Preparation method and application of a photothermal conversion hydrogel

A photothermal conversion and hydrogel technology is applied in the field of photothermal conversion hydrogel preparation. , Excellent photothermal conversion effect, good recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

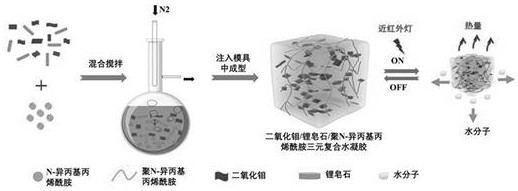

[0035] A kind of preparation method of photothermal conversion hydrogel, its preparation flow schematic diagram is as follows figure 1 shown, including the following steps:

[0036] (1) Disperse 30 mg of molybdenum dioxide in 10 mL of deionized water, ultrasonically treat it for 0.5 h, and stir for 3 h to obtain a molybdenum dioxide dispersion with a concentration of 3 mg / mL; the molybdenum dioxide is a commercially available reagent or according to the following method Prepared: after molybdenum trioxide and zinc powder are uniformly mixed in a weight ratio of 1:0.02, calcined at 400 ° C for 4 hours under nitrogen protection to obtain a black product, and then the black product is washed sequentially with hydrochloric acid solution, ammonia solution and water , to obtain a precipitate, which was dried at 50 °C to obtain molybdenum dioxide.

[0037] (2) Disperse 200 mg of hectorite in deionized water, ultrasonicate for 30 minutes to obtain a clear and transparent hectorite so...

Embodiment 2

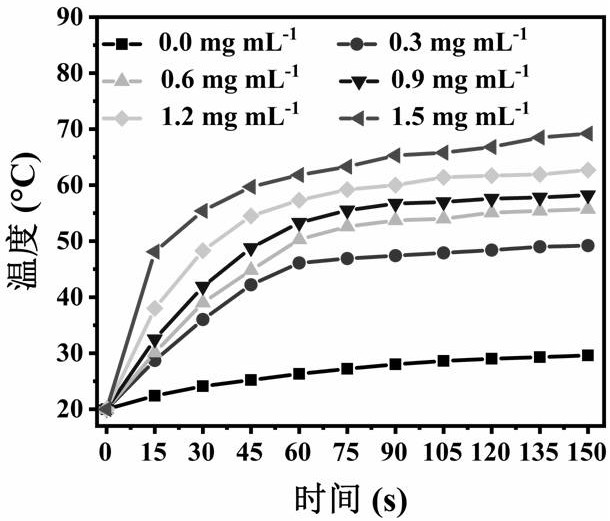

[0041] The content of Embodiment 2 is basically the same as that of Embodiment 1, except that:

[0042] In step (2), the dosage of the deionized water is 8.0 mL; the dosage of the molybdenum dioxide dispersion with a concentration of 3 mg / mL is 2.0 mL, and the concentration of molybdenum dioxide in the hydrogel is 0.6 mg / mL; In step (3), the mass ratio of molybdenum dioxide to N-isopropylacrylamide in the mixed prepolymerization solution is 0.006:1.

Embodiment 3

[0044] The content of Embodiment 3 is basically the same as that of Embodiment 1, except that:

[0045] In step (2), the dosage of the deionized water is 7.0 mL; the dosage of the molybdenum dioxide dispersion with a concentration of 3 mg / mL is 3.0 mL, and the concentration of molybdenum dioxide in the hydrogel is 0.9 mg / mL; In step (3), the mass ratio of molybdenum dioxide to N-isopropylacrylamide in the mixed prepolymerization solution is 0.009:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com