1) Prepare 150mL of aqueous solution of 1M hydrochloric acid and 5mL of aqueous solution of 1M sodium hydroxide, stir and disperse evenly;

[0036] (2) Weigh 15 g of talc powder, add 150 mL of hydrochloric acid obtained in step (1) into the talc powder, stir at room temperature for 48 h, and then centrifuge to remove the supernatant. Then add deionized water to the talc powder and stir for 30min to make it evenly dispersed, remove the supernatant after centrifugation, and repeat washing with deionized water for 4 times; after adding deionized water for the 5th time, use the hydrogen Sodium oxide solution adjusted the pH to about 7, centrifuged to remove the supernatant, added deionized water and repeated centrifuged 3 times, dried the precipitate in a blast drying oven at 60°C for 12 hours, and prepared the acid-modified talc powder precursor after grinding;

[0037] (3) 500 mg of the precursor and 1 g of melamine prepared in step (2) were dispersed in 30 ml of absolut...

Embodiment 3

[0039] (1) Prepare 150mL of aqueous solution of 1M hydrochloric acid and 5mL of aqueous solution of 1M sodium hydroxide, stir and disperse evenly;

[0040] (2) Weigh 15 g of kaolin powder, add 150 mL of hydrochloric acid obtained in step (1) into the kaolin powder, stir at room temperature for 48 h, and then centrifuge to remove the supernatant. Then add deionized water to the kaolin powder and stir for 30 minutes to make it evenly dispersed, remove the supernatant after centrifugation, and repeat washing with deionized water for 4 times; after adding deionized water for the 5th time, use the hydroxide Adjust the pH to about 7 with the sodium solution, remove the supernatant by centrifugation, add deionized water and repeat the centrifugation for 3 times, dry the precipitate in a blast drying oven at 60°C for 12 hours, and prepare the acid-modified kaolin powder precursor after grinding;

[0041] (3) 600 mg of the precursor and 1 g of melamine prepared in step (2) were dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com