A modified silicon oxide/carbon nanotube composite negative electrode material and its preparation method

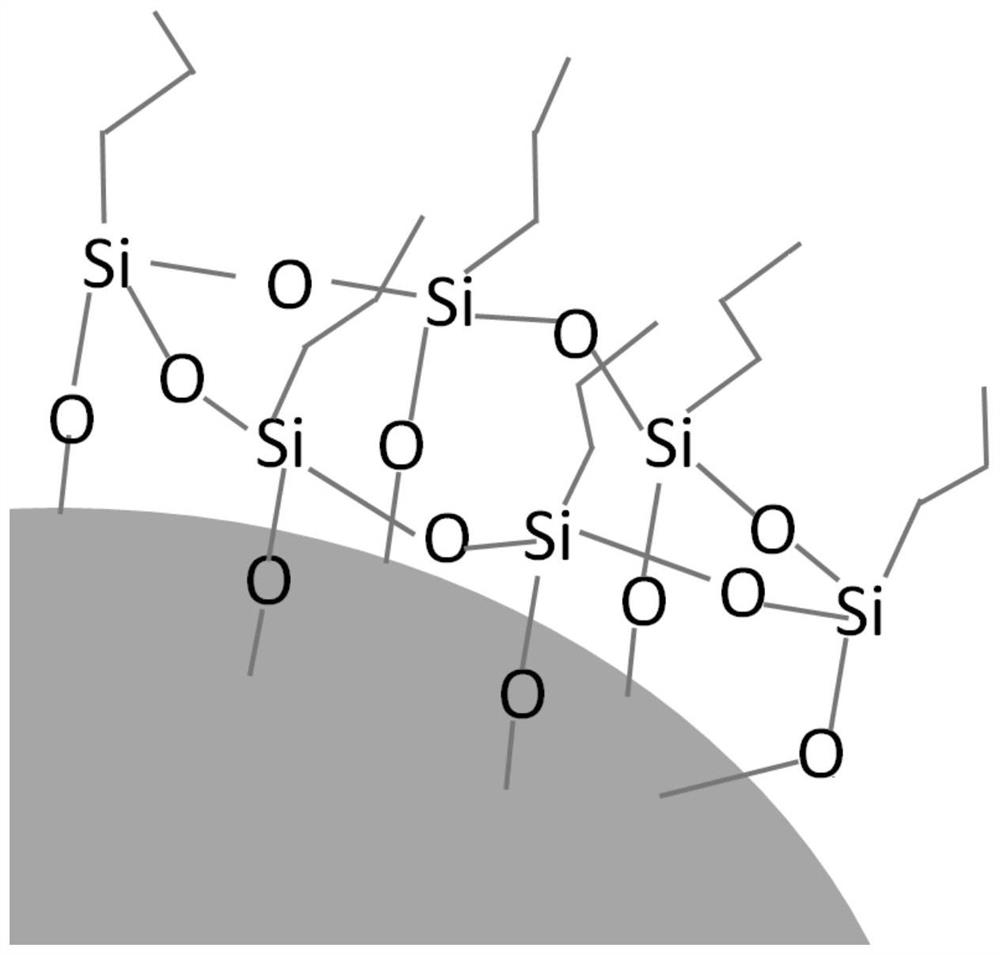

A technology of carbon nanotube composite and silicon oxide, which is applied in the field of lithium-ion batteries, can solve the problems of difficult grafting, difficulty in uniform dispersion, and high surface energy, so as to improve cycle stability, improve structural stability, and inhibit volume expansion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take a certain amount of deionized water in a beaker, add 3g of silane coupling agent KH-560 to the beaker, adjust the pH value to 6.5 with sodium hydroxide and acetic acid, and let it stand for 1 hour; The siliceous particles were placed in a beaker, and equal amounts of ethanol and water were added respectively, and ultrasonically dispersed for 30 minutes; the uniformly dispersed siliceous oxide and the hydrolyzed silane coupling agent KH-560 were mixed and poured into the reaction kettle, and then 0.3 g was added. The surfactant dodecyl dimethyl betaine, passed through N 2 , heated to 140°C, stirred at this temperature for 4h, suction filtered, washed with ethanol, and dried in a vacuum drying oven at 80°C to obtain modified silicon oxide.

[0036] Acidification of carbon nanotubes: Weigh 5g of carbon nanotubes (radius distribution 40-60nm, length distribution 4-6μm, purity 99%) into a 250ml round bottom flask, add 45ml concentrated HNO 3 , stir evenly, then slowly ...

Embodiment 2

[0042] Take a certain amount of deionized water in a beaker, add 1.5g of silane coupling agent KH-560 to the beaker, adjust the pH value to 6.5 with sodium hydroxide and acetic acid, and let stand for 1h; weigh 30g of 200nm particle size The silicon oxide particles were placed in a beaker, and equal amounts of ethanol and water were added respectively, and ultrasonically dispersed for 30 minutes; the uniformly dispersed silicon oxide and the hydrolyzed silane coupling agent KH-560 were mixed and poured into the reaction kettle, and then 0.3 g of the surfactant dodecyl dimethyl betaine, passed through N 2 , heated to 140°C, stirred at this temperature for 4h, suction filtered, washed with ethanol, and dried in a vacuum drying oven at 80°C to obtain modified silicon oxide.

[0043] The remaining steps are the same as in Example 1, and finally powder sample B is obtained.

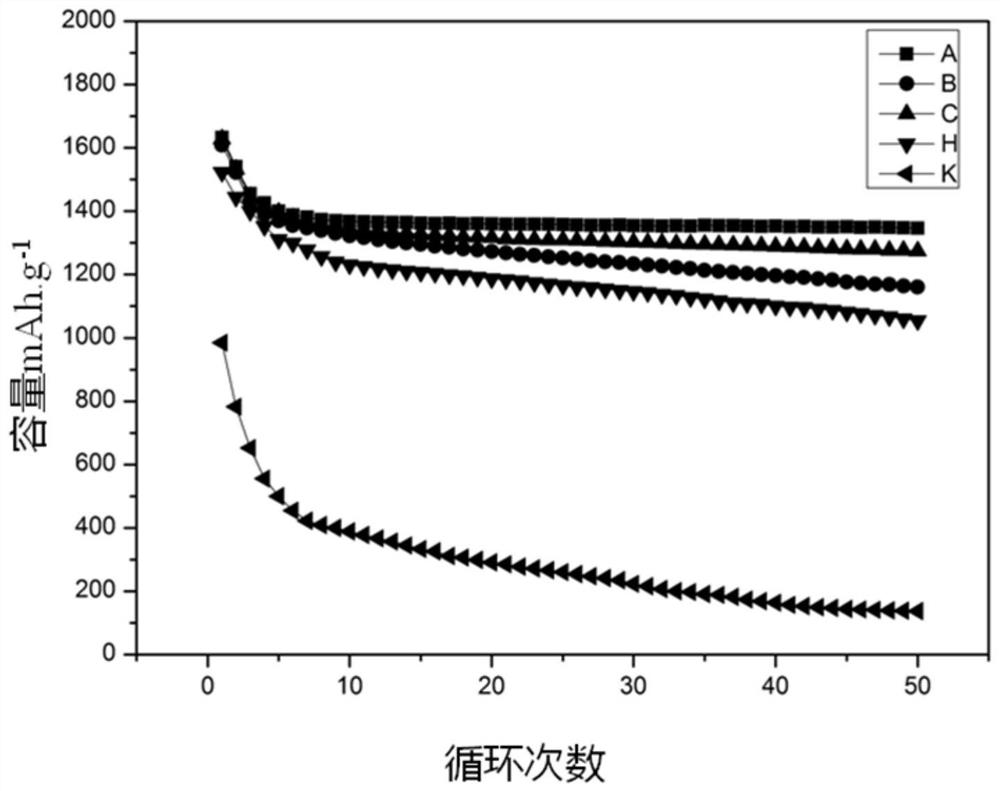

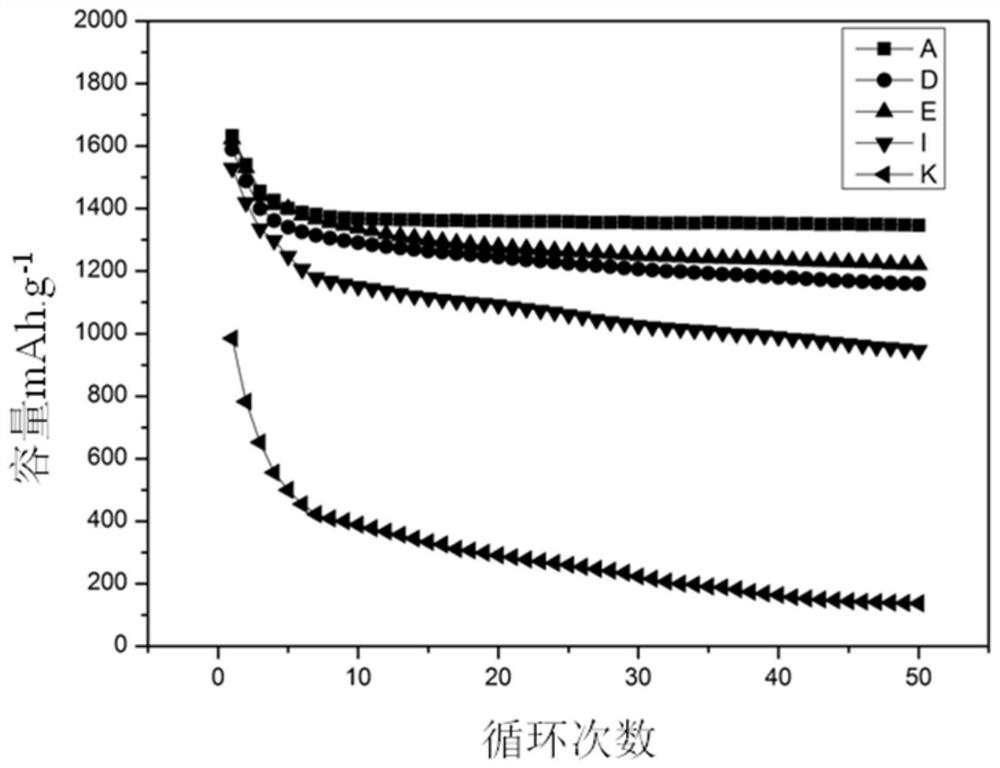

[0044] The button battery was assembled with sample B as the negative active material, and the constant cu...

Embodiment 3

[0046] Take a certain amount of deionized water in a beaker, add 4.5g of silane coupling agent KH-560 to the beaker, adjust the pH value to 6.5 with sodium hydroxide and acetic acid, and let stand for 1h; weigh 30g of 200nm particle size The silicon oxide particles were placed in a beaker, and equal amounts of ethanol and water were added respectively, and ultrasonically dispersed for 30 minutes; the uniformly dispersed silicon oxide and the hydrolyzed silane coupling agent KH-560 were mixed and poured into the reaction kettle, and then 0.3 g of the surfactant dodecyl dimethyl betaine, passed through N 2 , heated to 140°C, stirred at this temperature for 4h, suction filtered, washed with ethanol, and dried in a vacuum drying oven at 80°C to obtain modified silicon oxide.

[0047] The remaining steps are the same as in Example 1, and finally powder sample C is obtained.

[0048] A button battery was assembled with sample C as the negative active material, and the constant curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com