Preparation method of photoresist film-forming resin and photoresist composition thereof

A film-forming resin and photoresist technology, applied in the field of photoresist, can solve the problems such as the heat resistance and etching resistance are not as strong as that of the benzene ring structure, the purification conditions are very strict, and the film uniformity is not good. Good edge roughness, low price, improved resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

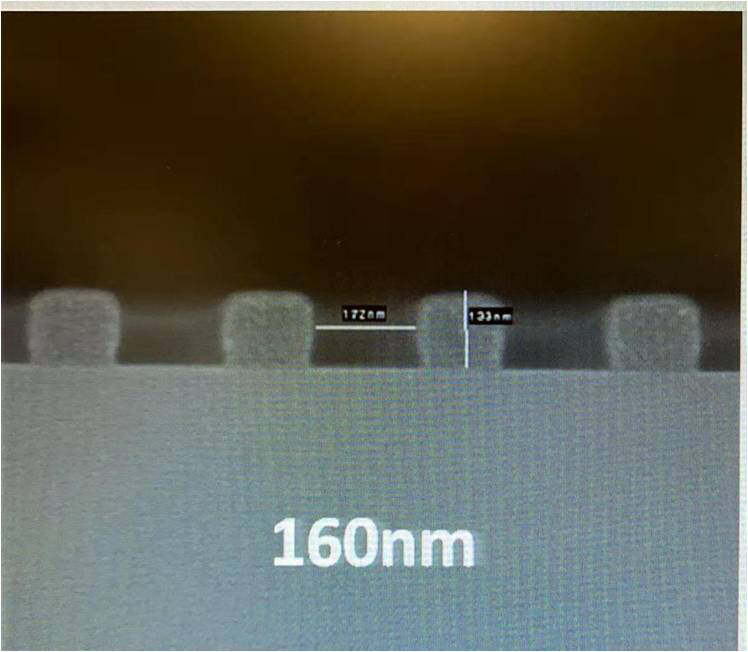

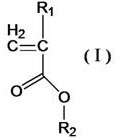

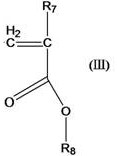

Image

Examples

preparation example Construction

[0061] (1) Preparation experiment of photoresist film-forming resin

[0062] 1. Discussion experiments on the dosage of different reaction monomers

Embodiment 1

[0065] A preparation method of photoresist film-forming resin, comprising the following steps:

[0066] (1) Add monomer A, monomer B, monomer C, compound emulsifier (sodium lauryl sulfate and fatty alcohol poly Oxyethylene ether with a volume ratio of 1:2) and 400ml of water, nitrogen gas was introduced to remove the oxygen in the reaction system, high-speed stirring, reflux, and the temperature was raised to 40°C for about 30 minutes to pre-emulsify to obtain a pre-emulsion; among them, Said monomer A is trifluoroethyl methacrylate, and the consumption is 33.6g; said monomer B is tert-butyl methacrylate, and the consumption is 159.9g; Monomer C is cyclopentyl methacrylate, and the consumption is is 15.3g; the molar ratio of monomer A, monomer B and monomer C is 2:3:1; the amount of the composite emulsifier is 4% of the sum of the mass of monomer A, monomer B and monomer C, which is 8.35g;

[0067] (2) Raise the temperature of the pre-emulsion in step (1) to 80°C, reduce the...

Embodiment 2

[0074] The content of embodiment 2 is basically the same as embodiment 1, the difference is:

[0075] In step (1), the monomer A is trifluoroethyl methacrylate, and the dosage is 16.8 g; the monomer B is tert-butyl methacrylate, and the dosage is 159.9 g; the monomer C is methyl Cyclopentyl acrylate, the dosage is 15.3 g; the molar ratio of monomer A, monomer B and monomer C is 1:3:1; the dosage of the composite emulsifier is monomer A, monomer B and monomer 4% of the total mass of C is 7.68g; in step (2), the amount of ammonium persulfate is 0.2% of the total mass of monomer A, monomer B and monomer C, which is 0.38g.

[0076] Finally, the weight-average molecular weight of the photoresist film-forming resin was measured to be 8644 g / mol, and the molecular weight distribution was 1.71.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com